Method for preparing glycine zinc chelate

A technology of zinc glycinate and chelate compound is applied in the field of preparation of zinc-containing chelate compound, which can solve the problems of time-consuming and energy-consuming, difficult to industrialized production, complicated preparation process, etc., and achieves low energy consumption, fast reaction speed and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

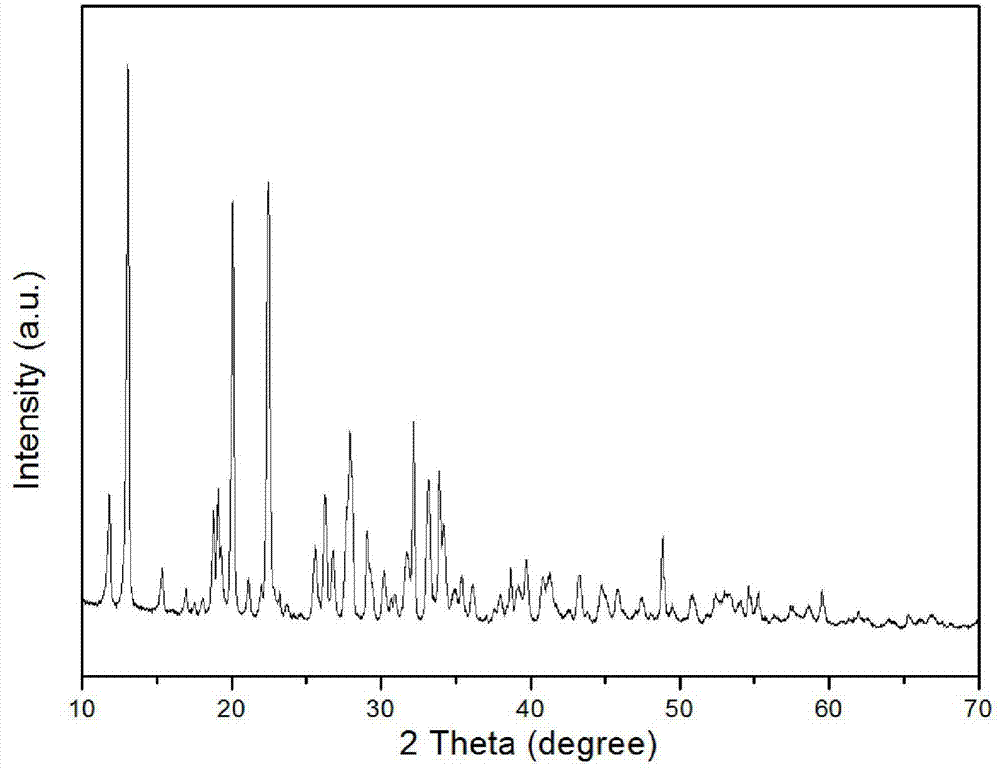

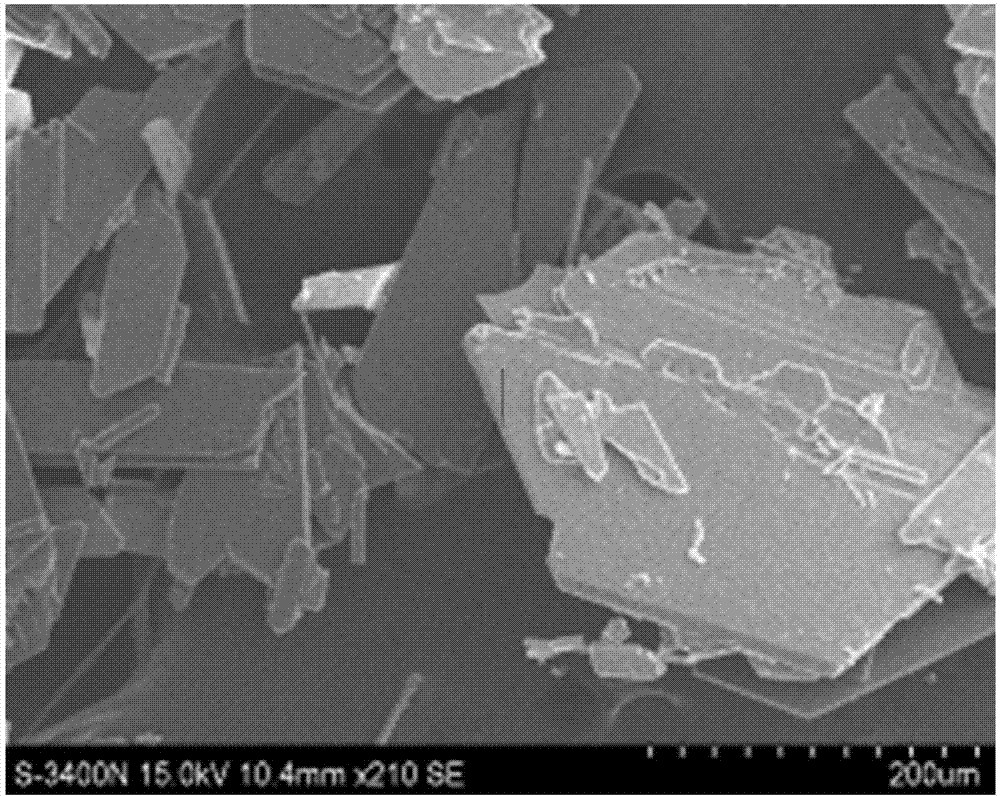

Image

Examples

Embodiment 1

[0020] (1), weigh 13.9g of ZnSO 4 ·7H 2 O, added to 25ml deionized water, stirred to form ZnSO with a molar concentration of 2.0mol / L 4 Aqueous solution; weigh 7.5g of glycine, add it to 50ml deionized water, stir to form a glycine aqueous solution with a molar concentration of 2.0mol / L; weigh 4g of sodium hydroxide, add it to 100ml deionized water, and stir to form a molar concentration It is 1.0mol / L sodium hydroxide aqueous solution.

[0021] (2), the ZnSO 4 The aqueous solution and the sodium hydroxide aqueous solution were poured into two separating funnels respectively, and were added dropwise in the glycine aqueous solution simultaneously, and the titration rate of the zinc salt solution and the sodium hydroxide solution was adjusted to be 5ml / min, and the pH value of the control reaction solution was 6.0 , The molar ratio of zinc salt and glycine added is 2:1. The reaction resulted in a white precipitate, which was aged in the mother liquor for 12 hours.

[0022] ...

Embodiment 2

[0025] (1), weigh 13.9g of ZnSO 4 ·7H 2 O, added to 25ml deionized water, stirred to form ZnSO with a molar concentration of 2.0mol / L 4 Aqueous solution; weigh 7.5g of glycine, add it to 50ml deionized water, stir to form a glycine aqueous solution with a molar concentration of 2.0mol / L; weigh 4g of sodium hydroxide, add it to 100ml deionized water, and stir to form a molar concentration It is 1.0mol / L sodium hydroxide aqueous solution.

