Large gear adhesive belt tooth grinding machine

A large-scale gear and gear grinding machine technology, applied in the direction of belts/chains/gears, gear teeth, mechanical equipment, etc., can solve the problems of expensive, difficult to realize, and uneconomical large-grained diamonds, and achieve a good residual stress state, The effect of stable grinding speed and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

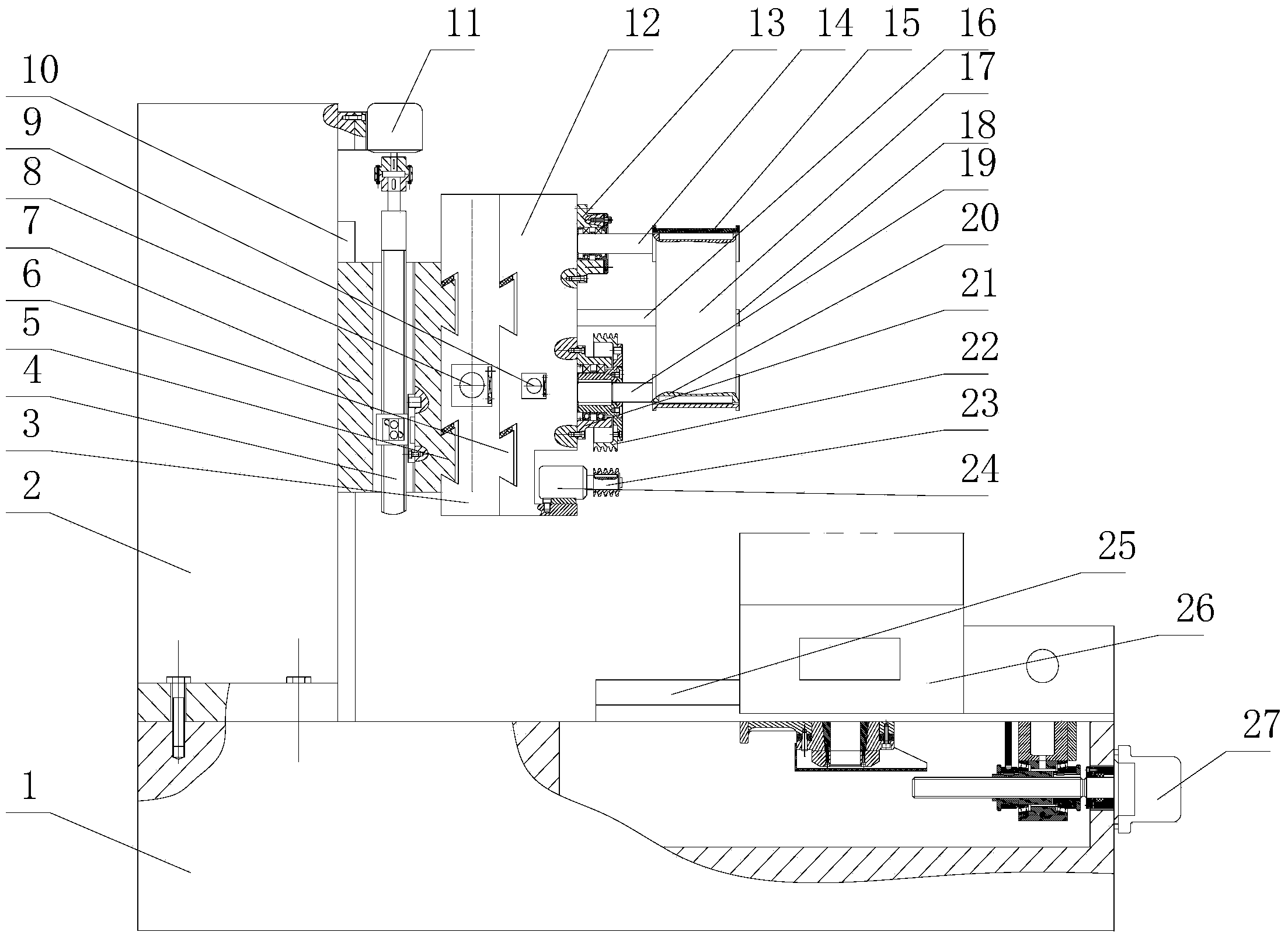

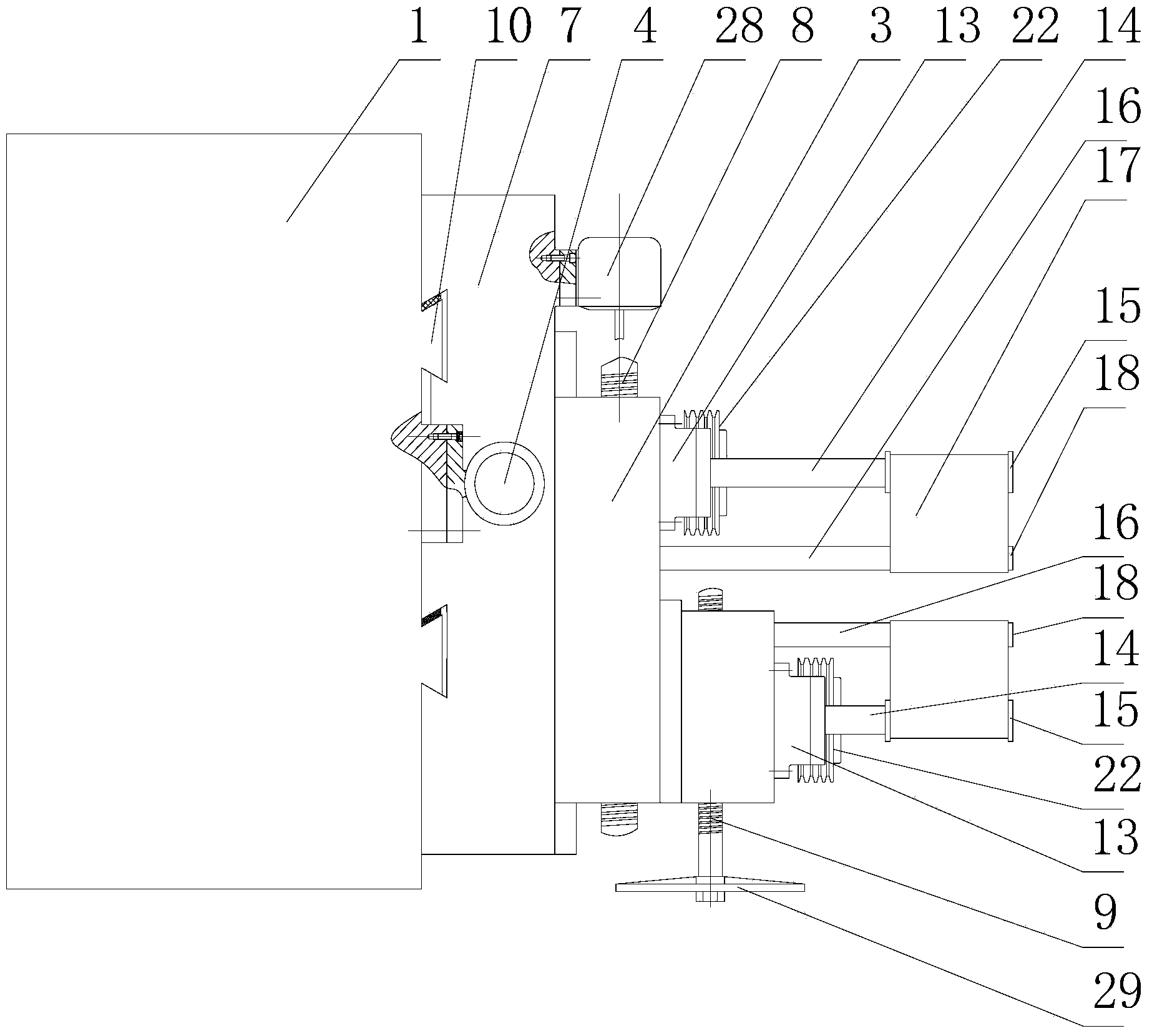

[0039] The specific embodiment of the present invention is shown in the accompanying drawings, including a machine base 1, a column 2, a rotary table 26, a servo motor 11, a ball screw I4 and a power head; it is characterized in that the said rotary table 26 is mounted on the machine base One end of the upper part of 1; the other end of the upper part of the base 1 is equipped with a column 2; the power head is installed on the column 2 through the dovetail guide rail I10; the servo motor 11 is installed on the column 2; the servo motor 11 and the ball wire installed on the power head The bars I4 are connected to drive the power head to move up and down along the direction of the dovetail guide rail I10; the rotary table 26 is installed on the machine base 1 through the guide rail 25, and the rotary table 26 is connected with the fast oil cylinder 27 installed on the machine base 1, And move left and right along guide rail 25 under the drive of fast oil cylinder 27.

[0040] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com