Method for preparing tert-butyl carboxylate by using dual-modified SBA mesoporous molecular sieve catalyst

A technology of tert-butyl carboxylate and mesoporous molecular sieve, applied in the chemical industry, can solve the problems of high energy consumption for product separation and high investment in anti-corrosion equipment, and achieve the effects of high conversion rate, reduced energy consumption for separation and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

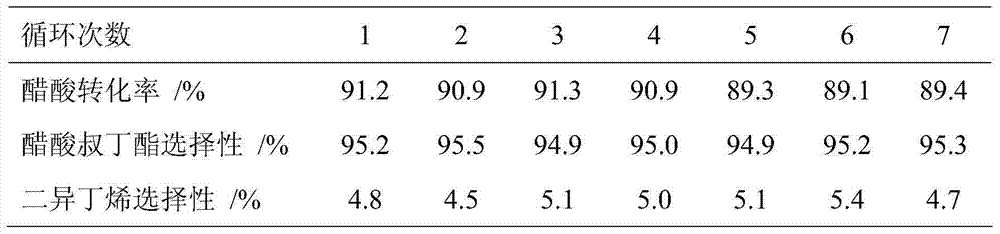

Examples

Embodiment 1

[0025] With 4g P123 (polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer, the molecular formula is PEO 20 PPOs 70 PEOs 20 , average molecular weight 5800) is dissolved in 97g distilled water at room temperature, then adding 23.50g mass concentration is 37% hydrochloric acid aqueous solution, adjusts H in the solution + The concentration is 1M, heat the solution to 40°C and stir to dissolve, add 0.01g aluminum isopropoxide after dissolution, then add 7.65g tetraethyl orthosilicate dropwise; continue to stir the obtained mixture at 40°C for 4h, add 2.16g of γ-mercaptopropyltrimethoxysilane and 24.33g of 30% H 2 o 2 Continue to stir the resulting mixture at 40°C for 24h, crystallize at 80°C in a hydrothermal synthesis kettle for 24h, filter the crystallized solid-liquid mixture, and wash the filter cake with deionized water until neutral; use ethanol Wash the mixed solution with hydrochloric acid for 48 hours under heating, stirring and reflux conditions to re...

Embodiment 2

[0027] Dissolve 4g of P123 in 97g of distilled water at room temperature, then add 23.50g of 37% aqueous hydrochloric acid to adjust the H + The concentration is 1M, heat the solution to 40°C and stir to dissolve, add 1.41g of stannous chloride after dissolution, then add 7.65g of tetraethyl orthosilicate dropwise; continue to stir the resulting mixture at 40°C for 4h, add 0.07g γ-mercaptopropyltrimethoxysilane and 0.81g30% H 2 o 2Continue to stir the resulting mixture at 40°C for 36h, crystallize at 90°C in a hydrothermal synthesis tank for 48h, filter the crystallized solid-liquid mixture, and wash the filter cake with deionized water until neutral; use ethanol The mixed solution with hydrochloric acid was washed under reflux conditions for 48 hours to remove the surfactant, and dried in vacuum at 70°C for 10 hours to obtain a mesoporous Sn-SBA- 15-SO 3 H.

Embodiment 3

[0029] Dissolve 4g of P123 in 97g of distilled water at room temperature, then add 23.50g of 37% aqueous hydrochloric acid to adjust the H + The concentration is 1M, heat the solution to 40°C and stir to dissolve, add 0.55g ferric chloride hexahydrate after dissolution, then add 7.65g tetraethyl orthosilicate dropwise; continue to stir the obtained mixture at 40°C for 4h , adding 0.72g of γ-mercaptopropyltrimethoxysilane and 8.11g of 30% H 2 o 2 Continue to stir the resulting mixture at 40°C for 20h, crystallize in a hydrothermal synthesis kettle at 100°C for 72h, filter the crystallized solid-liquid mixture, and wash the filter cake with deionized water until neutral; use ethanol The mixed solution with hydrochloric acid was washed under reflux conditions for 48 hours to remove the surfactant, and dried in vacuum at 80°C for 12 hours to obtain a mesoporous Fe-SBA- 15-SO 3 H.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com