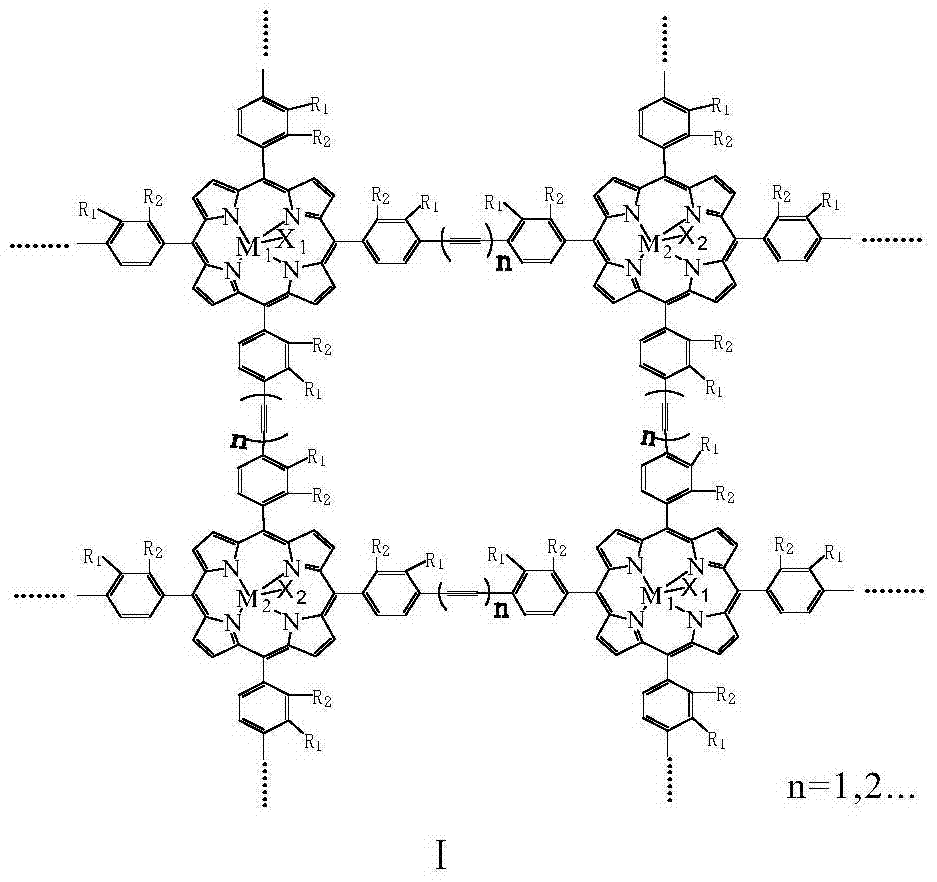

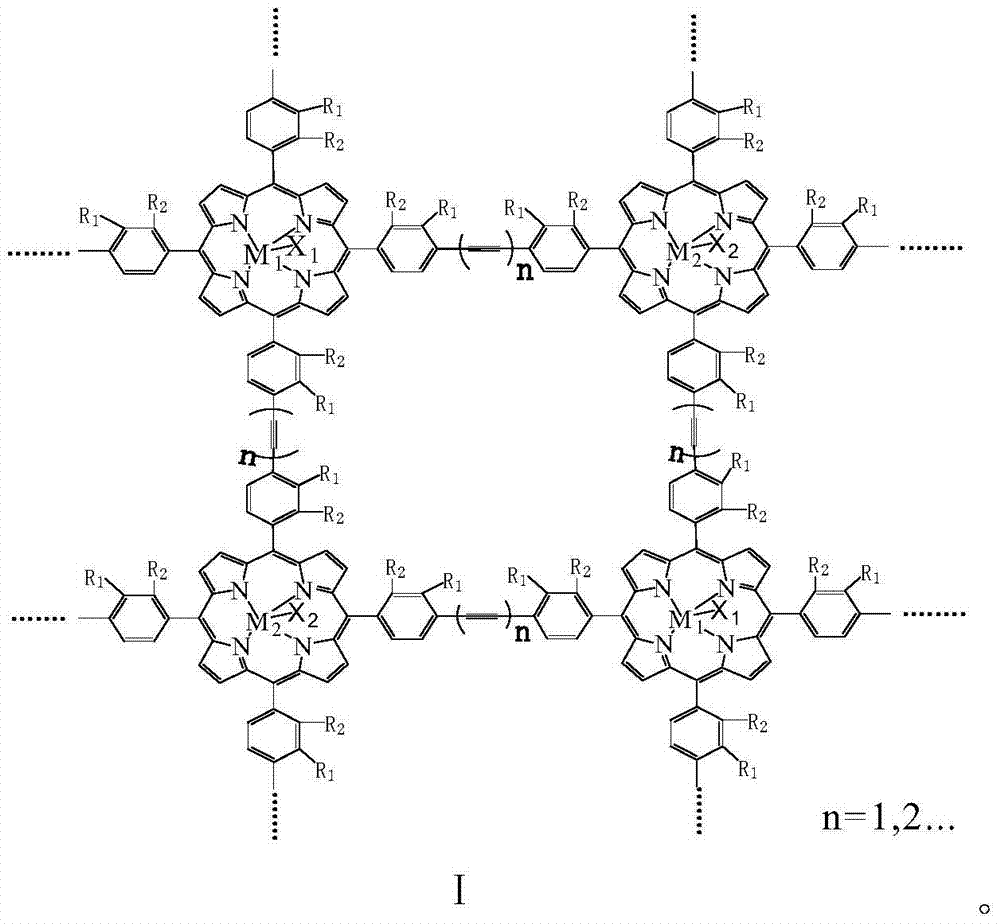

Method for catalytically oxidizing alkane and cycloparaffin by use of conjugated polymetalloporphyrin

A technology for polymerizing metals and metalloporphyrins, applied in chemical instruments and methods, catalytic reactions, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] With 20mg of the metalloporphyrin polymer with structural formula I structure, R 1 =R 2 = H, M 1 = M 2 =Mn,X 1 =X 2 =Cl, n=1, molecular weight is 115000, specific surface area is 860m 2 / g, was added to 500ml cyclohexane, and 8atm air was introduced. The reactant was stirred at 125° C. for 2 hours, the conversion rate of cyclohexane was 18.1%, and the total yield of cyclohexanol and cyclohexanone in the reaction product was 92%.

Embodiment 2

[0015] With 20mg of the metalloporphyrin polymer with structural formula I structure, R 1 = H, R 2 =CH 3 ,M 1 = M 2 =Fe,X 1 =X 2 =Cl, n=2, molecular weight is 53000, specific surface area is 750m 2 / g, was added to 500ml cyclohexane, and 8atm air was introduced. The reactant was stirred at 100° C. for 4 hours, the conversion rate of cyclohexane was 8.6%, and the total yield of cyclohexanol and cyclohexanone in the reaction product was 94%.

Embodiment 3

[0017] With 20mg of the metalloporphyrin polymer with structural formula I structure, R 1 =R 2 =Cl,M 1 =Mn,M 2 =Fe,X 1 =X 2 =Cl, n=1, molecular weight is 172000, specific surface area is 970m 2 / g, add 500ml of cyclohexane, and introduce l0atm air. The reactant was stirred at 130° C. for 2 hours, the conversion rate of cyclohexane was 21.4%, and the total yield of cyclohexanol and cyclohexanone in the reaction product was 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com