Glue injection device for injection molding machine

A technology of injection device and injection molding machine, applied in the field of injection device, can solve the problems of poor product quality, material accumulation, high production cost, etc., achieve good calendering effect, reduce unit energy consumption and processing cost, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

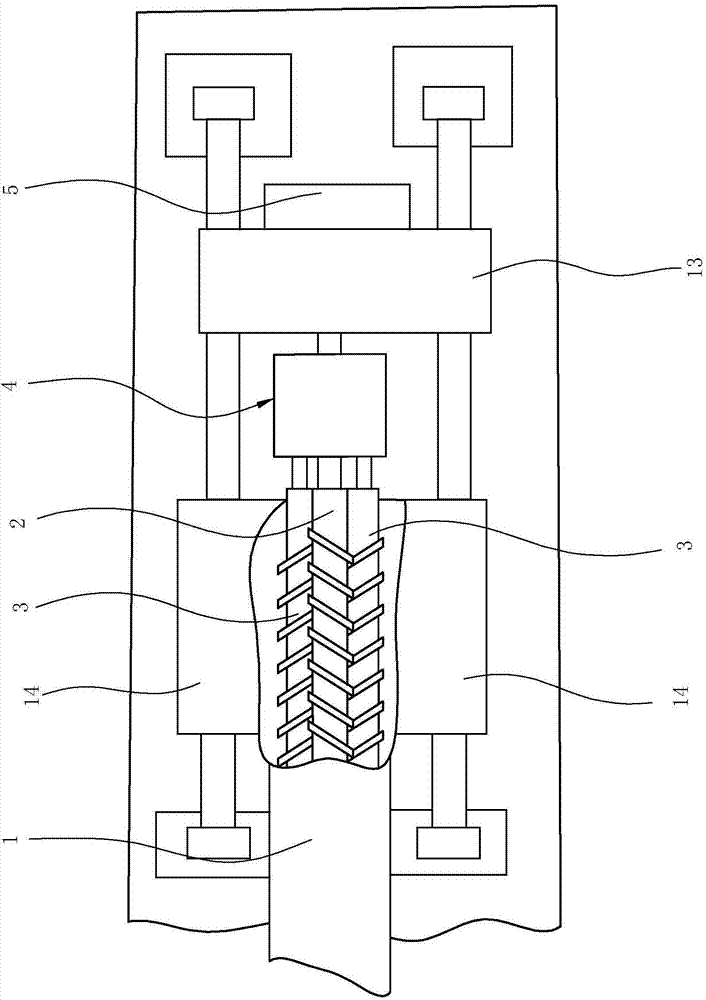

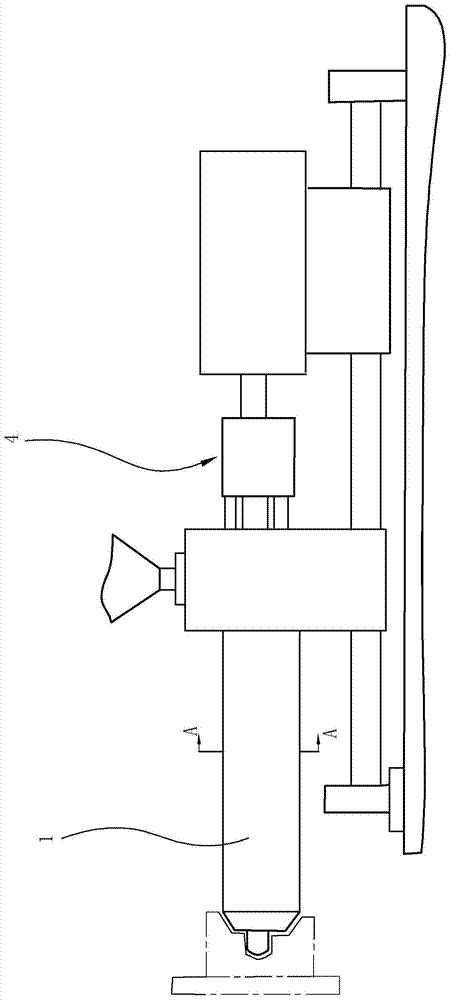

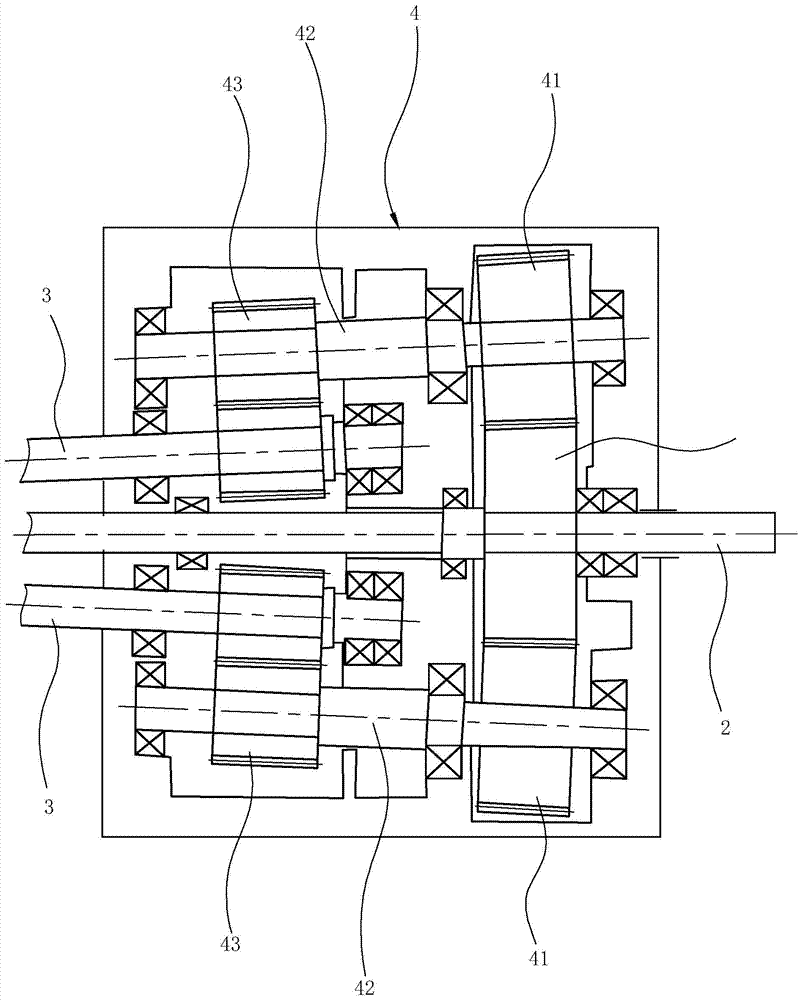

[0031] Such as Figures 1 to 12 As shown, the melt injection device for injection molding machine in this implementation includes plasticizing components, a power distribution mechanism 4, a hydraulic motor 5, and the like.

[0032] Among them, the plasticizing part includes a barrel 1 and a screw arranged in the barrel 1. There are three screws arranged in the barrel 1, and the three screws are arranged in a triangle. As another form of the arrangement of the three screws, it can also be three screws. They are arranged in parallel, and meanwhile, the inner wall of the barrel 1 is tangent to the outer trajectory formed by the rotation of the three screws.

[0033] There are three ways of contacting the above three screws. In the first way, each screw meshes with each other, which can improve the extrusion effect on the material; in the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com