Small and medium-sized steel bridge deck pavement system and implementation method

A bridge deck paving and steel bridge deck technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problem of uneven thickness, does not fundamentally solve the problem of steel bridge deck paving, and is not suitable for self-flowing pouring type. Asphalt mixture and other problems, to achieve the effect of good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention is further described and examples are given below.

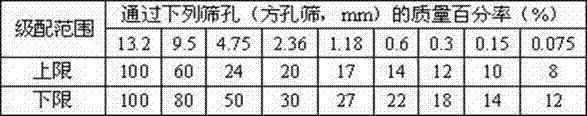

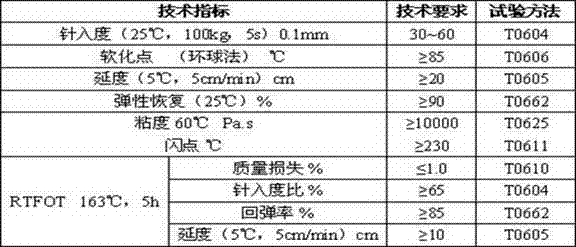

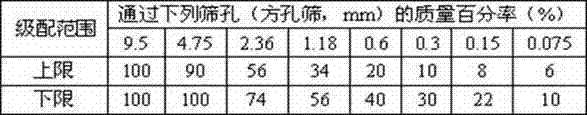

[0029] The technical scheme of the present invention is achieved in this way, a bridge deck pavement system for small and medium-sized steel bridge decks, characterized in that: the pavement system is respectively provided with a modified epoxy resin waterproof layer, a bonding layer, waterproof modified asphalt sand layer, thermal sprayed SBS modified asphalt layer and high viscosity modified asphalt layer. Among them, the high-viscosity modified asphalt layer adopts high-viscosity modified asphalt SMA-10. Their thickness or amount is modified epoxy resin waterproof layer 3kg / m 2 , Adhesive layer particles 0.8~1.0kg / m 2 , particle diameter is 1mm, 5~10mm crushed stone 1.8kg / m 2 , 3cm modified waterproof asphalt sand, thermal spray SBS modified asphalt 0.2~0.4kg / m 2 , 4cm high viscosity modified asphalt SMA-10.

[0030] A method for implementing a bridge deck pavement system for small and medium-siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com