Lithium ion secondary battery and method for manufacturing same

A secondary battery and manufacturing method technology, applied in the direction of secondary battery, electrolyte storage battery manufacturing, electrode manufacturing, etc., can solve the problems of shortening battery life, battery performance degradation, etc., and achieve the effect of improving charge-discharge cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] Examples and comparative examples related to the present invention will be described.

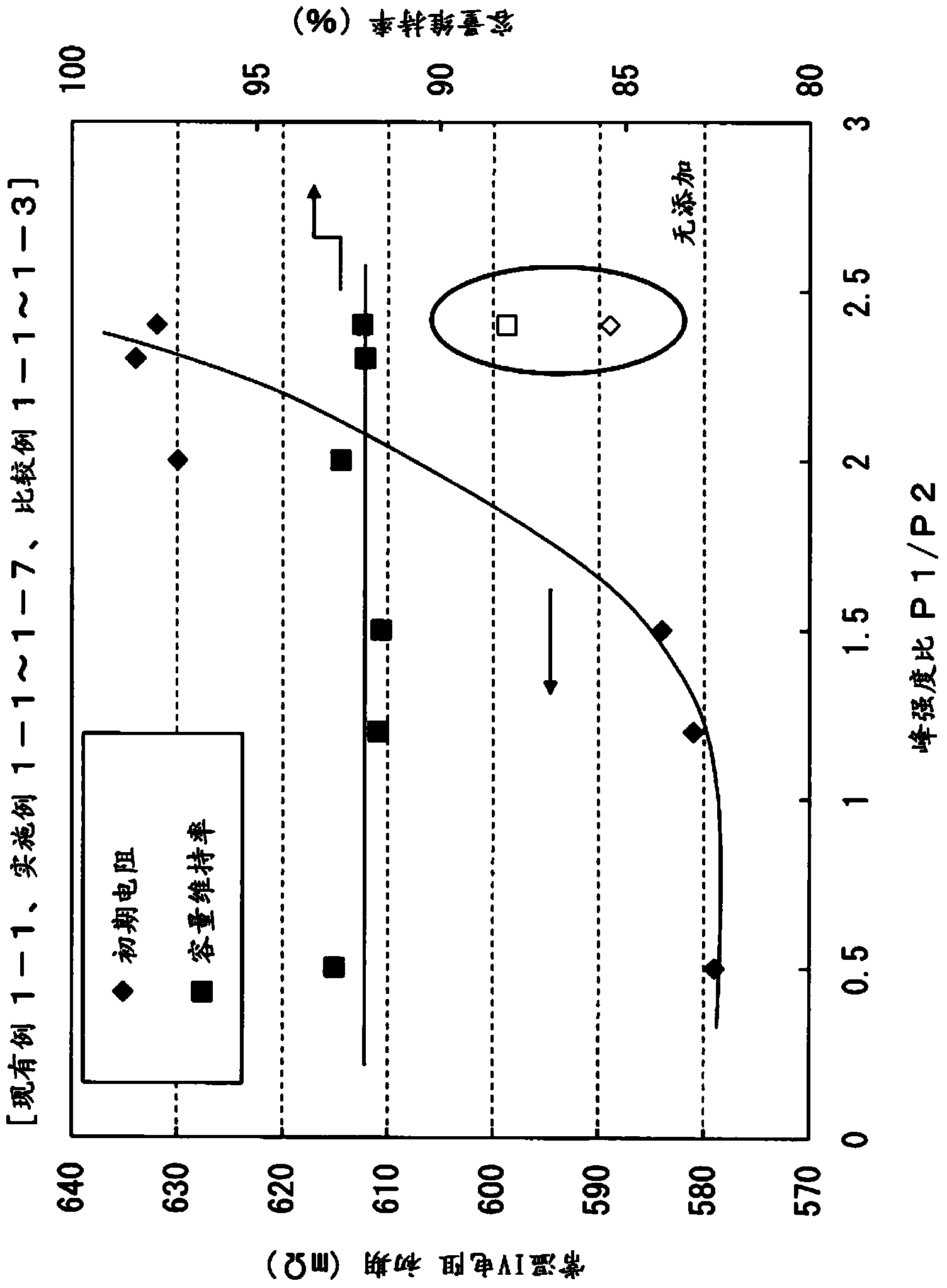

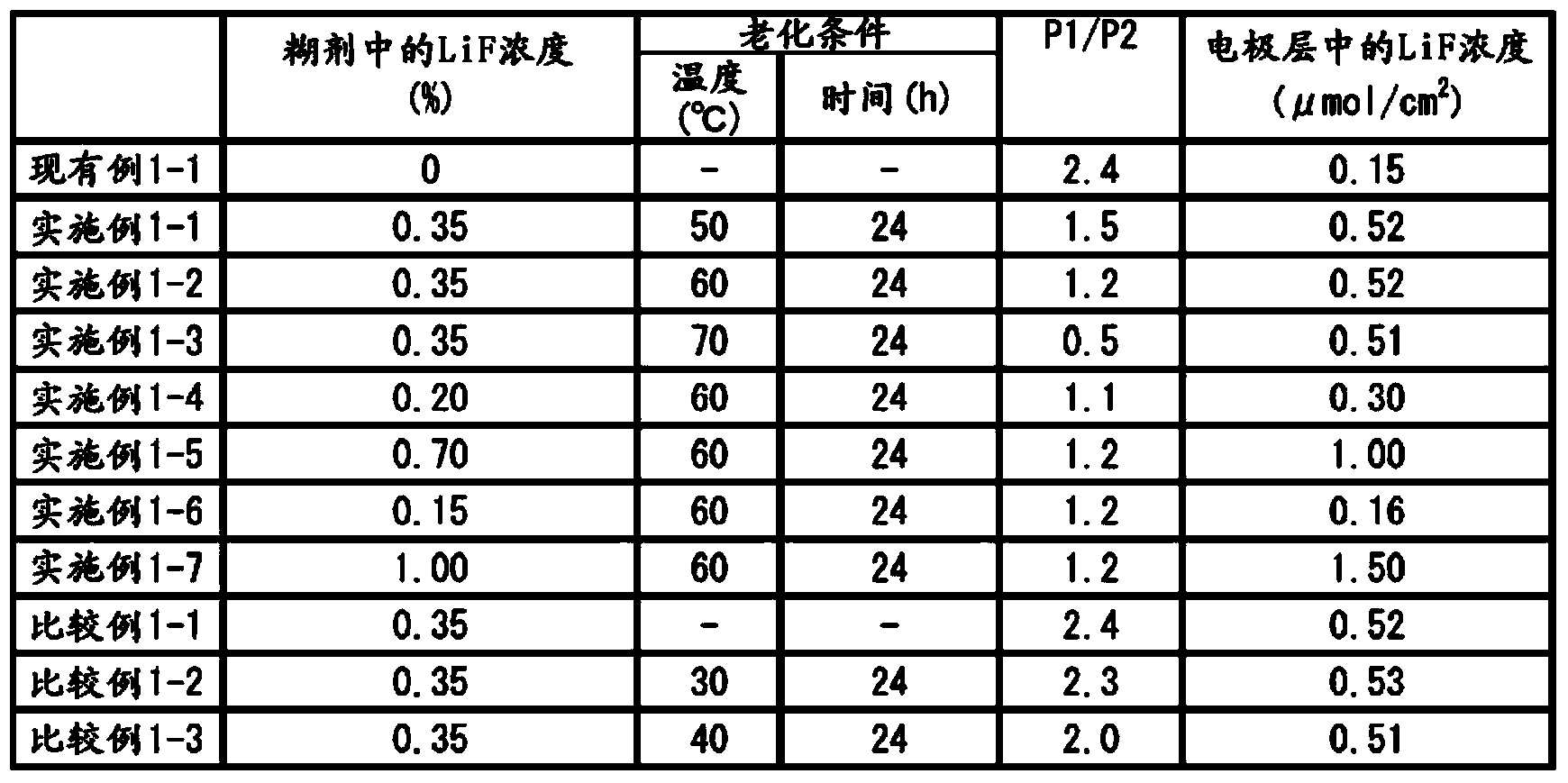

[0102] [Conventional Example 1-1, Examples 1-1 to 1-7, Comparative Examples 1-1 to 1-3]

[0103] In Conventional Example 1-1, Examples 1-1 to 1-7, and Comparative Examples 1-1 to 1-3, samples were prepared and evaluated by adding lithium fluoride to the negative electrode active material.

[0104]

[0105] Using the general formula LiMn 1 / 3 co 1 / 3 Ni 1 / 3 o 2 The ternary lithium composite oxide shown is used as the positive electrode active material. The specific surface area of the positive electrode active material is 1.3m 2 / g.

[0106] In each example, N-methyl-2-pyrrolidone was used as a dispersant, and the above positive electrode active material, acetylene black as a conductive agent, and PVDF as a binder were mixed to obtain a paste for electrode layer formation.

[0107] In each example, the mass ratio of the positive electrode active material, the conductive agent...

