A high temperature and corrosion resistant oil-immersed transformer

An oil-immersed transformer and corrosion-resistant technology, applied in the field of transformers, can solve the problems of high production cost and complicated production process, and achieve the effects of low cost, simple anti-corrosion process and good performance

Active Publication Date: 2016-06-01

JIANGSU HUASHENG ELECTRICAL CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The production process is complicated and the production cost is too high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1(E1

[0017]

Embodiment 2(E2

[0027]

Embodiment 3(E3

[0038]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

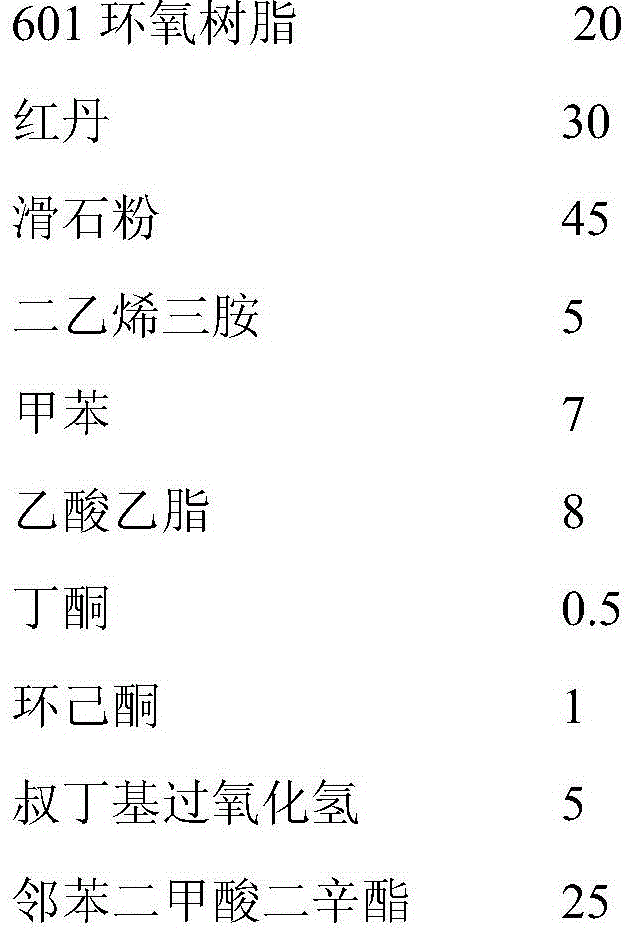

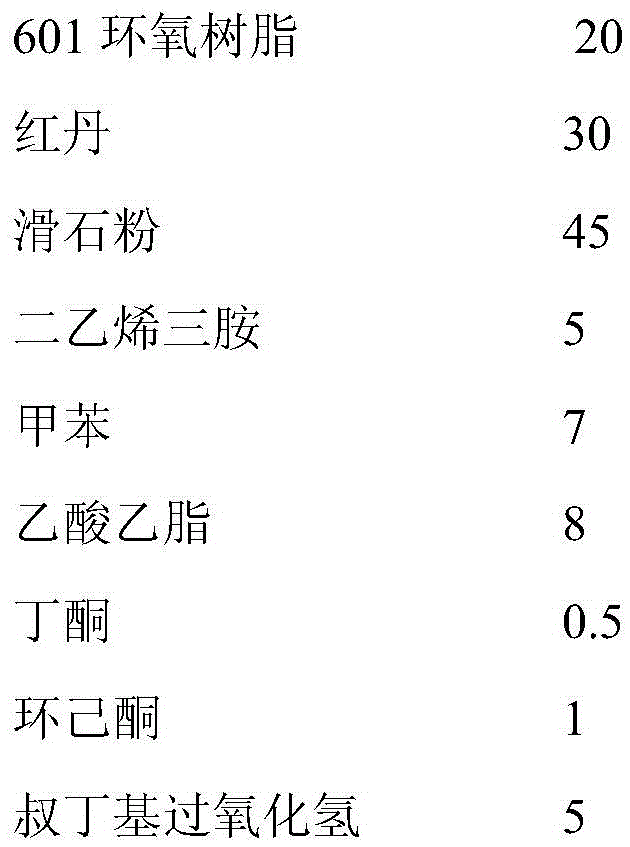

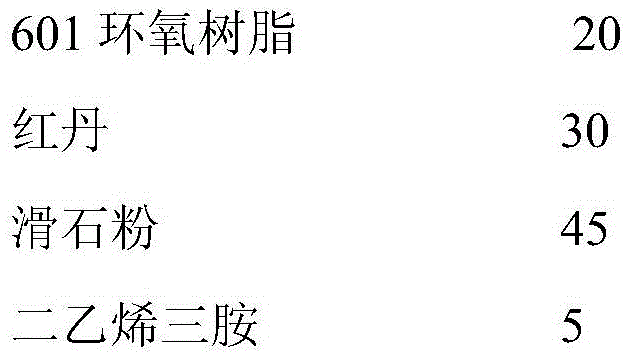

The invention relates to a high-temperature-resistant corrosion-resistant oil-immersed transformer which is prepared by coating an anticorrosive paint on a transformer shell. The anticorrosive paint comprises the following components in parts by weight: 20-30 parts of 601 epoxy resin, 30-40 parts of red lead, 45-54 parts of talcum powder, 5-6 parts of diethylenetriamine, 7-9 parts of methylbenzene, 8-10 parts of ethyl acetate, 0.5-1 part of butanone, 1-3 parts of cyclohexanone, 5-9 parts of tert-butyl hydroperoxide and 25-35 parts of dioctyl phthalate. The oil-immersed transformer has the advantages of fewer raw materials, go to the fields cost, simpler manufacturing technique and excellent corrosion resistance in high-temperature and high-corrosion environments.

Description

technical field [0001] The invention relates to a transformer, in particular to an oil-immersed transformer with anti-corrosion performance in a high-temperature and high-corrosion environment by coating anti-corrosion paint. Background technique [0002] In the production process of smelting and chemical industries, the emission of smoke and dust is relatively large, which has a serious corrosion effect on the metal shell of large transformers, especially the damage to the weak part of the transformer - the radiator. Corrosion has become a major hidden danger to the operation safety of large transformers, which affects the service life of transformers. It is economical and technically feasible to use paint protection for large transformers in operation. The operation is relatively simple and can be carried out by taking advantage of power failure opportunities. [0003] In the prior art, CN103509388 describes an epoxy resin transformer shell antirust paint, which consists ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D163/00C09D7/12C09D5/08H01F27/02

Inventor 张守国葛玉华许唯

Owner JIANGSU HUASHENG ELECTRICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com