Combined type power equipment

A power equipment and combined technology, which is applied in the direction of combined engines, mechanical equipment, machines/engines, etc., can solve the problems of high manufacturing cost and high cost, and achieve the effects of energy saving, low noise and increased power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

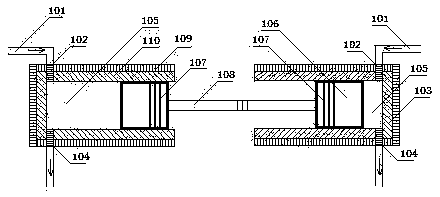

[0059] The output shaft of the existing in-line engine or V-type engine is combined with the output shaft of the heat energy power equipment to perform work. , atomizer 106, automatic vent 107, gasification reactor 108, cylinder 109, piston 110, piston ring 111, connecting pin 112, connecting rod 113, crankshaft 114, bearing 115, casing 116, refrigerator 117 , transmission shaft 118, liquid storage tank 119 and pipeline 120, cylinder 109 is provided with piston 110, piston 110 is provided with piston ring 111, piston 110 is connected to connecting rod 113 through connecting pin 112, connecting rod 113 is connected to crankshaft 114, crankshaft 114 There is a bearing 115, and the bearing 115 is fixed on the transmission shaft 118, and the transmission shaft 118 is fixed on the casing 116 through the bearing. One end of the transmission shaft 118 is provided with a pressure pump 105; one end of the pressure pump 105 is connected to the atomizer 106 through a pipeline 120, and the...

Embodiment 2

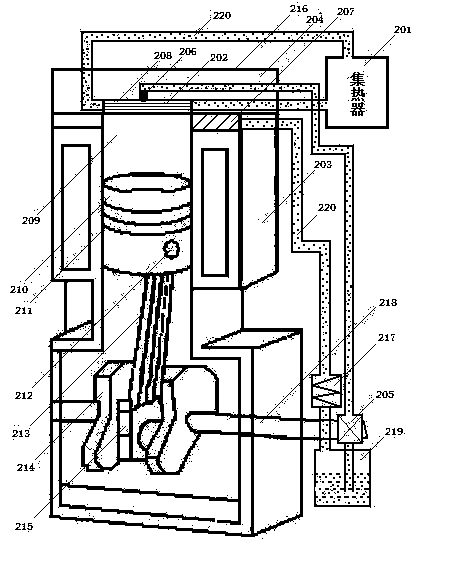

[0061]The output shaft of an existing in-line engine or V-type engine is combined with the output shaft of a parallel motion thermal power machine to perform work. The parallel motion thermal power machine includes a heat collector 201, an insulation pipe 202, a gasification reactor 203, and an atomizer 204, cylinder 205, piston 206, piston ring 207, automatic exhaust valve 208, cooler 209, liquid storage tank 210, pressure pump 211, push-pull rod 212, insulation layer 213 and casing 214; There are two cylinders 205, the cylinder 205 is provided with a piston 206, the piston 206 is provided with a piston ring 207, and the piston 206 is arranged at both ends of the push-pull rod 212; the heat collector 201 is connected to the gasification reactor 203 through the insulation pipe 202, the gasification The air inlet end of device 203 is provided with atomizer 204, and atomizer 204 is connected with pressure pump 211 through pipeline, and pressure pump 211 is connected with liquid s...

Embodiment 3

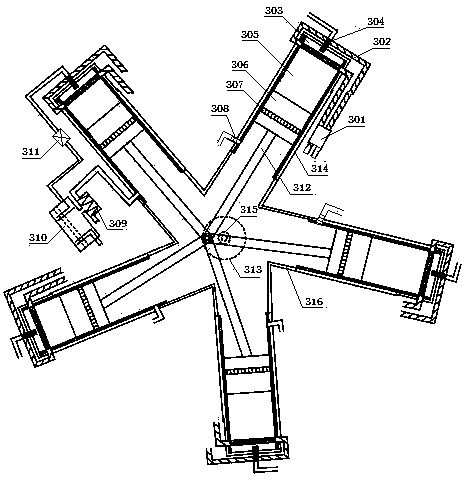

[0063] The output shaft of the existing in-line engine or V-type engine is combined with the output shaft of the in-line thermal power equipment to perform work. Device 304, cylinder 305, piston 306, piston ring 307, automatic exhaust valve 308, frame 309, insulation layer 310, liquid storage tank 311, cooler I312, cooler II313, pressure valve I314, pressure valve II315, crankshaft 316, flywheel 317, connecting rod 318 and rotating shaft 319; On the frame 309, four parallel cylinders 305 are arranged in a row; piston 306 is respectively arranged in the four cylinders 305, and piston ring 307 is provided on the piston 306; Rod 318, connecting rod 318 is connected to crankshaft 316, crankshaft 316 is connected to rotating shaft 319, rotating shaft 319 is fixed on the frame 309 through bearings, rotating shaft 319 is connected to flywheel 317; heat collector 301 is connected to gasification reactor 304 through insulation pipe 302 The gasification reactor 304 inlet end is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com