Rotor high-low pressure power device and work doing method of rotor high-low pressure power device

A power equipment, high and low pressure technology, applied in the field of thermal power equipment, can solve the problems of complex structure, high manufacturing cost and high cost of internal combustion engine radial engine, and achieve the effects of light weight, high running speed and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

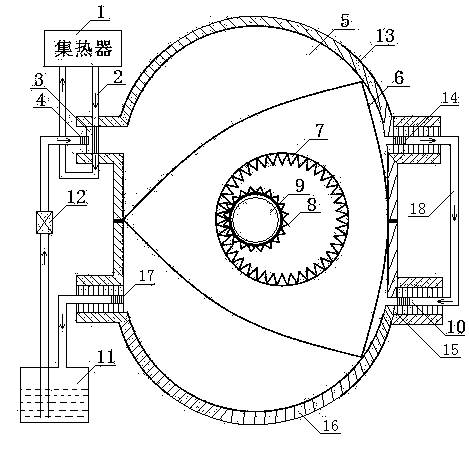

[0030] A rotor high and low pressure power equipment, including heat collector 1, heat preservation pipe 2, gasification reactor 3, atomizer 4, cylinder 5, triangular rotor 6, inner ring gear 7, gear 8, output shaft 9, one-way Air intake valve 10, liquid storage tank 11, pressure valve 12, insulation layer 13, automatic exhaust valve 14, casing 15, radiator 16, exhaust control valve 17 and buffer pipe 18; the casing 15 is provided with a triangular rotor 6. The center of the triangular rotor 6 is provided with an inner ring gear 7. The gear 8 matched with the inner ring gear 7 is fixed on the output shaft 9. The triangular rotor 6 divides the cylinder 5 into three uniform independent spaces. The inner ring gear 7 The ratio of the number of teeth to the gear 8 is 3:2; one side of the cylinder 5 is provided with a gasification reactor 3 and an exhaust control valve 17, and the other side of the cylinder 5 is provided with an automatic exhaust valve 14 and a one-way intake valve 1...

Embodiment 2

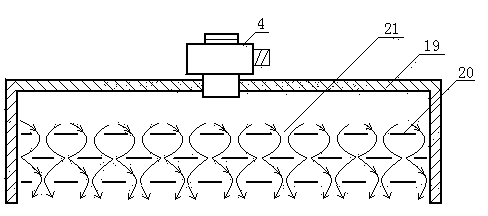

[0032] Like the rotor high and low pressure power equipment in Example 1, the gasification reactor 3 includes a pressure shell 19, a gasification heat conduction sheet 20, an air hole 21, and an atomizer 4, and the gasification heat conduction sheet 20 is arranged on the pressure shell 19, Air holes 21 are arrayed on the vaporization heat conducting sheet 29, and an atomizer 4 is provided at the inlet end of the pressure shell 19; the pressure valve 12 is associated with the output shaft 9, and the pressure valve opens and closes three times for each cycle completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com