Parallel motion high-low pressure power device and application thereof

A technology of parallel motion and power equipment, which is applied in the direction of mechanical equipment, machine/engine, hot gas variable displacement engine device, etc., can solve the problems of high cost and high manufacturing cost, and achieve low manufacturing cost, low noise and high economic benefit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

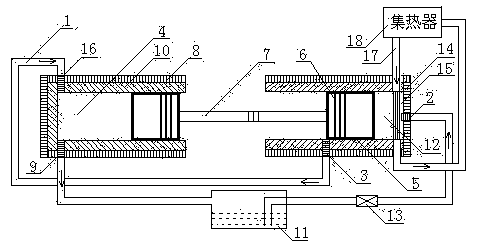

[0030] A high and low pressure power equipment with parallel movement, including connecting pipe 1, atomizer 2, exhaust valve 3, low pressure cylinder 4, piston 5, piston ring 6, push-pull rod 7, radiator 8, exhaust control valve 9, machine Frame 10, liquid storage tank 11, high-pressure cylinder 12, pressure valve 13, heater 14, gasification reactor 15, air intake check valve 16, heat preservation pipe 17 and heat collector 18; Piston 5, two pistons 5 are set in high pressure cylinder 12 and low pressure cylinder 4 respectively, piston ring 6 is set on piston 5; exhaust valve 3 is set at bottom dead point of high pressure cylinder 12, gasification reactor is set at top dead point 15. The gasification reactor 15 is provided with an atomizer 2 at the inlet end; the heat collector 18 is connected to the gasification reactor 15 through a heat preservation pipe 17; The air control valve 9 and the exhaust control valve 9 are connected to the liquid storage tank 11 through the conne...

Embodiment 2

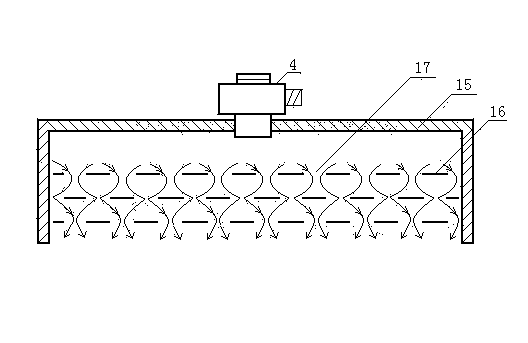

[0032] As in the parallel motion high and low pressure power equipment in the above-mentioned embodiment 1, the radiator 8 is made in the form of fins; a circulating pipeline is arranged on the radiator 8 and a circulating cooling medium is injected in the pipeline; in the low pressure cylinder 4 There is an exhaust control valve 9 on the top, which can automatically adjust the exhaust according to the temperature of the hot gas source; the intake check valve 16 is set in the middle of the top of the low-pressure cylinder 4; the exhaust control valve 9 is set at the lower part of the top dead center of the low-pressure cylinder 4; the radiator 8, a circulation pipeline is set and circulating cooling medium water is injected into the pipeline, and the circulating water is used for cooling; the gasification reactor 15 includes a pressure shell 19, a gasification heat conduction plate 20, an air hole 21, an atomizer 2, and a gasification heat conduction The sheet 20 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com