Silicon-nanowire-based alkaline phosphatase fluorescent chemosensor, preparation method and application

A technology of chemical sensor and silicon nanowire, applied in the field of fluorescent chemical sensor, can solve the problem of unclear alkaline phosphatase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

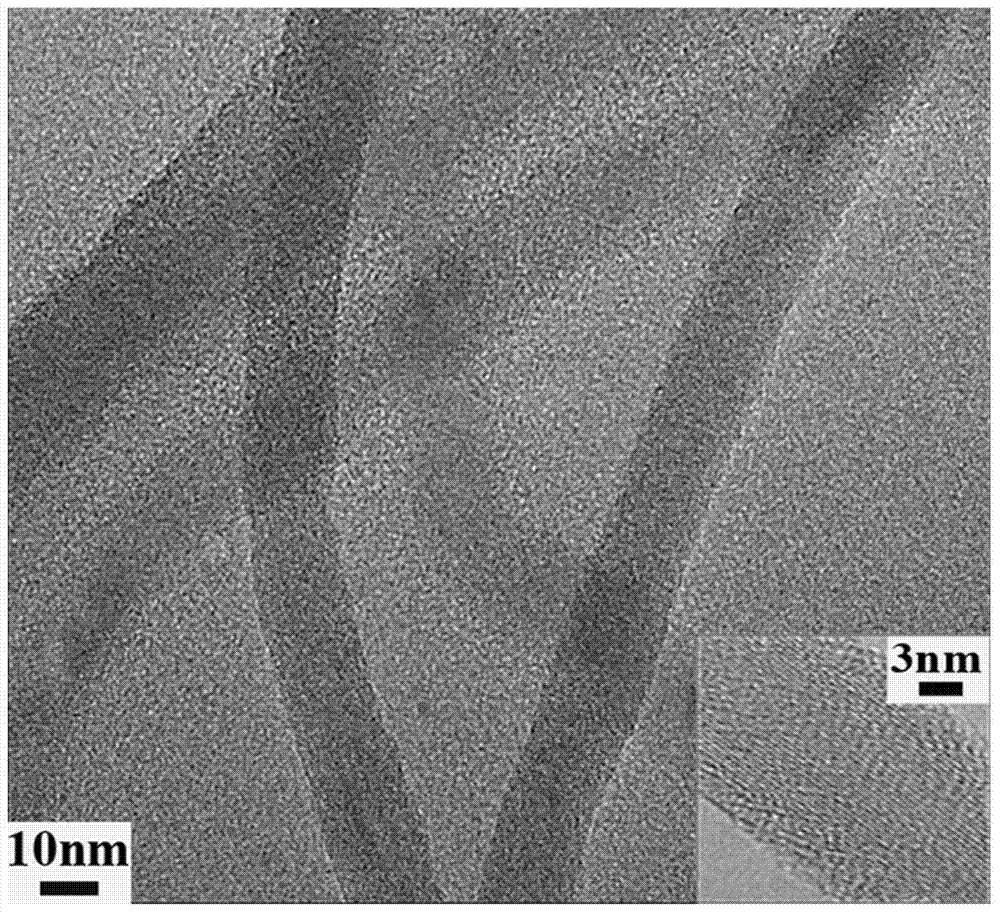

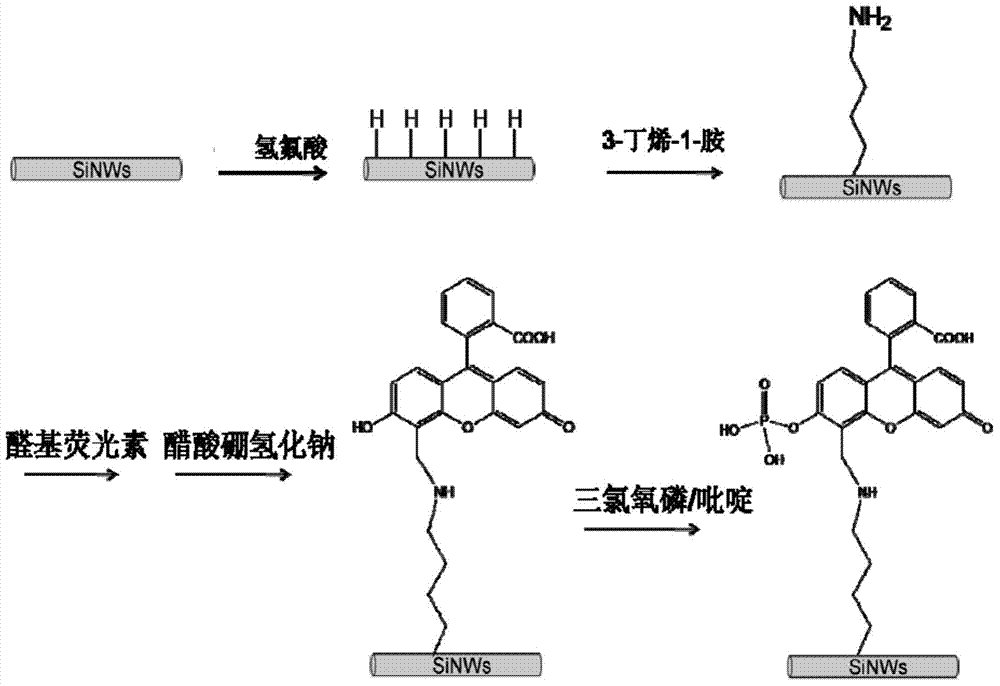

[0035] 1) At room temperature, put silicon monoxide into a porcelain boat after being ground by a mortar, and place the porcelain boat in the middle of the quartz tube of a horizontal tube furnace, and then vacuumize the system to 10 with a mechanical pump and a molecular pump. -3 Pa, then feed the mixed gas of argon (accounting for 95% of the volume of the mixed gas) and hydrogen (accounting for 5% of the volume of the mixed gas) at a flow rate of 50 sccm (mL / min), when the pressure is stabilized at 1000Pa, the system starts to heat up ;The system raised the temperature to 300°C at 10°C / min, and then raised to 800°C at 20°C / min. At this time, close the air valve and pump gate, keep it for 10 minutes, then continue to raise the temperature to 1350°C, and keep the temperature for 7 hours. The temperature of the furnace is naturally lowered; the product silicon nanowires are collected on both sides of the porcelain boat. The obtained silicon nanowires are single crystal silicon w...

Embodiment 2

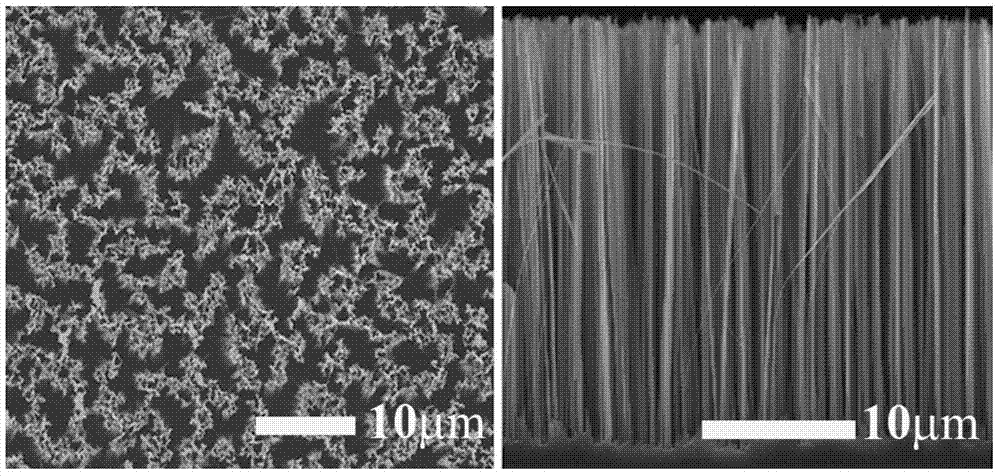

[0042] 1) Take n(100) silicon wafers of 2cm×1.0cm, and ultrasonically clean them with acetone, ethanol, and distilled water for 10 minutes; take out the cleaned silicon wafers and place them in AgNO with a concentration of 5mmol / L. 3 and 4.8mol / L HF mixed aqueous solution; after soaking for 5 