Embodiment 2-1~2-7

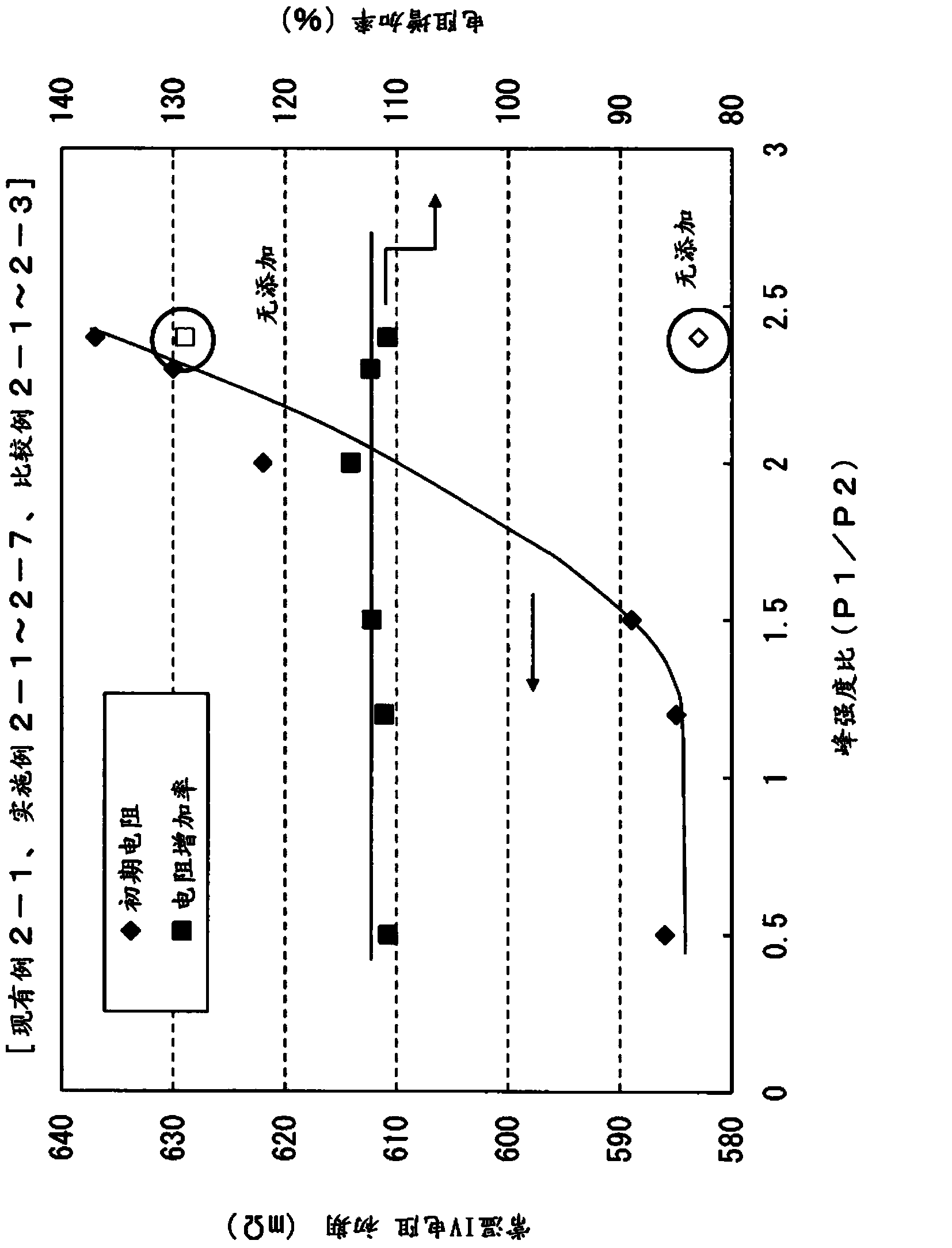

[0152] [Conventional Example 2-1, Examples 2-1 to 2-7, Comparative Examples 2-1 to 2-3]

[0153] In Conventional Example 2-1, Examples 2-1 to 2-7, and Comparative Examples 2-1 to 2-3, samples were produced and evaluated for the addition of lithium fluoride to the positive electrode active material.

[0154]

[0155] Using the general formula LiMn 1 / 3 co 1 / 3 Ni 1 / 3 o 2 The ternary lithium composite oxide shown is used as the positive electrode active material. The specific surface area of the positive electrode active material is 1.3m 2 / g.

[0156]In Examples 2-1 to 2-7 and Comparative Examples 2-1 to 2-3, N-methyl-2-pyrrolidone was used as a dispersant, and the above-mentioned positive electrode active material, lithium fluoride, and acetylene as a conductive agent were mixed. black, and PVDF as a binder to obtain a paste for electrode layer formation.

[0157] Table 3 shows the lithium fluoride concentration (mass %) in the solid content of the paste for electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com