Large-face pumping slab laser module capable of efficient cooling

A laser module and large surface pump technology, applied in lasers, laser parts, phonon exciters, etc., can solve problems such as affecting the beam quality of the output beam, reducing thermal gradients, etc., achieving low loss, reducing thermal gradients, The effect of high laser output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

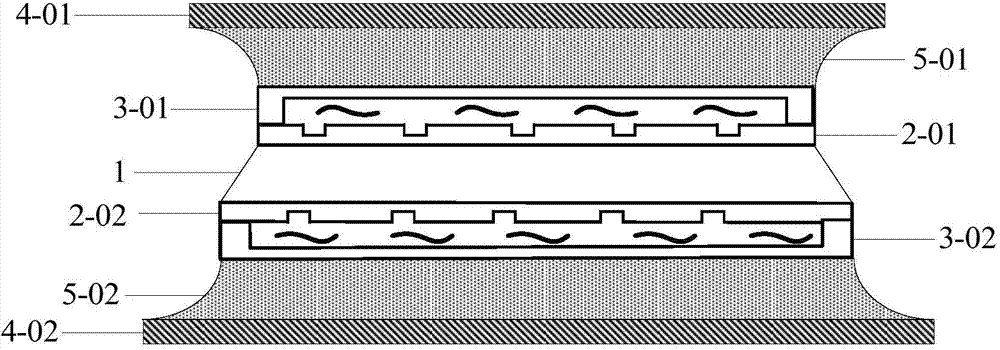

[0042] figure 1 Shown: a large-area pumped slab laser module with high efficiency cooling, including: slab laser medium 1, first transparent heat sink 2-01, second transparent heat sink 2-02, first transparent cooling device 3- 01. The second transparent cooling device 3-02, the first semiconductor pumping source 4-01, the second semiconductor pumping source 4-02, the first pumping beam 5-01 and the second pumping beam 5-02.

[0043] The slab laser medium 1 uses Nd:YAG crystal, the doping concentration of Nd ions is 0.6%, and its size is a parallelepiped slab of 80mm×30mm×3mm. The two upper and lower planes of the slab are parallel, and the two left and right end surfaces are also parallel. and form Brewster's angle with the main plane;

[0044] The semiconductor pump source 4 includes 2 pumping arrays, each array is composed of 60 semiconductor laser (LD) arrays, arranged in 20 rows and 3 columns, each LD output power is 20W, and the wavelength is 808nm; the semiconductor pu...

Embodiment 2

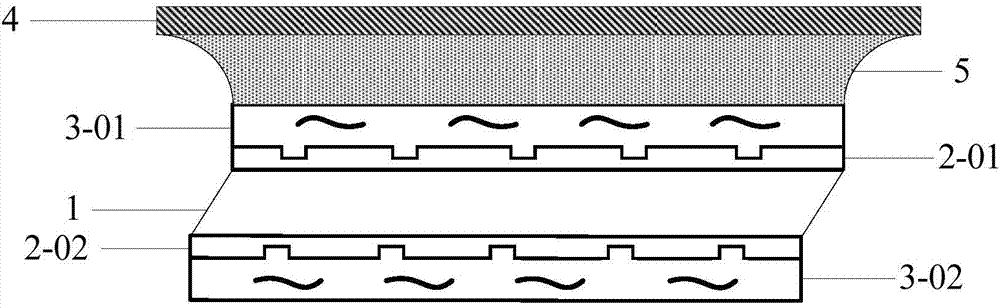

[0047] figure 2 Shown: a large-area pumped slab laser module with high efficiency cooling, including: slab laser medium 1, first transparent heat sink 2-01, second transparent heat sink 2-02, first transparent cooling device 3- 01. The second transparent cooling device 3-02, the semiconductor pumping source 4 and the pumping beam 5.

[0048] It can be seen from the figure that this embodiment has made technical improvements based on the efficiently cooled large-area pumped slab laser module in embodiment 1. Compared with the embodiment 1, the structural improvement of this embodiment is that the pumping method is changed from double-sided large-area pumping to single-side large-area pumping to obtain a simpler structure. The semiconductor pump source 4 includes a pumping array, which is composed of 60 semiconductor laser (LD) arrays, arranged in 20 rows and 3 columns, each LD has an output power of 20W and a wavelength of 808nm. Compared with bilateral symmetrical pumps, un...

Embodiment 3

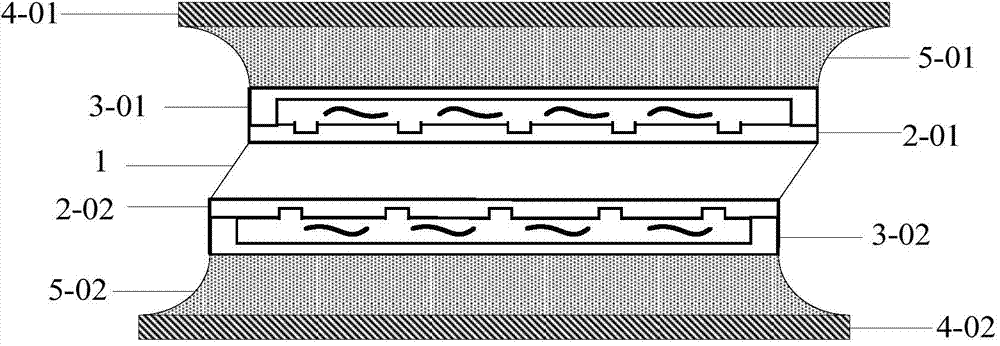

[0050] image 3 Shown: a large-area pumped slab laser module with high efficiency cooling, including: slab laser medium 1, first transparent heat sink 2-01, second transparent heat sink 2-02, first transparent cooling device 3- 01. The second transparent cooling device 3-02, the first semiconductor pumping source 4-01, the second semiconductor pumping source 4-02, the first pumping beam 5-01 and the second pumping beam 5-02.

[0051] It can be seen from the figure that this embodiment has made technical improvements based on the efficiently cooled large-area pumped slab laser module in embodiment 1. The difference from the structure of Embodiment 1 is that the longitudinal section of the slab laser medium 1 is changed from a parallelogram slab structure cut at Brewster’s angle to an isosceles trapezoidal slab structure cut at Brewster’s angle, for obtaining different orientations. laser output. The dimensions of the upper and lower sides of the isosceles trapezoid are 80mm a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com