Horizontally opposed type negative pressure power device and working method thereof

A power equipment, opposing technology, applied in mechanical equipment, machines/engines, hot gas variable capacity engine devices, etc., can solve the problems of high manufacturing cost and high cost, and achieve low manufacturing cost, low center of gravity and high economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

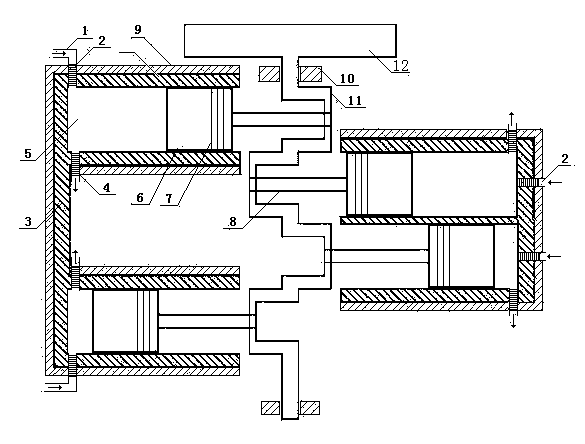

[0028] A horizontally opposed negative pressure power device, comprising a connecting pipe 1, an intake check valve 2, a cylinder head 3, an exhaust control valve 4, a cylinder 5, a piston 6, a piston ring 7, a connecting rod 8, a radiator 9, The casing 10, the crankshaft 11 and the flywheel 12; the cylinder 5 is horizontally opposed to the crankshaft 11 at an angle of 180°, the piston 6 is arranged in the cylinder 5, and the piston 6 is provided with a piston ring 7; The cylinder head 3 is provided with an intake check valve 2, the cylinder 5 is provided with an exhaust control valve 4, the intake check valve 2 is connected to the connecting pipe 1, the outer layer of the cylinder 5 is provided with a radiator 9, and the piston 6 is connected to the connecting rod 8. The connecting rod 8 is connected to the crankshaft 11, the crankshaft 11 is fixed to the casing 10 through bearings, and the crankshaft 11 is connected to the flywheel 12.

Embodiment 2

[0030] As in the horizontally opposed negative pressure power equipment in Embodiment 1, an intake check valve 2 is provided in the middle of the cylinder head 3, and an exhaust control valve 4 is provided on the cylinder 5, and the intake check valve 2 is connected to the connecting pipe 1. The connecting pipe 1 is connected to the hot gas outlet of the internal combustion engine or other hot gas sources; a circulating pipeline is arranged on the radiator 9 and circulating cooling medium water is injected into the pipeline, and the circulating water is used for cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com