A kind of Bacillus licheniformis and its application

A technology of Bacillus licheniformis and microbial strains, applied in bacteria, water/sludge/sewage treatment, biochemical equipment and methods, etc., can solve problems such as technical difficulties in biological treatment, and achieve the effect of strong temperature tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

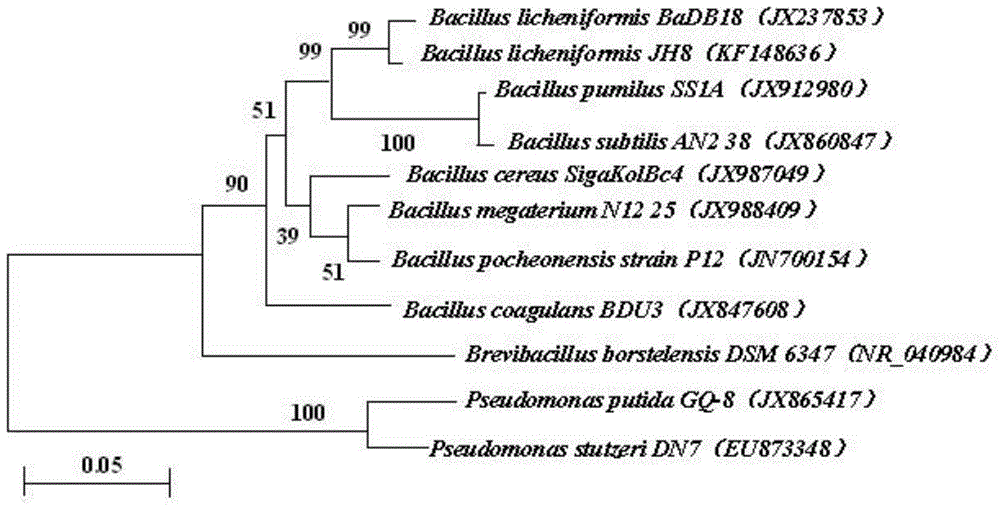

[0025] Isolation, purification and identification of strains

[0026] In this study, a piece of filler with biofilm was taken from the reactor of the bio-trickling filtration system established by South China University of Technology in Guangzhou Ruiming Power Co., Ltd., and put into a conical flask filled with 90mL sterilized denitrification culture solution and glass beads. , shake until the biofilm falls off, and remove the filler. Then put the triangular flask into an air shaker to fully shake the biofilm to break it up. After the crushed biofilm was shaken at an initial temperature of 30°C and shaken at 160r / min for 48 hours, 10% (volume ratio) of the bacterial solution was added to 100mL of fresh sterilized denitrification culture solution, and the temperature was raised to 35°C, shaking culture on a shaking table for 48 hours, inoculate 10% (volume ratio) of the bacteria solution into 100mL of fresh sterilized denitrification culture solution, and screen the dominant b...

