Idle sealing and explosion suppression device used for dangerous chemical containers and defense method

A technology for hazardous chemicals and containers, which is used in the field of safe production, storage and transportation of hazardous chemicals, and can solve problems such as easy deformation of floating trays, inert lining gas that cannot be recycled, and firefighting functions limited to emergency rescue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

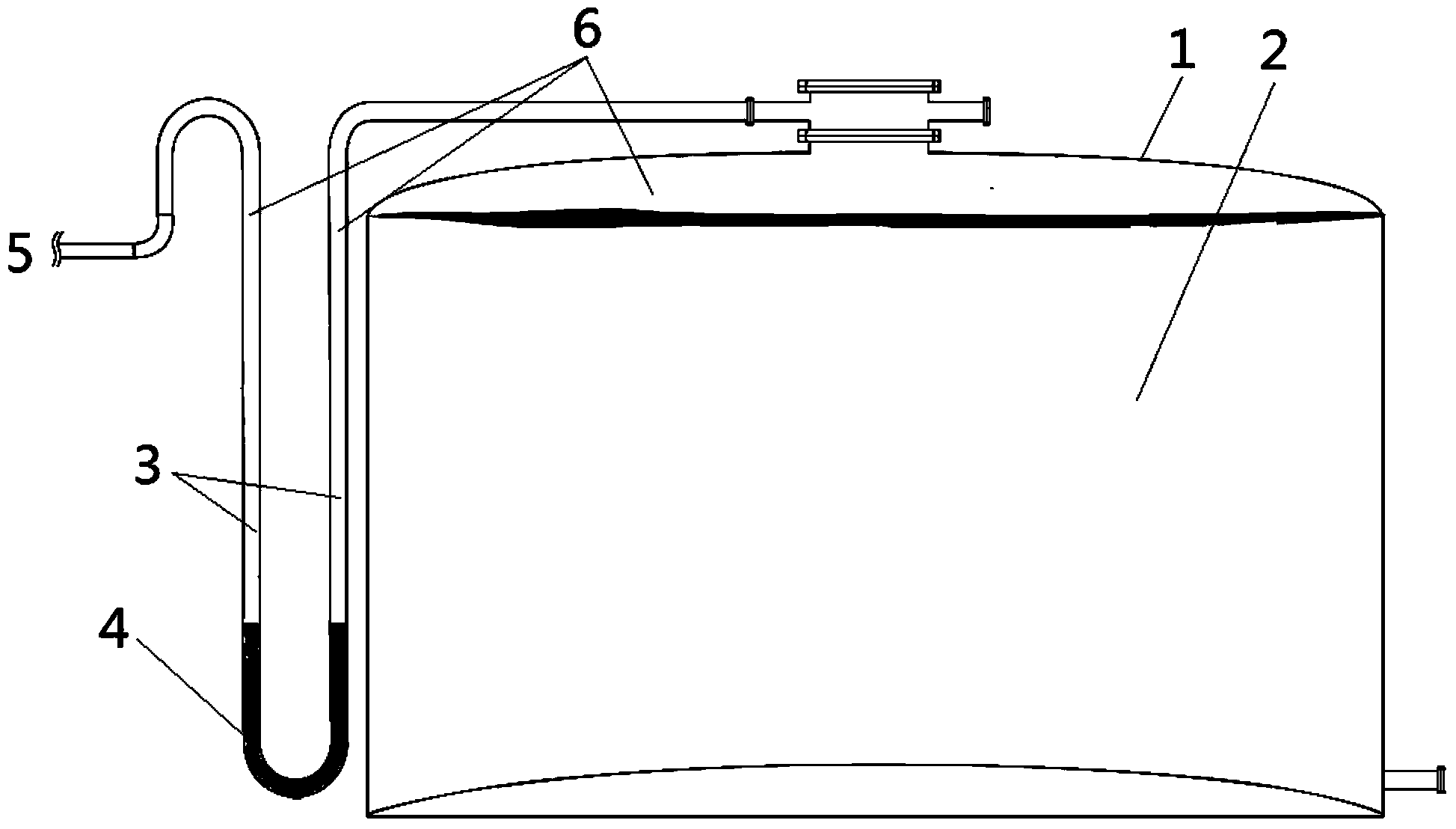

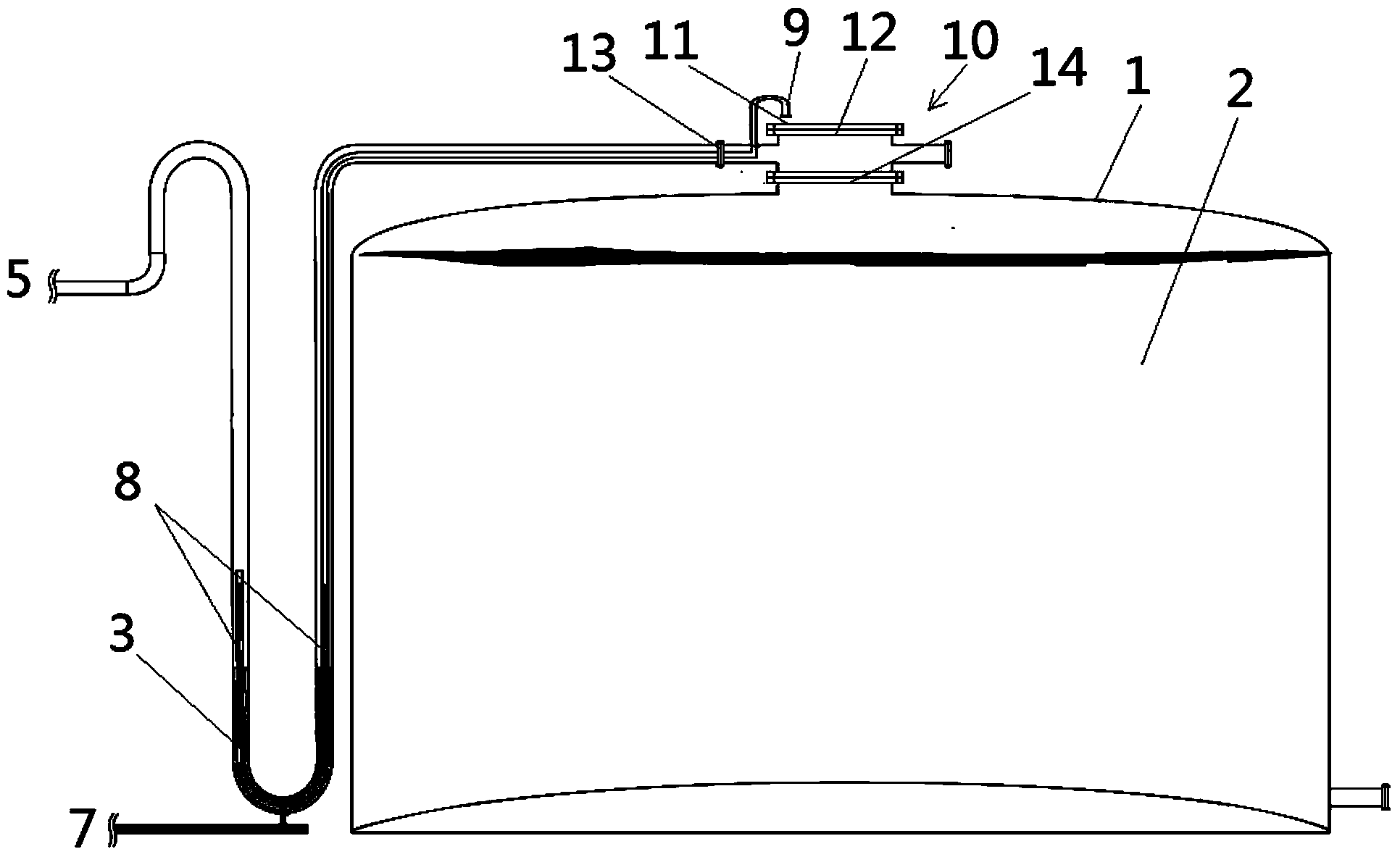

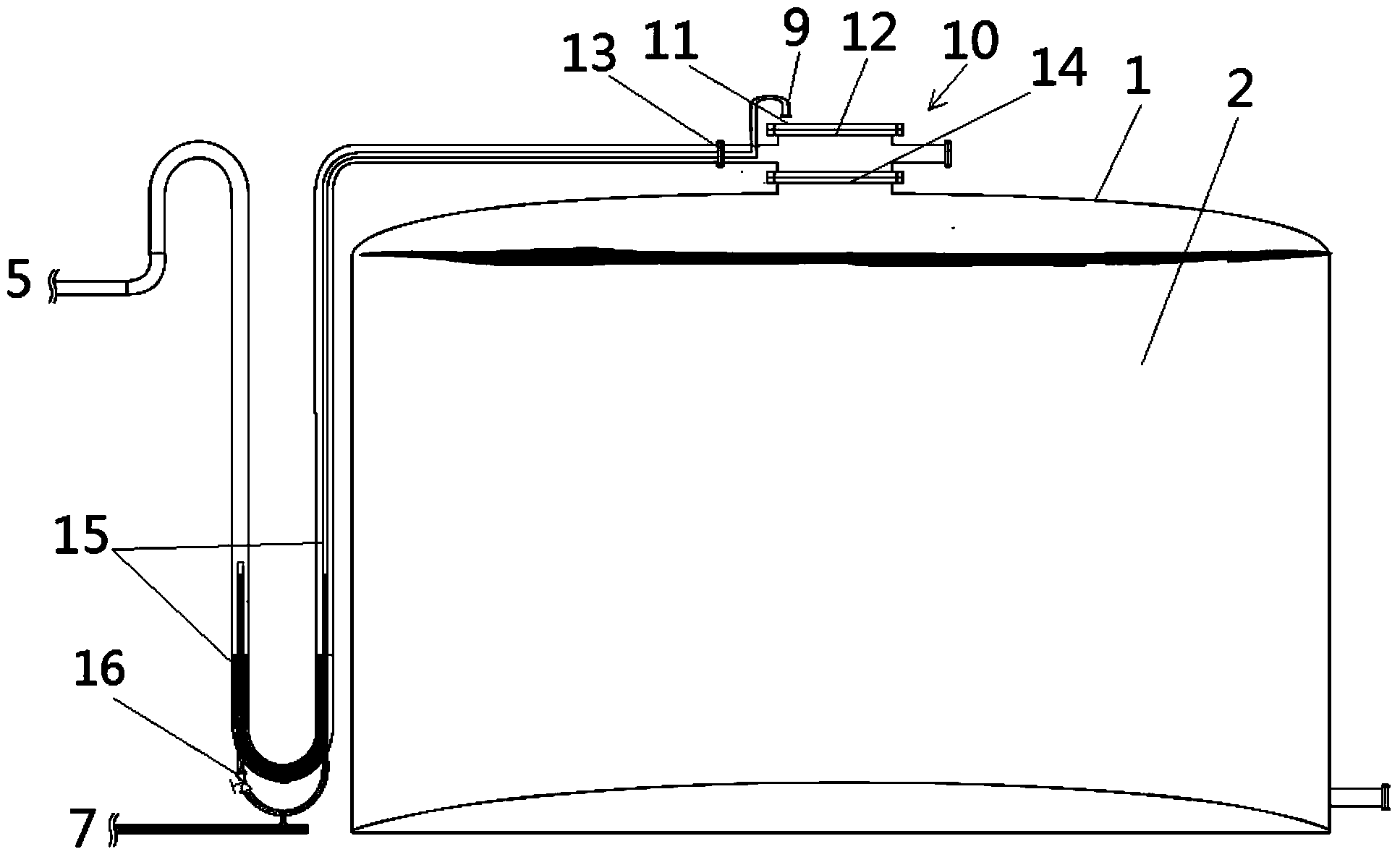

[0074] Such as figure 1Shown is a schematic structural view of an embodiment of the inert seal explosion suppression equipment for hazardous chemical containers of the present invention. In this embodiment, the inert seal explosion suppression equipment for hazardous chemical containers includes an inert seal device arranged on the hazardous chemical container 1, the inert seal device includes a U-shaped sleeve 3 installed in the vertical direction, and the U-shaped sleeve The liquid fire-fighting medium with fire-fighting function is stored in the pipe 3 relative to the protected materials in the hazardous chemical container. The two ends of the U-shaped bushing 3 are respectively connected to the lower port of the vertical pipe on the gas distribution side and the lower port of the vertical pipe on the container sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com