Advanced treatment method for coking wastewater

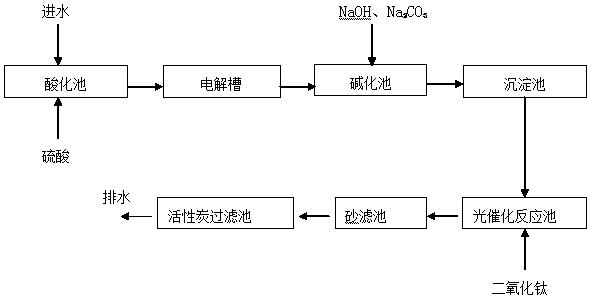

A coking wastewater and advanced treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem that the COD concentration cannot meet the discharge standard, coking wastewater cannot be effectively treated, wastewater Problems such as large chroma, achieve good treatment effect, solve limitations, and stabilize effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The water quality of coking wastewater produced by the biological treatment unit of a coking plant is shown in Table 1. Adopt processing method of the present invention to process, operate as follows:

[0032] The coking wastewater after biological treatment enters the acidification tank, adjusts the pH value of the wastewater to 5 with sulfuric acid, and then enters the electrolytic cell. Electrode plates are installed in the electrolytic cell, and the anode is Ti / SnO 2 , the cathode is Fe, the distance between the anode and the cathode is 1cm, it is powered by a constant voltage and constant current power supply, and the current density is 20mA / cm 2 , the electrolysis time is 60min, the wastewater is continuously fed, and the water plate ratio is 0.3cm 2 / cm 3 ; After the electrolytic treatment, the wastewater enters the alkalization tank, and the pH value of the wastewater is adjusted to 9 with NaOH, the amount of PFS added is 0.3‰, the amount of PAM added is 0.1‰ ...

Embodiment 2

[0036] The water quality of coking wastewater produced by the biological treatment unit of a coking plant is shown in Table 2. Adopt processing method of the present invention to process, operate as follows:

[0037] The coking wastewater after biological treatment enters the acidification tank, adjusts the pH value of the wastewater to 7 with sulfuric acid, and then enters the electrolytic cell. Electrode plates are installed in the electrolytic cell, and the anode is Ti / PbO 2 , the cathode is Al, the distance between the anode and the cathode is 3cm, it is powered by a constant voltage and constant current power supply, and the current density is 40mA / cm 2 , the electrolysis time is 90min, the wastewater is continuously fed, and the water plate ratio is 0.1cm 2 / cm 3 ; After the electrolytic treatment, the wastewater enters the alkalization pool and is treated with Na 2 CO 3Adjust the pH value of the wastewater to 9, add PAC to 0.2‰, add PAM to 0.1‰ (volume ratio), stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com