[0026] (2), the ZnSO 4 The aqueous solution and the sodium hydroxide aqueous solution were poured into two separating funnels respectively, and were added dropwise in the glycine aqueous solution simultaneously, and the titration rate of the zinc salt solution and the sodium hydroxide solution was adjusted to be 5ml / min, and the pH value of the control reaction solution was 5.0 , The molar ratio of zinc salt and glycine added is 2:1. A white precipitate was obtained in the reaction, and the precipitate was aged in the mother liquor for 8h...

Embodiment 3

[0029] (1), weigh 13.9g of ZnSO 4 ·7H 2 O, added to 25ml deionized water, stirred to form ZnSO with a molar concentration of 2.0mol / L 4 Aqueous solution; weigh 7.5g of glycine, add it to 50ml deionized water, stir to form a glycine aqueous solution with a molar concentration of 2.0mol / L; weigh 4g of sodium hydroxide, add it to 100ml deionized water, and stir to form a molar concentration It is 1.0mol / L sodium hydroxide aqueous solution.

[0030] (2), ZnSO Aqueous solution and sodium hydroxide aqueous solution are poured in two separating funnels respectively, are added dropwise in glycine aqueous solution simultaneously, the titration rate of adjusting zinc salt solution and sodium hydroxide solution is 5ml / min, and control reaction The pH value of the solution is 5.5, and the molar ratio of zinc salt and glycine added is 2:1. A white precipitate was obtained in the reaction, and the precipitate was aged in the mother liquor for 15 hours.

[0031] (3) The white precipitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com