Embodiment 2

[0030] Detection of denitrification performance of Bacillus licheniformis JH8

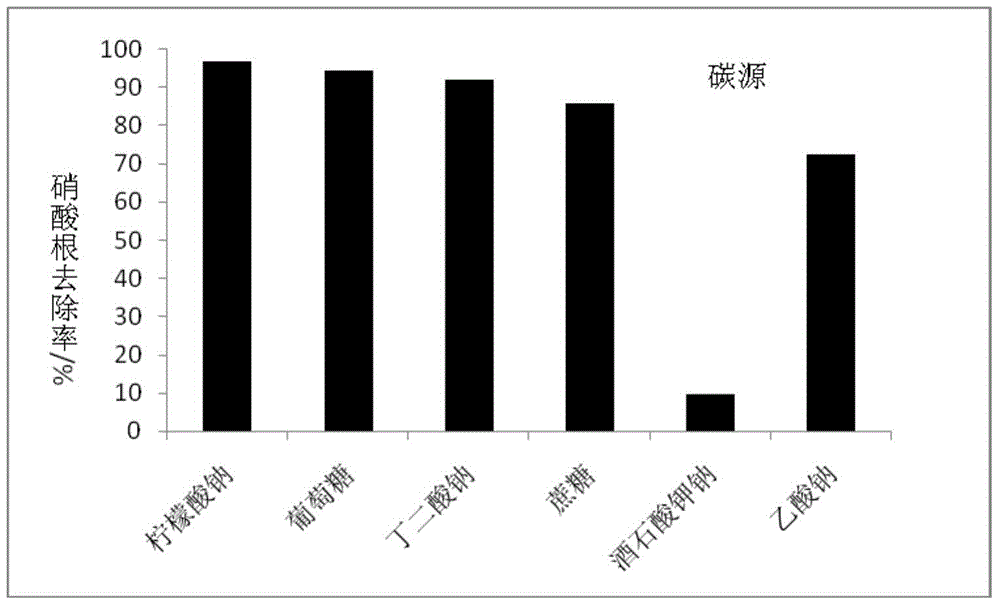

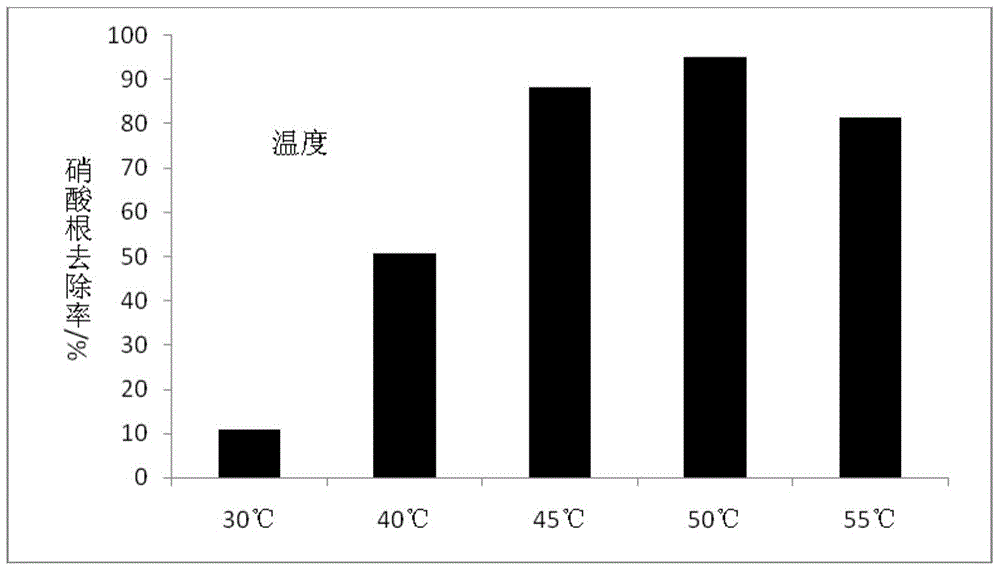

[0031] Denitrification performance of Bacillus licheniformis JH8 under different carbon sources

[0032] Investigate the strain's utilization of sodium succinate, sodium citrate, glucose, potassium sodium tartrate, sodium acetate and sucrose as carbon sources. The specific operation steps are as follows:

[0033] Inoculate 5mL of bacterial suspension into 95mL of denitrification medium. The composition of denitrification medium is as follows (g / L): KNO 3 1;Na 2 HPO 4 ·7H 2 O7.9; KH 2 PO 4 1.5; MgSO 4 ·7H 2 O0.1; trace element solution 2mL / L; pH7.0~7.5. Trace element solution composition (g / L): EDTA50.0; ZnSO 4 2.2; CaCl 2 5.5; MnCl 2 4H 2 O5.06; FeSO 4 ·7H 2 O5.0; (NH 4 ) 6 Mo 7 o 2 4H 2 O1.1; CuSO 4 ·5H 2 O1.57; CoCl 2 ·6H 2 O1. 61. Five kinds of carbon sources were added to make the C / N ratio 10, and the culture was shaken at 50°C and 200r / min.

[0034] Take 0h and 24h s...

Embodiment 3

[0046] Flue gas denitrification experiment of Bacillus licheniformis JH8

[0047] flue gas biological filtration denitrification system such as Image 6 As shown, the main part is a 2.5L bio-trickling filter tower 11, which is made of plexiglass and filled with honeycomb ceramic filler 12 (porosity 0.55, diameter 4-6mm). Use the dust-removed and desulfurized flue gas to adjust the air intake, then pass through the washing tower 1, and adjust the flue gas temperature at about 50°C through the washing tower 1, and spray the cooling water in the washing tower. After that, the flue gas will flow at a certain flow and velocity It enters the biological trickling filter tower from the bottom, and then discharges out after biological filtration, and finally completes the biological filtration and denitrification process of flue gas. A microbial activity regeneration system is built outside the filter tower. The water body between the filter tower and the microbial activity regenerati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com