A method for installing a wine glass-shaped iron tower of an UHV transmission line

A technology of transmission lines and installation methods, applied in towers, building types, buildings, etc., can solve problems such as the difficulty of hoisting in place with ordinary poles, reduce the probability of personnel and mechanical injuries, achieve environmental protection, and have the effect of large lifting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

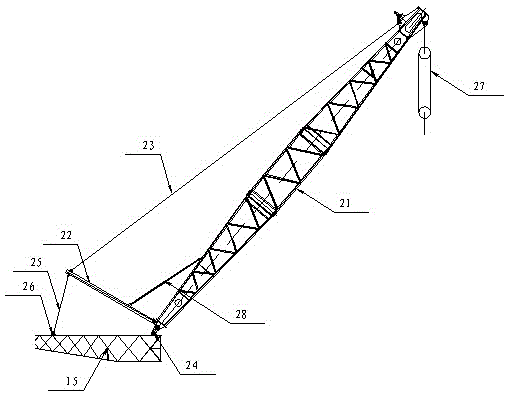

[0045] Such asfigure 1 Shown, the installation method of a kind of UHV transmission line wine cup type iron tower of the present invention, it comprises the following steps:

[0046] (1) Preparation before construction: clean up the construction site of the iron tower, arrange the construction site and prepare the tower foundation, transport the tower materials required for the installation of the iron tower, conduct quality inspection and clean up the materials;

[0047] (2) Assemble the main pole and erect the main pole;

[0048] (3) Assemble and erect the tower legs on the tower base;

[0049] (4) Place the main material pieces and tower pieces for assembling the iron tower body on the ground, lift the main pole, and hoist and assemble the tower body piece by piece;

[0050] (5) Lift the main pole to hoist the lower crank arm and upper crank arm of the iron tower;

[0051] (6) Hoisting the middle horizontal tank;

[0052] (7) Assemble the auxiliary pole on the ground and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com