Sliding self-adaptive plasticizing extruding device and method

An extrusion device and self-adaptive technology, applied in the field of sliding self-adaptive plasticizing extrusion device, can solve the problem of accelerated changes in the type of processed materials and output, the mixing capacity cannot reach the same direction of the double screw, and the mixing task cannot be undertaken. problems, to achieve excellent dispersion, distribution and mixing effect, excellent extrusion characteristics, and the effect of improving melting and mixing and kneading capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

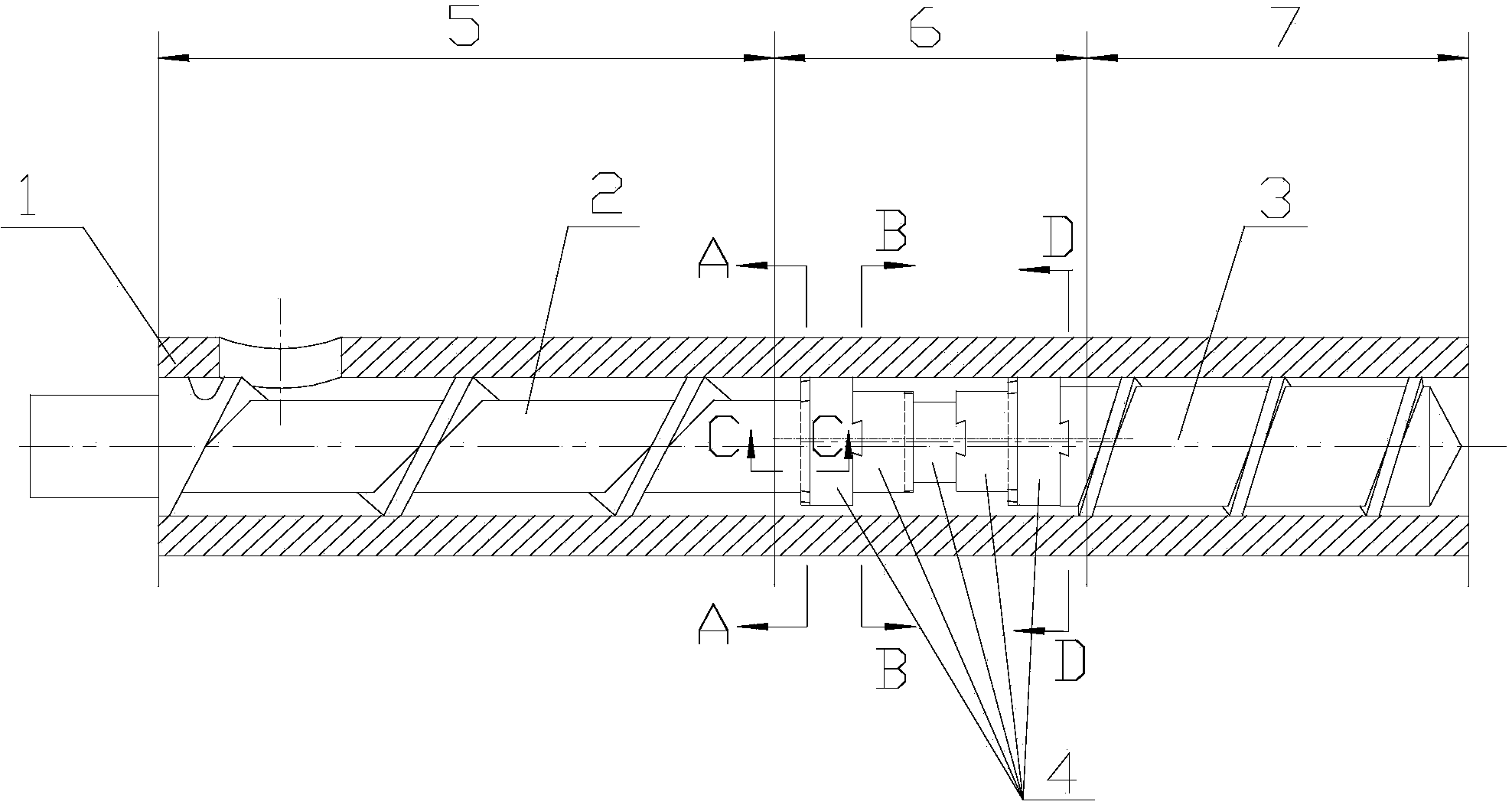

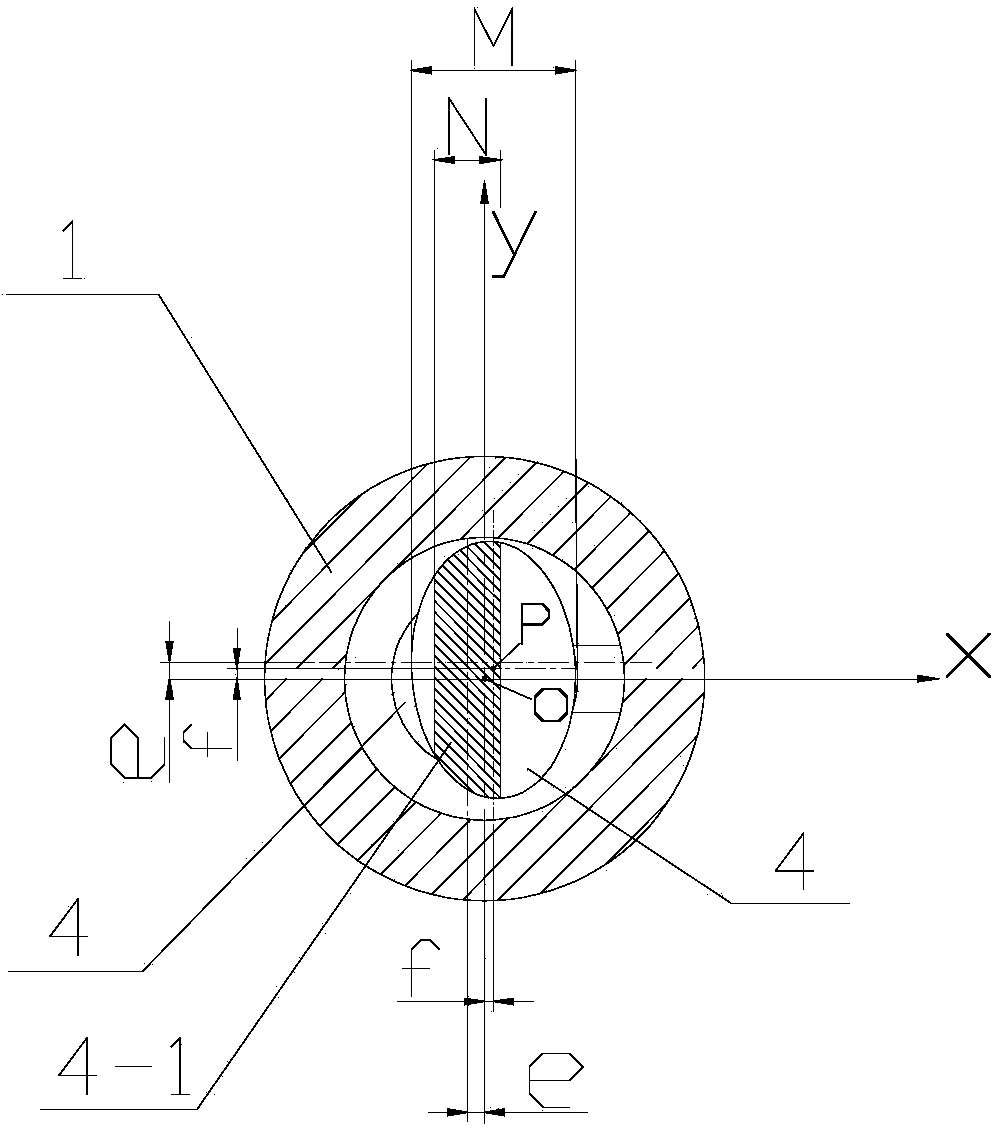

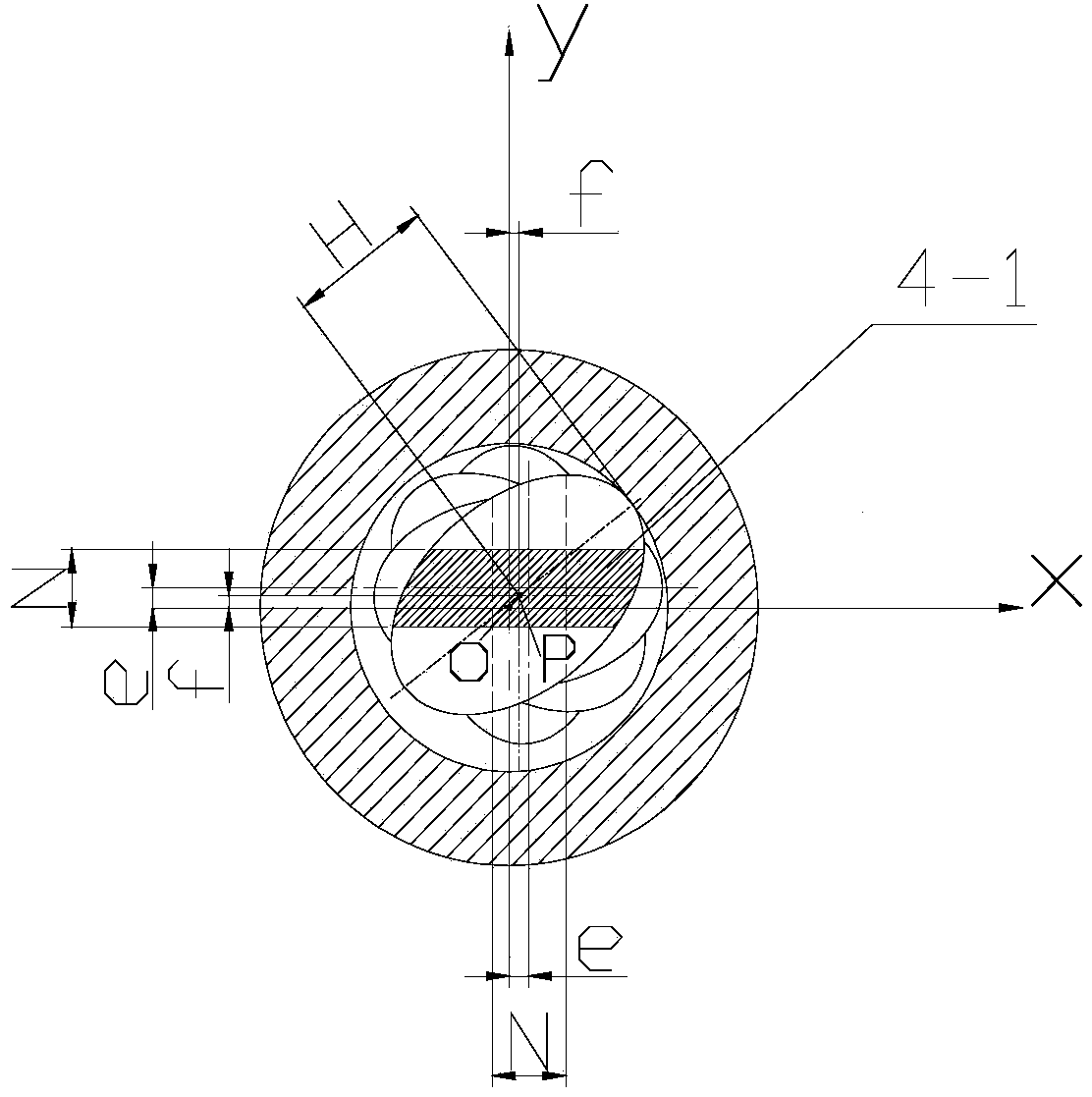

[0049] In this embodiment, a sliding self-adaptive plasticizing extrusion device, such as figure 1 As shown, it includes a barrel 1 and a screw mechanism located in the barrel. The screw mechanism includes a coaxially arranged forced feeding screw 2 and a metering extrusion screw 