Connection terminal for PCB

A technology of PCB board and connection terminal, applied in the direction of connection, fixed connection, contact parts, etc., can solve the problem that the PCB board cannot realize detachable connection, etc., and achieve the effect of quick electrical connection and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

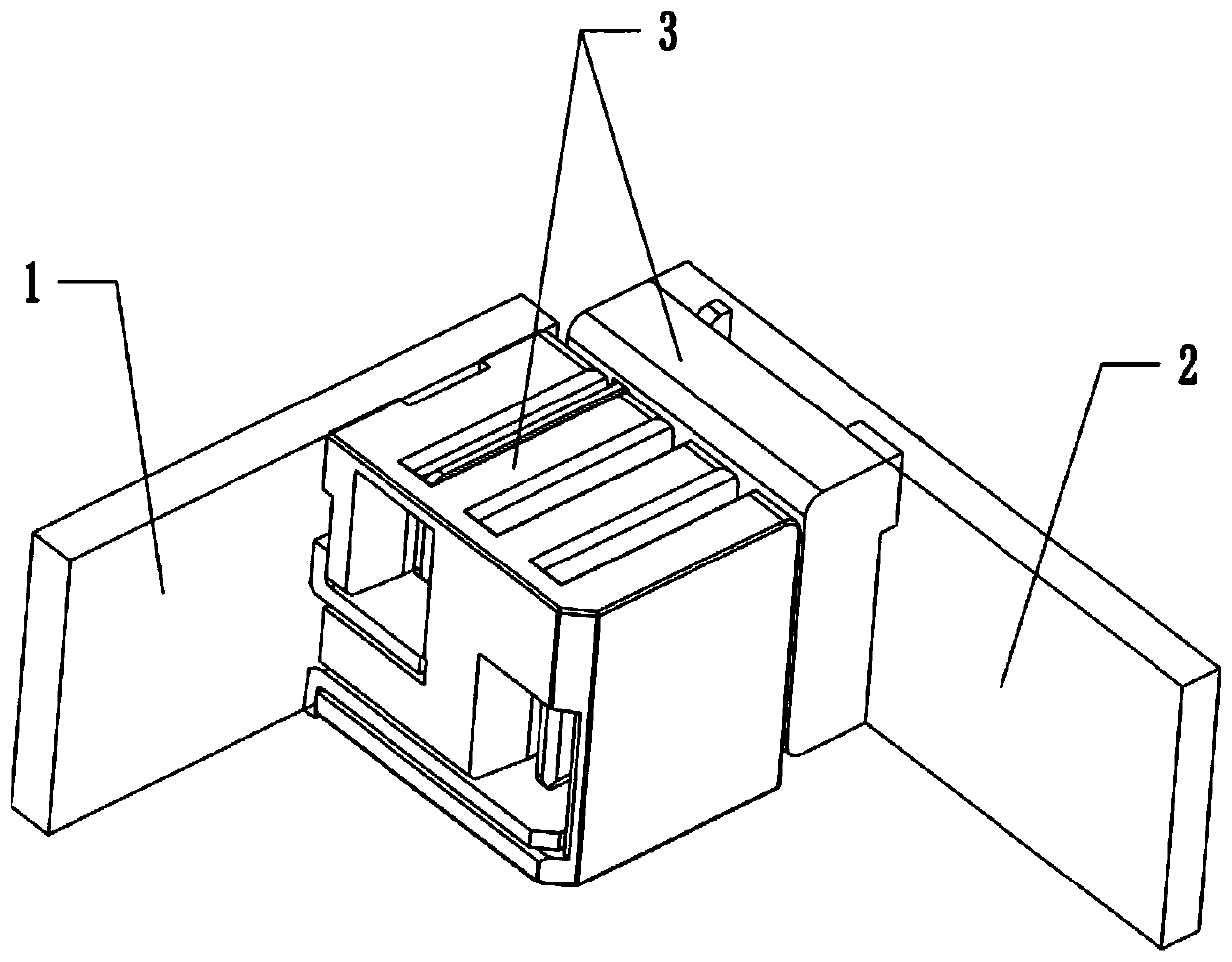

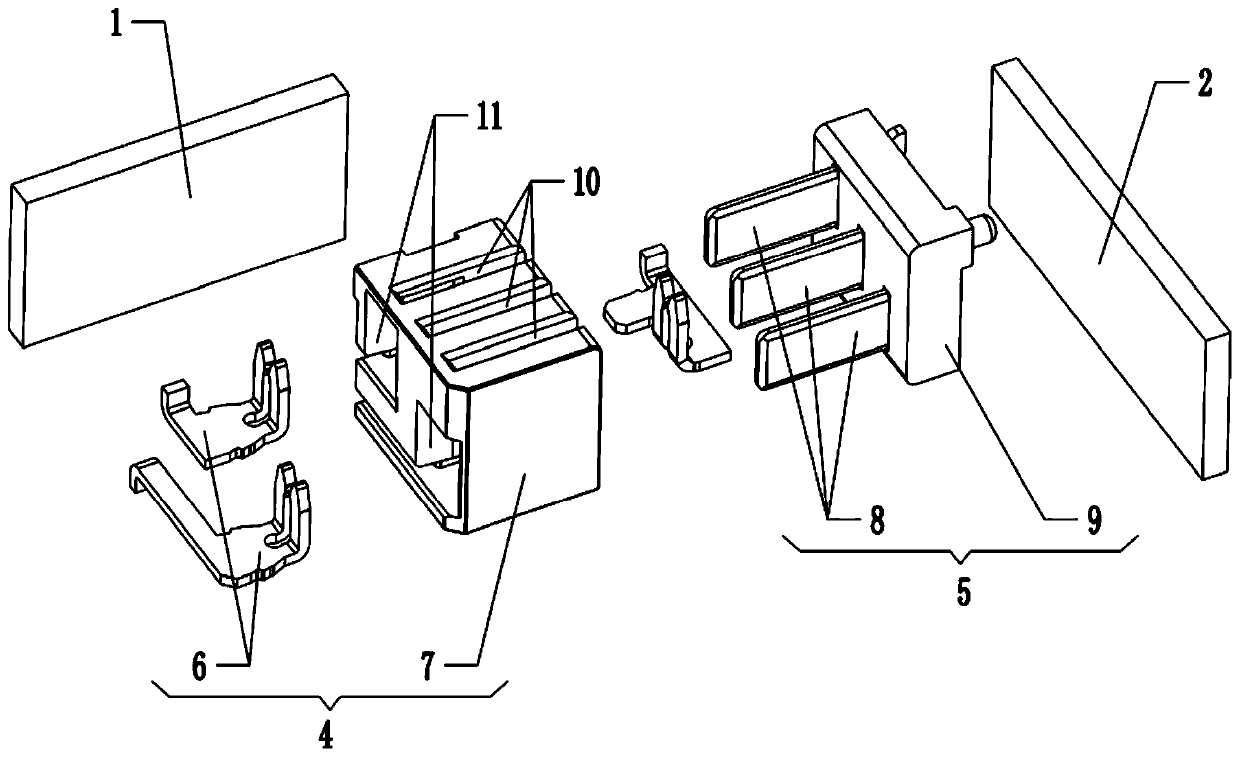

[0045] The angle between the first PCB board 1 and the second PCB board 2 is 90°, as follows:

[0046] Depend on Figure 1 to Figure 6 As shown, in this embodiment, a connection terminal for a PCB board is used to electrically connect the first PCB board 1 and the second PCB board 2, and the connection terminal 3 includes:

[0047] Female header assembly 4, which includes a female header housing 7 provided with a slot 10, and a conductive clip 6 configured on the female header housing 7 and supported on the first PCB board 1; the conductive clip 6 has a socket 10 The clamping section 13, and the connecting section 12 configured on the clamping section 13 and electrically connected to the first PCB board 1;

[0048] Male head assembly 5, which includes a male head housing 9 configured on the second PCB board 2, and a male plug 8 configured on the male head housing 9 and electrically connected to the second PCB board 2, the male plug 8 and the clamping section 13 matching;

...

no. 2 example

[0055] The angle between the first PCB board 1 and the second PCB board 2 is 90°, as follows:

