A kind of starch-based polymer electrolyte for lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and polymers, which is applied in the manufacture of electrolyte batteries, solid electrolytes, non-aqueous electrolytes, etc., can solve the problems of low lithium ion migration number, low ion conductivity, and low production cost, so as to improve the migration rate, Effect of high ionic conductivity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

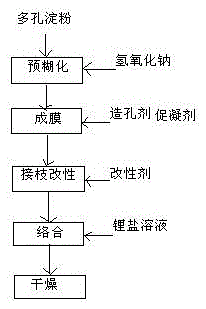

Method used

Image

Examples

Embodiment 1

[0037] 1) Dissolving 65 parts by weight of corn porous starch in distilled water at 30 degrees Celsius in a reaction kettle to form a solution, then heating up to 80 degrees Celsius, adding 2 parts of sodium hydroxide for pregelatinization treatment, and obtaining porous starch sol;

[0038]2) Add 2 parts by weight of sodium borate and 5 parts by weight of methanol to the porous starch sol obtained in step 1), fully stir and mix for 30 minutes to obtain a casting solution, and scrape it on a glass plate after vacuum defoaming treatment. Naturally solidify for 2 hours, and after film formation, place it in an oven heated to 50 degrees Celsius for 1 hour to volatilize the pore-forming agent to obtain a porous starch film;

[0039] 3) Immerse the porous starch film obtained in step 2) into an irradiation tube containing 5 parts by weight of a polyurethane modifier, perform graft modification treatment for 40 minutes under the condition of ultraviolet radiation, and take out the mo...

Embodiment 2

[0042] 1) Dissolving 80 parts by weight of potato porous starch in distilled water at 30 degrees Celsius in a reaction kettle to form a solution, then heating up to 75 degrees Celsius, adding 4 parts of sodium hydroxide for pregelatinization treatment, to obtain porous starch sol;

[0043] 2) Add 5 parts by weight of thiazole coagulant accelerator and 10 parts by weight of ethanol to the porous starch sol obtained in step 1), stir and mix for 60 minutes to obtain a casting solution, and scrape it on a glass plate after vacuum defoaming treatment 3 hours of natural solidification, and after the film is formed, place it in an oven heated to 80 degrees Celsius for 2 hours to volatilize the pore-forming agent to obtain a porous starch film;

[0044] 3) Immerse the porous starch film obtained in step 2) into an irradiation tube containing 3 parts by weight of a polycarboxylate modifier, and carry out graft modification treatment for 20 minutes under the condition of low-temperature ...

Embodiment 3

[0047] 1) Dissolving 70 parts by weight of konjac porous starch in distilled water at 40 degrees Celsius in a reaction kettle to form a solution, then warming up to 70 degrees Celsius, adding 3 parts of sodium hydroxide for pregelatinization treatment to obtain porous starch sol;

[0048] 2) Add 2-5 parts by weight of diphenylguanidine coagulant and 10 parts by weight of propanol to the porous starch sol obtained in step 1), and fully stir and mix for 40 minutes to obtain the casting solution. After vacuum defoaming treatment Scratch coating on a glass plate, let it solidify naturally for 3 hours, and place it in an oven heated to 80 degrees Celsius for 1 hour after forming a film to volatilize the pore-forming agent to obtain a porous starch film;

[0049] 3) Immerse the porous starch film obtained in step 2) into an irradiation tube containing 4 parts by weight of a polyether modifier, perform graft modification treatment for 40 minutes under the condition of high-energy ray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com