Online oil liquid abrasive particle monitoring device and measuring method

A monitoring device and technology of oil abrasive particles, applied in the direction of material resistance, etc., can solve the problems that cannot meet the needs of abrasive particle technology, the abrasive particle detection process is not suitable, the imaging speed is slow and online detection cannot be realized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

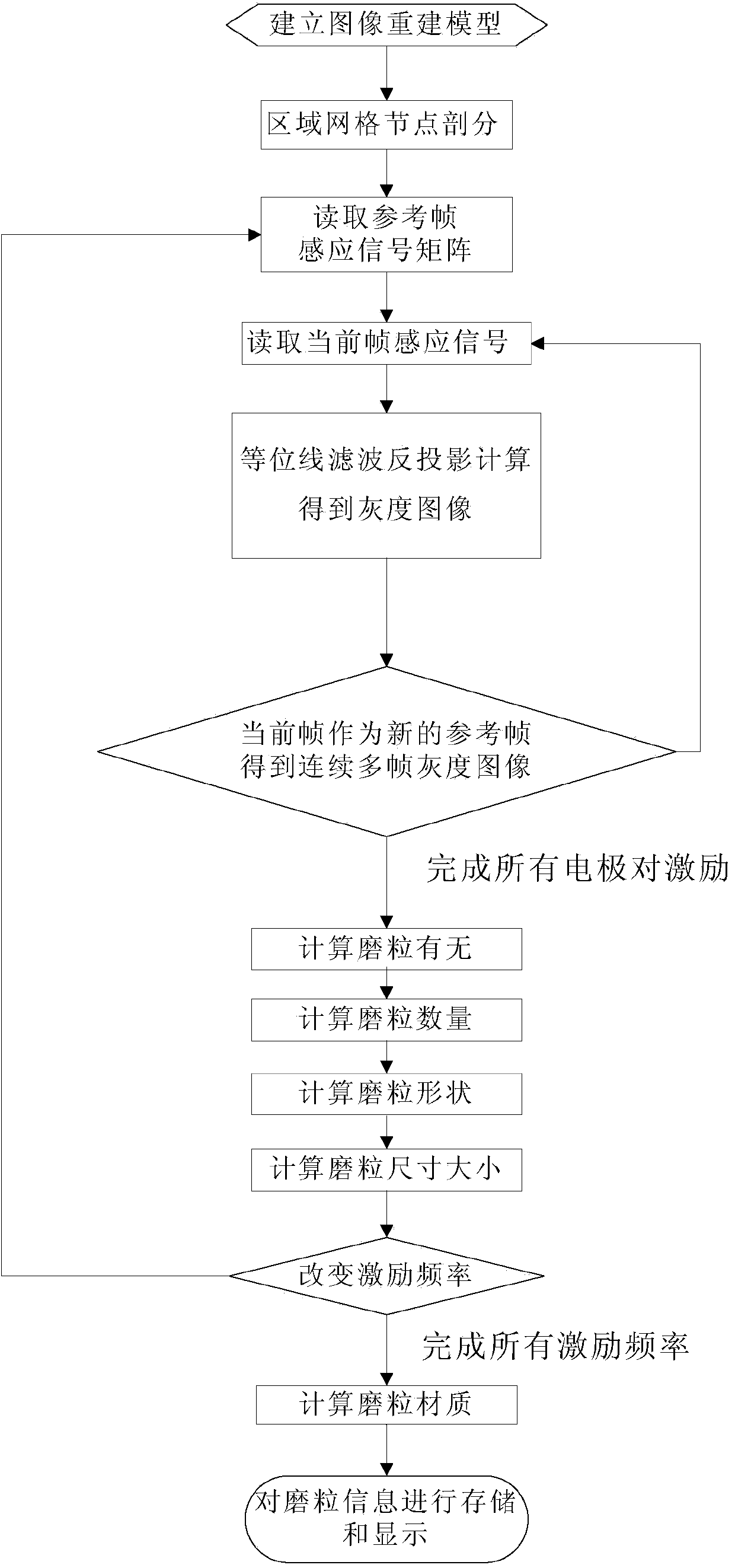

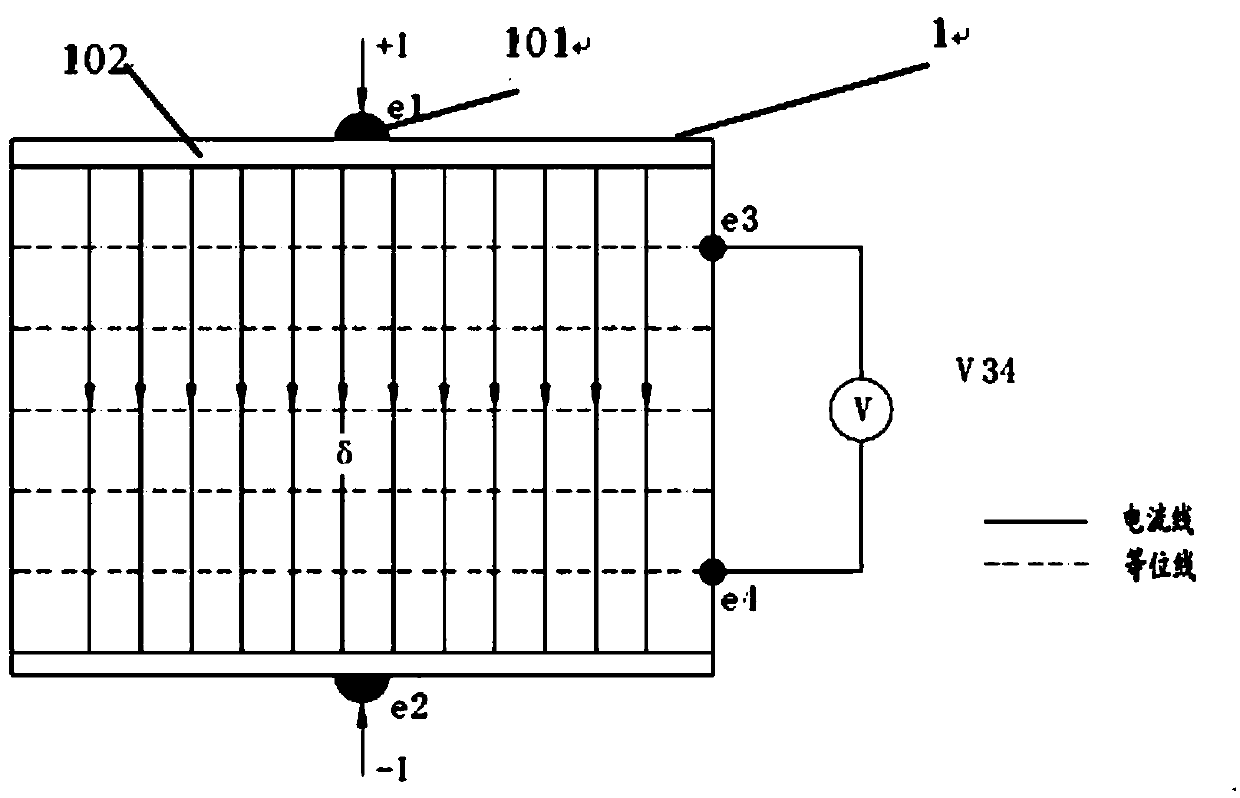

[0066] Such as figure 1 As shown, the online oil wear particle monitoring device in the embodiment of the present invention includes: an online multi-electrode tomography wear particle sensor 1, an excitation signal source circuit 2, a signal detection filter circuit 3, an analog-to-digital conversion circuit 4, a computer 5, Display 6 and keyboard 7.

[0067] Among them, the online multi-electrode tomography wear particle sensor 1 is a composite array sensor of the electrical tomography system that can be connected to the oil pipeline online, and is a sensor for the purpose of realizing impedance imaging. It consists of a certain number of electrodes 101 constitute. The plurality of electrodes 101 are realized by thick resist lithography technology (thick resist lithography t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com