Method for copper-molybdenum bulk concentrate floatation

A technology of copper-molybdenum mixed concentrate and copper-molybdenum, which is applied in flotation, solid separation, etc., can solve problems such as enlargement and over-grinding of copper minerals, and achieve the effect of reducing energy consumption and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

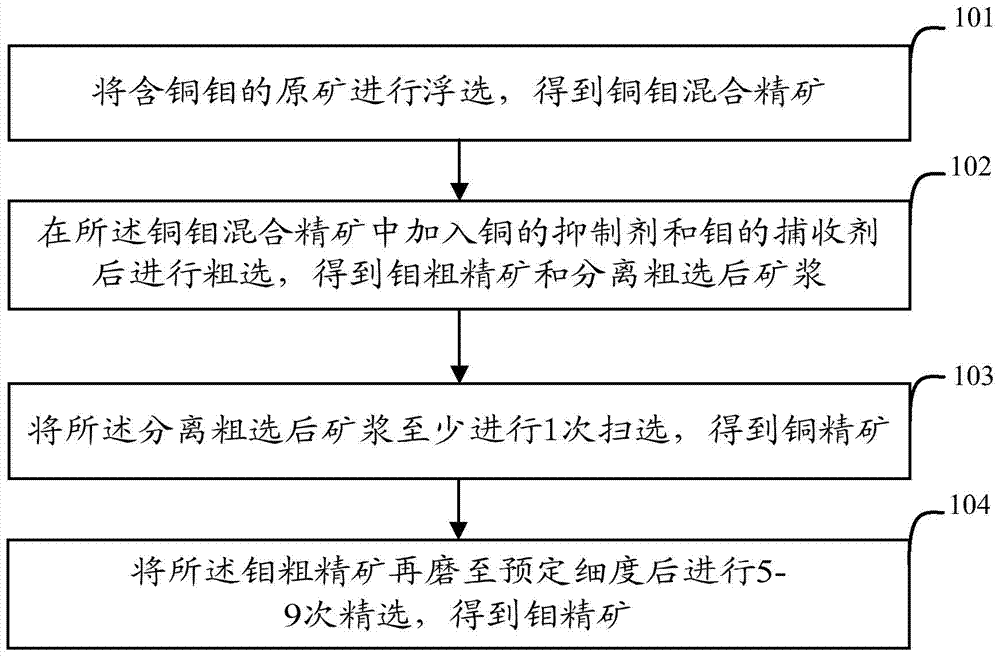

[0037] Please refer to figure 1 The embodiment of the present invention also provides a method for flotation of a copper-molybdenum mixed concentrate, which includes the following steps:

[0038] Step 101: Flotation of the raw ore containing copper and molybdenum to obtain a copper-molybdenum mixed concentrate;

[0039] In step 101, the flotation operation can be carried out in accordance with the conventional operation. During the flotation process, the raw ore containing copper and molybdenum is transported to a predetermined location through a belt and then the flotation operation is performed.

[0040] Step 102: After adding a copper inhibitor and a molybdenum collector to the copper-molybdenum mixed concentrate, roughing is performed to obtain a rough molybdenum concentrate and a slurry after separation and roughing;

[0041] Step 103: Sweep the slurry after the separation and coarse separation at least once to obtain a copper concentrate;

[0042] In this embodiment, the number o...

Embodiment 2

[0053] In this embodiment, the steps of the first embodiment are detailed and described in detail, which specifically includes the following steps:

[0054] A: Flotation of copper-molybdenum-containing raw ore is carried out to obtain a copper-molybdenum mixed concentrate; this step specifically includes the following operations:

[0055] 1. Grind the raw ore containing copper and molybdenum to obtain slurry;

[0056] Before the raw ore is subjected to primary selection, it needs to be ground (grinding to -200 mesh content 70.49%) in advance, the raw ore is ground into a slurry, and the obtained slurry enters the subsequent operation.

[0057] 2. After adding lime, butyl xanthate, and molybdenum collector to the slurry, a rough separation process is carried out to obtain a copper-molybdenum crude concentrate and a rough separation slurry;

[0058] In the rough separation process, butyl xanthate is used as a collector of copper and molybdenum, and No. 2 oil is used as a foaming agent, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com