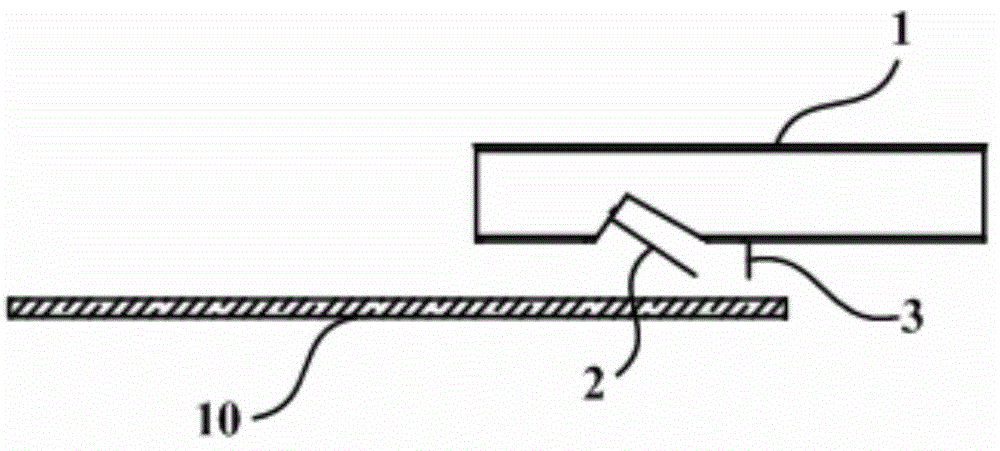

Apparatus for removing photoresist at edge of substrate

A technology of edge light and photoresist, which is applied in the direction of spraying device, spraying device, photosensitive material processing, etc., can solve the problems of photoresist dissolver blowing to the substrate, photoresist dissolver being resisted, splashing, etc. Achieve the effect of avoiding sputtering into the substrate, avoiding substrate defects, and reducing defective points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

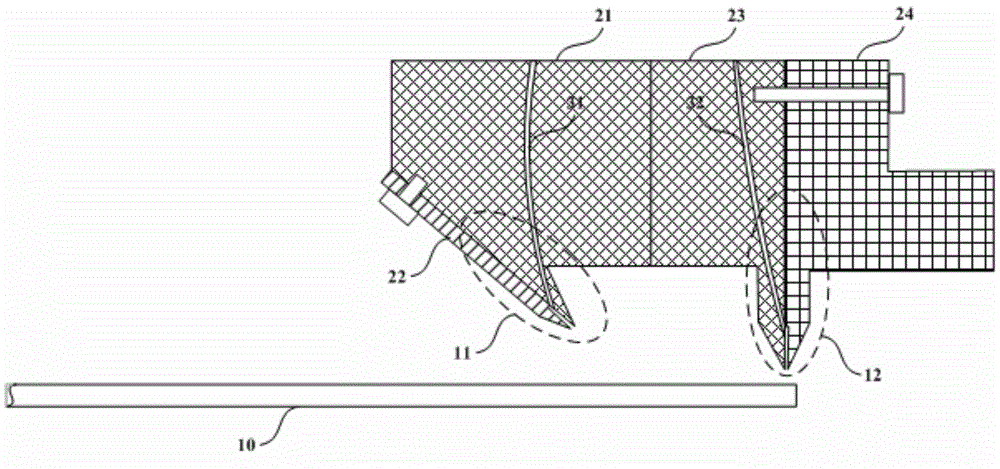

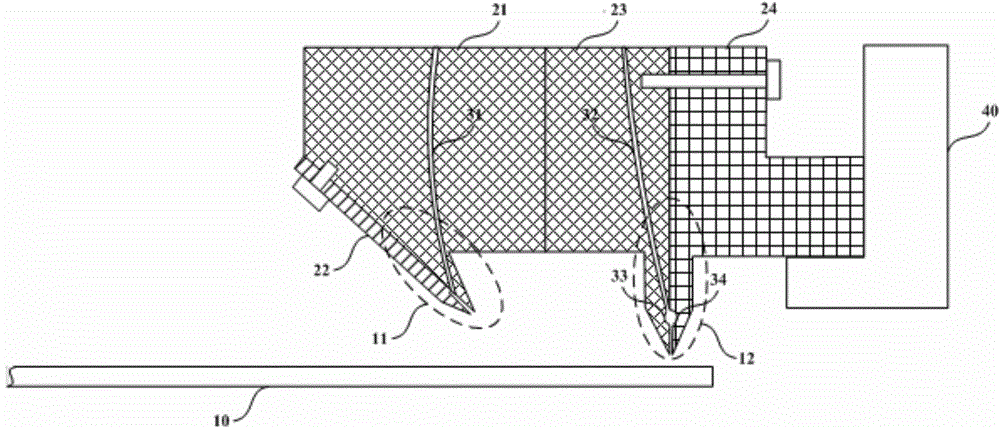

[0033] In order to effectively prevent nozzle clogging, an embodiment of the present invention provides a device for removing photoresist at the edge of a substrate. In this technical solution, due to the use of slit-shaped gas nozzles or slit-shaped liquid nozzles, compared with the existing needle-shaped nozzles, it is not easy to be blocked, and it is easier to eject gas or liquid smoothly, and will not cause the photoresist dissolver to be damaged. Sputtering occurs due to blockage or deformation of the needle-shaped nozzle, which avoids the occurrence of defective substrates caused by sputtering photoresist dissolvers inside the substrate. In order to make the purpose, technical solution and advantages of the present invention clearer, the following specific examples are given to further describe the present invention in detail.

[0034] An embodiment of the present invention provides a device for removing photoresist at the edge of a substrate, such as figure 2 as show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slit width | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com