Stir friction both-side welding method for medium-thickness plate

A friction stir and double-sided welding technology, applied in welding equipment, non-electric welding equipment, welding/welding/cutting items, etc., can solve the problem of low connection strength, improve mechanical properties, reduce thermal gradient, and improve plastic flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

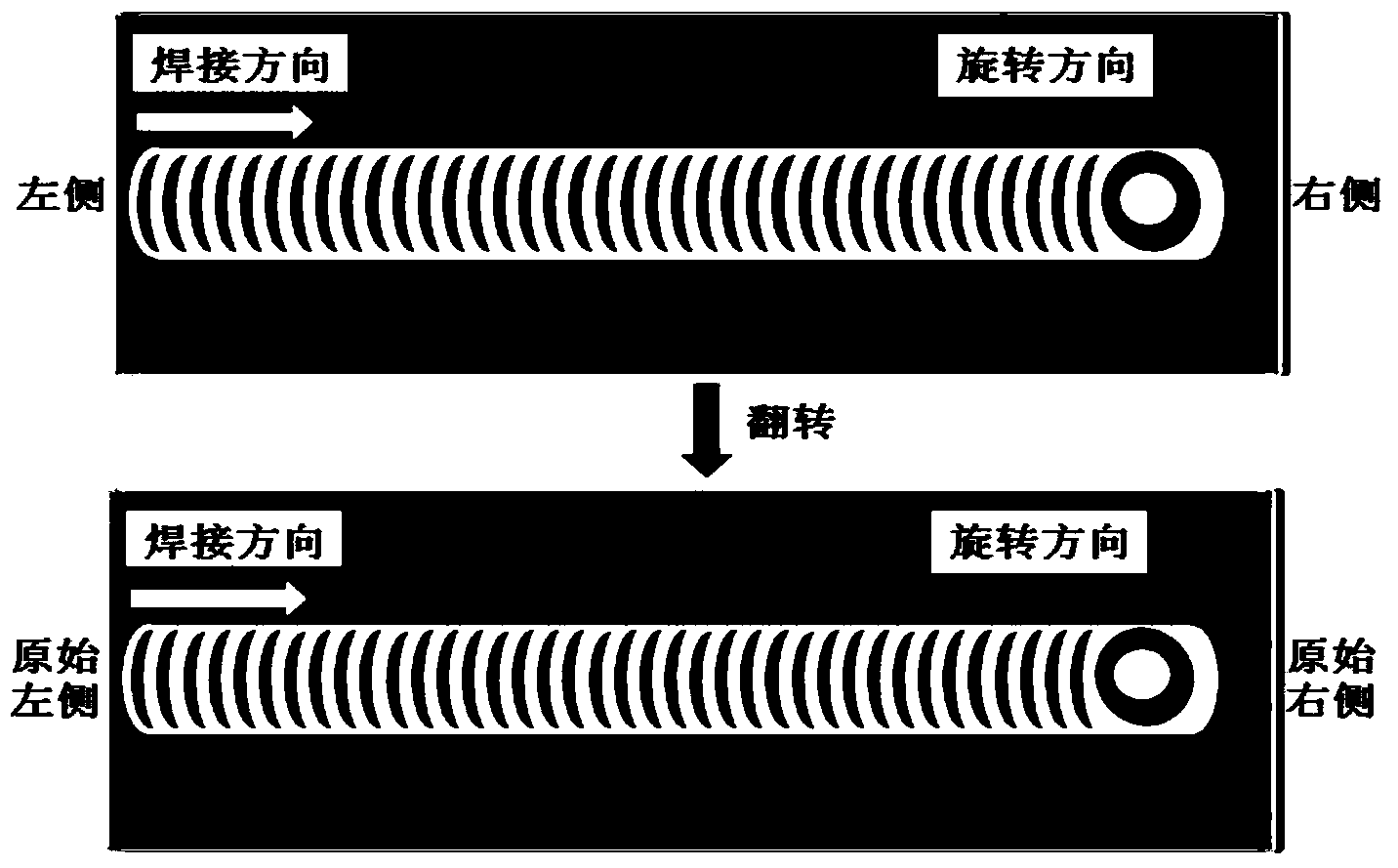

Embodiment 1

[0018] The 10mm thick rare earth magnesium alloy plate is docked and fixed on the backing plate; the shaft shoulder of the stirring head is in the shape of a double concave ring, with a diameter of 20mm; mm. Center the rotating stirring head with the welding face. When starting welding, the stirring head is inserted into the starting position of welding at an insertion speed of 20mm / min, and the pressing amount of the shoulder is 0.2mm, and stays for 2s; when starting to move, keep the rotating speed of the stirring head at 600r / min, and the welding speed is 80mm / min ; After the stirring head stops moving, stay for 2 seconds and pull out the stirring head, and the welding is completed, and a weld seam is obtained. Turn the workpiece over, and use the back of the starting position of the primary welding seam as the starting position of the secondary welding, and perform the same direction welding of the secondary welding seam, and the welding parameters are the same as steps 2...

Embodiment 2

[0021] The 10mm thick rare earth magnesium alloy plates are docked and fixed on the backing plate; the preparation method of the primary weld is the same as in Example 1 to obtain the primary weld; the workpiece is turned over, and the back of the primary weld end position is used as the starting point of the secondary weld. At the initial position, the anisotropic welding of the secondary weld seam is carried out, and the welding parameters are the same as in Embodiment 1. The complete weld seam of friction stir double-sided welding is obtained at the end of welding.

[0022] The upper and lower surfaces of the welded joint are well-formed, without major deformation, and without obvious defects; the quasi-static tensile mechanical performance test shows that the tensile strength of the joint is 267.8MPa, reaching 89.3% of the strength of the base metal, and the fracture is located at the thermal area of influence.

Embodiment 3

[0024] The 20mm thick AZ80 magnesium alloy is butted in the same direction by friction stir double-sided welding, and the tensile strength of the base metal is 299MPa. The plates are butted and fixed on the backing plate. The shaft shoulder of the stirring head used is in the shape of a double concave ring with a diameter of 22mm; the stirring needle is a conical right-handed thread with a diameter of 6-10mm and a length of 9.7mm. The process parameters of the two welding are the same, respectively: the welding rotation speed is 250r / min, the welding speed is 80mm / min, and the pressing amount is 0.2mm. Finally, a complete weld seam of friction stir double-sided welding in the same direction is obtained.

[0025] The upper and lower surfaces of the welded joint are well formed without obvious defects; the quasi-static tensile mechanical property test shows that the tensile strength of the joint is 262.2MPa, reaching 87.7% of the base metal strength, and the fracture position is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com