minutes, take it out and put it into 10mL containing 4.8mol / L HF and 0.2mol / L H 2 o 2 In the mixed aqueous solution, the system was kept warm in a water bath at 50°C; after 15 minutes, the silicon chip was taken out and placed in a mixed solution containing 4.5mL concentrated hydrochloric acid (36% in mass concentration) and 1.5mL concentrated nitric acid (36% in mass concentration). Take out the silicon wafer after soaking for 0.5 hour, wash it with distilled water, and place it in a watch glass to dry naturally after rinsing to obtain a silicon nanowire array made of silicon nanowires, wherein the diameter of the silicon nanowires in the silicon nanowire array is 200-400nm, length 15-2...

Embodiment 3

[0050] 1) At room temperature, put silicon monoxide into a porcelain boat after being ground by a mortar, and place the porcelain boat in the middle of the quartz tube of a horizontal tube furnace, and then vacuumize the system to 10 with a mechanical pump and a molecular pump. -3 Pa, then feed the mixed gas of argon (accounting for 95% of the volume of the mixed gas) and hydrogen (accounting for 5% of the volume of the mixed gas) at a flow rate of 20 sccm (mL / min), when the pressure was stabilized at 700Pa, the system began to heat up ;The system raised the temperature to 300°C at 20°C / min, and then raised to 800°C at 10°C / min. At this time, the air valve and pump gate were closed, and the temperature continued to rise to 1350°C after keeping for 30 minutes, and the temperature was kept for 3 hours. The temperature of the furnace is naturally lowered; the product silicon nanowires are collected on both sides of the porcelain boat, and the obtained silicon nanowires are single ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com