Outer wall strengthening rivet and outer wall strengthening method

An external wall and rivet technology, applied in building maintenance, construction, building structure and other directions, can solve problems such as large economic losses, falling off, affecting project quality, etc., to save maintenance costs and achieve the effect of reinforcement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

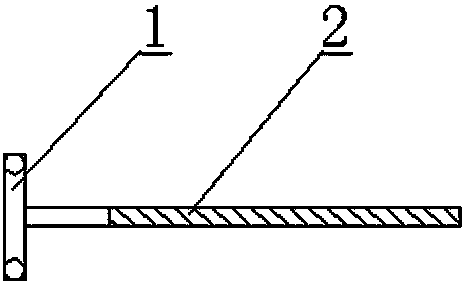

[0030] Example 1: Reinforcement of filled walls

[0031] 1. Outside the separated insulation layer 3, use a portable cutting machine to cut along the joints of the pasted tiles into an "I" shape, and the depth shall not damage the fiber mesh of the inner layer of the tile.

[0032] 2. After the above process is completed, use a φ8 extended drill to penetrate the wall, and then use a portable cutting machine to cut an inner groove with a depth of 1cm, a width of 2cm, and a length of 6-8cm, and then insert the long rivet 3 along the "work ” font cutout, and use supporting tool 4 to tighten it after passing through the wall. Then put into two φ 6 round steel heads 5 of about 3cm long in the inner groove, and the round steel heads 5 and the tensioned long rivets 3 are welded together by electric welding. At this time, the reinforcement task is completed.

[0033] 3. Remove the supporting tool 4 and use it again, cut off the excess part of the exposed wall with a cutting machine,...

Embodiment 2

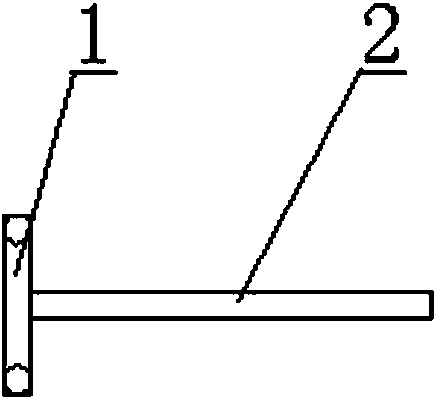

[0036] Example 2: Reinforcement of concrete walls

[0037] 1. Outside the separated insulation layer 3, use a portable cutting machine to cut along the joints of the pasted tiles into an "I" shape, and the depth shall not damage the fiber mesh of the inner layer of the tile.

[0038] 2. Use a φ8 extended drill bit to drill holes along the tile seam of the outer wall to the concrete wall 6. Clean the dust in the hole, implant the chemical anchor bolt 7 of φ8, and after it is completely solidified (reaching the standard strength), use the supporting tool 4 to reinforce and tighten it, and the separation wall will be completely reset. Use the same method to implant short rivets 8 around the periphery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com