Cross-linkable and re-dispersible polymer powder with high adhesive property

A technology of redispersing polymers and high adhesion, which is applied in the field of cross-linkable redispersible polymer powders, can solve the problems of decreased bonding ability of polymer components, affecting the mechanical strength of coating films, etc., and can improve the water phase Effects of redispersion performance and, increased electrostatic and steric hindrance, excellent self-bonding and substrate adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

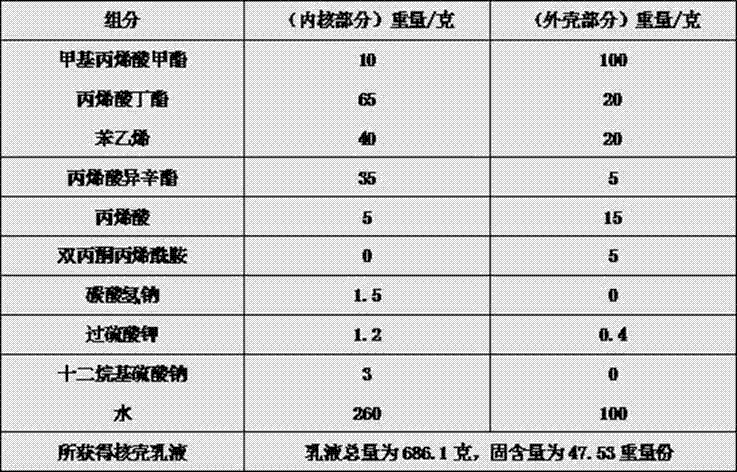

Image

Examples

Embodiment 1

[0038] A cross-linkable redispersible polymer powder with high bonding performance, including polymer and water-soluble polymer protective colloid; wherein, the polymer is composed of the following raw materials in parts by weight: 5 parts by weight of A monoethylenically unsaturated monomer unit with a carboxyl group or a ketone carbonyl group, 10 parts by weight of a monoethylenically unsaturated monomer unit with a carboxyl group or a hydroxyl group, and 70 parts by weight of a non-branched monomer unit with 1-15 carbon atoms or branched alcohol (meth)acrylic acid alkyl ester and unsaturated monomer unit composed of vinyl aromatic compound; the weight of water-soluble polymer protective colloid is 8% of the total weight of the polymer.

[0039] Wherein, the monoethylenically unsaturated monomer unit with methylol or ketone carbonyl is one of N-methylolacrylamide and diacetone acrylamide or two of them in any proportion. In the embodiment 1 is N-methylolacrylamide;

[0040]...

Embodiment 2

[0045] A cross-linkable redispersible polymer powder with high bonding performance, including polymer and water-soluble polymer protective colloid; wherein, the polymer is composed of the following raw materials in parts by weight: 10 parts by weight of A monoethylenically unsaturated monomer unit with a carboxyl group or a ketone carbonyl group, 15 parts by weight of a monoethylenically unsaturated monomer unit with a carboxyl group or a hydroxyl group, and 75 parts by weight of a non-branched monomer unit with 1-15 carbon atoms Or branched alcohol (meth)acrylic acid alkyl ester and vinyl aromatic compound composed of unsaturated monomer units; the weight of water-soluble polymer protective colloid is 1% of the total weight of the polymer.

[0046] Wherein, the monoethylenically unsaturated monomer unit with methylol or ketone carbonyl is one of N-methylolacrylamide and diacetone acrylamide or two of them in any proportion. In the embodiment 2 is diacetone acrylamide;

[004...

Embodiment 3

[0052] A cross-linkable redispersible polymer powder with high bonding performance, including polymer and water-soluble polymer protective colloid; wherein, the polymer is composed of the following raw materials in parts by weight: 8 parts by weight of A monoethylenically unsaturated monomer unit with a carboxyl group or a ketone carbonyl group, 5 parts by weight of a monoethylenically unsaturated monomer unit with a carboxyl group or a hydroxyl group, and 85 parts by weight of a non-branched monomer unit with 1-15 carbon atoms or branched alcohol (meth)acrylic acid alkyl ester and unsaturated monomer unit composed of vinyl aromatic compound; the weight of water-soluble polymer protective colloid is 6% of the total weight of the polymer.

[0053] Wherein, the monoethylenically unsaturated monomer unit with methylol or ketone carbonyl is one of N-methylolacrylamide and diacetone acrylamide or two of them in any proportion. In the embodiment 2 is N-methylolacrylamide;

[0054] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com