Method for producing high-purity vanadium pentoxide by using vanadium-containing waste residues

A high-purity vanadium pentoxide technology, which is applied in the field of producing high-purity vanadium pentoxide, can solve the problems of low vanadium recovery rate, high water consumption for washing and filtering calcium slag, and low purity of vanadium pentoxide, so as to improve the purity , Increase added value, enhance the effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

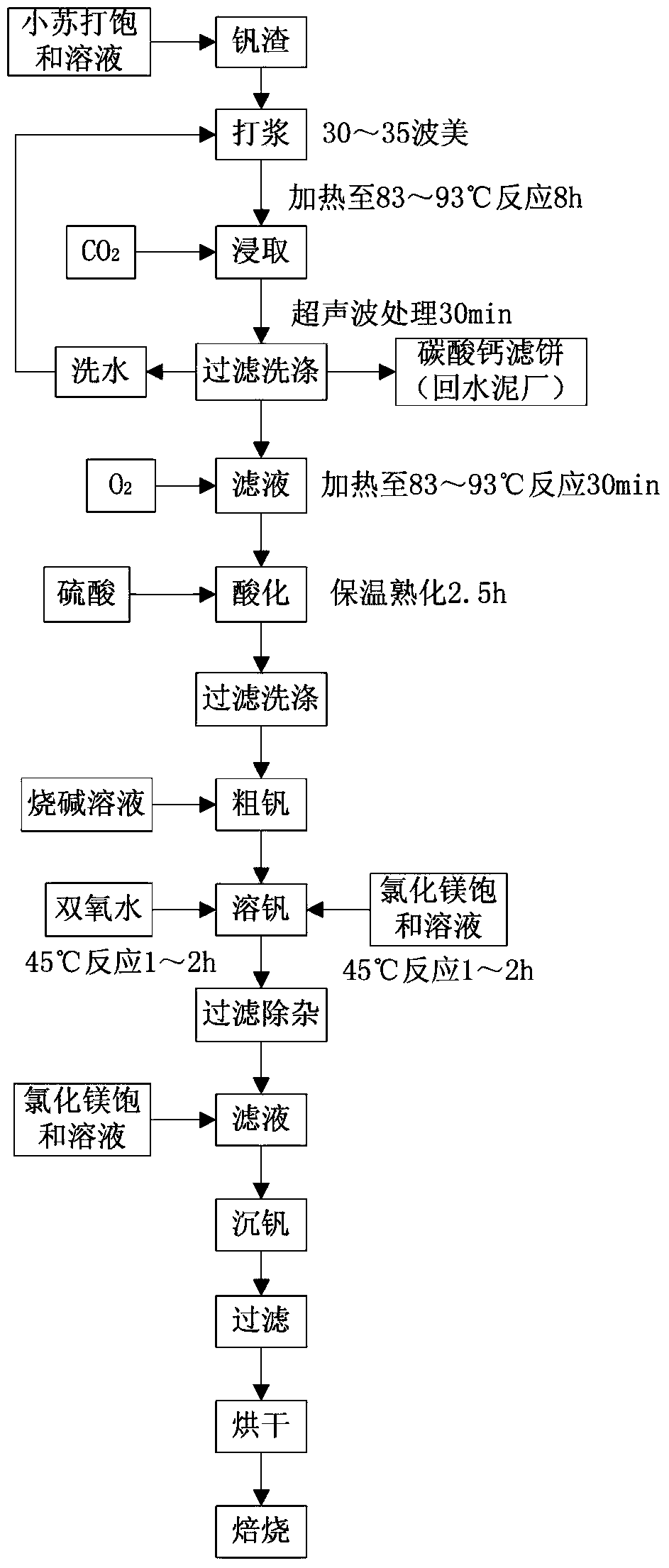

Method used

Image

Examples

Embodiment 1

[0028] a) Weighing 150kg of vanadium-containing waste residue and placing it in a reactor, adding 160L of tap water to beating to 35Be, then adding a saturated solution of baking soda, the pH of the seasoning slurry is 9.1, and the temperature is raised to 93°C;

[0029] b), into the CO 2 Gas stirring reaction 8h after ultrasonic treatment 30min, suction filtration and collection of filtrate, the obtained calcium carbonate filter cake is washed with 300L temperature of 80 ℃ tap water, the vanadium content in the calcium slag after washing is 0.026%, and the washing water is returned to the previous step for slurrying. The vanadium recovery rate is 92.43%;

[0030] c), the resulting solution is passed through O at 93°C 2 For 30 minutes, oxidize the low-valent vanadium present in the solution to pentavalent vanadium to increase the yield of vanadium, and then add concentrated sulfuric acid to adjust the pH to 2 for acidification;

[0031] d), after heat preservation and stirri...

Embodiment 2

[0036] a) Weigh 150kg of vanadium-containing waste residue and place it in a reaction kettle, add 150L of tap water to it and beat to 33Be, then add a saturated solution of baking soda, the pH of the seasoning slurry is 9.3, and the temperature is raised to 94°C;

[0037] b), into the CO 2 Gas stirring reaction 8h after ultrasonic treatment for 30min, suction filtration and collection of filtrate, the obtained calcium carbonate filter cake is washed with 350L temperature of 80 ℃ tap water, the vanadium content in the calcium slag after washing is 0.019%, and the washing water is returned to the previous step for slurrying. Vanadium recovery rate is 94.69%;

[0038] c), the resulting solution is passed through O at 94°C 2 For 30 minutes, oxidize the low-valent vanadium present in the solution to pentavalent vanadium to increase the yield of vanadium, and then add concentrated sulfuric acid to adjust the pH to 1.7 for acidification;

[0039] d), after heat preservation and sti...

Embodiment 3

[0044] a) Weighing 150kg of vanadium-containing waste residue and placing it in a reactor, adding 156L of tap water to beating to 34Be, then adding a saturated solution of baking soda, the pH of the seasoning slurry is 9.2, and the temperature is raised to 93°C;

[0045] b), into the CO 2 Gas stirring reaction 8h after ultrasonic treatment 30min, suction filtration and collection of filtrate, the obtained calcium carbonate filter cake is washed with 330L temperature of 80 ℃ tap water, the vanadium content in the calcium slag after washing is 0.027%, and the washing water is returned to the previous step for slurrying. Vanadium recovery rate is 95.73%;

[0046] c), the resulting solution is passed through O at 93°C 2 For 30 minutes, oxidize the low-valent vanadium present in the solution to pentavalent vanadium to increase the yield of vanadium, and then add concentrated sulfuric acid to adjust the pH to 1.9 for acidification;

[0047] d), after heat preservation and stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com