[0056] Depend on Figure 8 to Figure 11 As shown, in this embodiment, the clamping section 13 is parallel to the connecting section 12 , and both the clamping section 13 and the connecting section 12 are disposed in the slot 10 . That is to say: in this embodiment, the female housing 7 is not provided with an accommodating groove 11, the clamping section 13 and the connecting section 12 are both arranged in the slot 10, and the end of the connecting section 12 is welded to the first PCB board 1 superior.

[0057] Depend on Figure 7 , Figure 8 and Figure 9 As shown, in this embodiment, the first PCB board 1 and the second PCB board 2 also form a 90° angle. In this embodiment, the other structures of the female component 4 and the male component 5 are the same as those of the first embodiment, and will not be repeated here.

no. 3 example

[0059] The angle between the first PCB board 1 and the second PCB board 2 is 180°, as follows:

[0060] Depend on Figure 12 to Figure 15 As shown, in this embodiment, the first PCB board 1 and the second PCB board 2 are at 180°, specifically, the female header assembly 4 is arranged on the first PCB board 1, and the male header assembly 5 is arranged on the second PCB board 2 on. The second PCB board 2 can drive the male assembly 5 and the female assembly 4 on the first PCB 1 to achieve detachable electrical connection.

[0061] In this embodiment, the structures of the female component 4 and the male component 5 are the same as those of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com