3. The forced feeding screw and the metering extrusion screw are rotated eccentrically. The components are connected; the eccentric rotating component includes a plurality of eccentric rotating disks 4 arranged coaxially, and two adjacent eccentric rotating disks are engaged and connected by chute; the barrel includes a solid conveying section 5, a melting and mixing section 6 and In the metering extrusion section 7, the forced feeding screw is located in the solid conveying section of the barrel, the eccentric rotating assembly is located in the melting and mixing section of the barrel, and the metering extrusion screw is located in the metering extrusion section of the barrel. Among them, the forced...

Embodiment 2

[0062] This embodiment is a sliding type self-adaptive plasticizing extrusion device. Compared with Embodiment 1, the difference is that the eccentric rotating components are reversed at a staggered angle of 45° (that is, the rotation direction of each eccentric rotating disk is the same as that of the forced The feeding screw and the screw on the metering extrusion screw rotate in the opposite direction) to transport the material.

Embodiment 3

[0064] This embodiment is a kind of sliding self-adaptive plasticizing extrusion device, compared with embodiment 1, its difference is that, such as Figure 8 As shown, the eccentric rotating assembly includes 7 elliptical eccentric rotating disks, and each eccentric rotating disk is arranged at a staggered angle of 30°; on the same eccentric rotating disk, the angle between the axes of the two dovetail grooves is 30°; the same On the eccentric rotating disc, the included angle between the axes of the two projections is 30°. During the material conveying process, the eccentric rotating assembly adopts a staggered angle of 30°forward (that is, the rotating direction of each eccentric rotating disc is the same as the screw rotating direction on the forced feeding screw and the metering extrusion screw) to carry out material conveying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com