A copper electroplating solution

A technology for electroplating copper and solution, applied in the field of metal electroplating, can solve the problems of reducing the thickness of the dielectric layer and increasing the feature aspect ratio, and achieves the effects of improving the step coverage, reducing the roughness and improving the reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

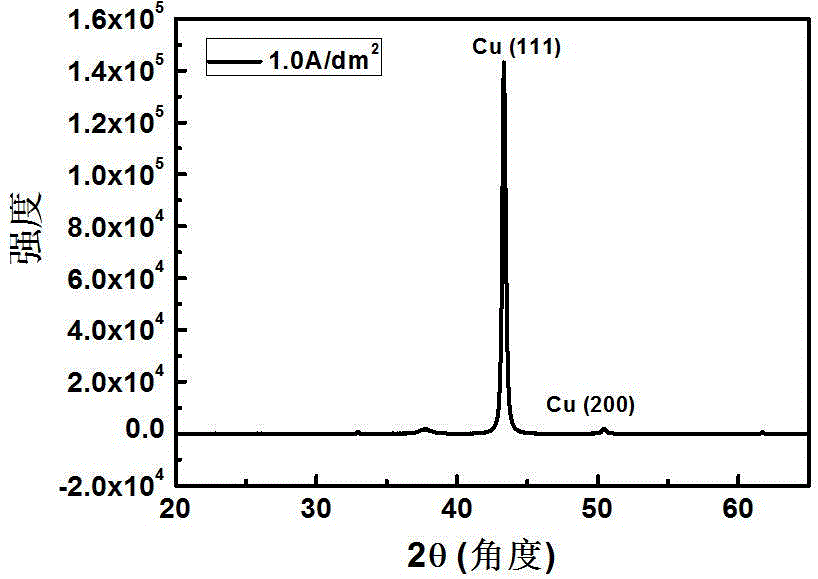

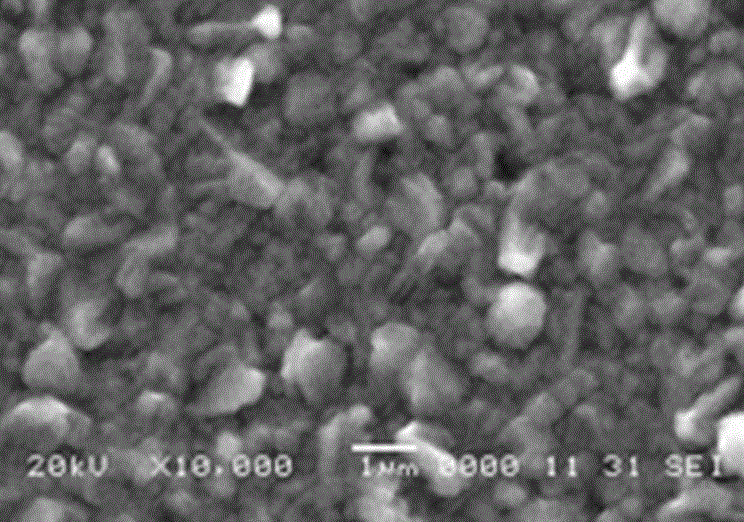

Image

Examples

Embodiment 1

[0025] The distribution ratio of the electroplating copper solution is as follows:

[0026] Copper sulfate: 80g / L

[0027] Sulfuric acid: 150g / L

[0028] Chloride ion concentration: 40ppm

[0029] Sodium dipentyl succinate: 5g / L

[0030] Sodium polydisulfide dipropane sulfonate: 5ppm

[0031] The copper electroplating solution configured according to the above components is repeatedly filtered and then stirred by air, and the circulation of the copper electroplating solution is continuously maintained during the electroplating process.

Embodiment 2

[0033] The distribution ratio of the electroplating copper solution is as follows:

[0034] Copper sulfate: 90g / L

[0035] Sulfuric acid: 160g / L

[0036] Chloride ion concentration: 45ppm

[0037] Sodium dipentyl succinate: 5.5g / L

[0038] Sodium thiazoline propane sulfonate: 5.5ppm

[0039] The copper electroplating solution configured according to the above components is repeatedly filtered and then stirred by air, and the circulation of the copper electroplating solution is continuously maintained during the electroplating process.

Embodiment 3

[0041] The distribution ratio of the electroplating copper solution is as follows:

[0042] Copper sulfate: 100g / L

[0043] Sulfuric acid: 170g / L

[0044] Chloride ion concentration: 50ppm

[0045] Sodium dihexyl sulfonate: 6g / L

[0046] Sodium thiazoline propane sulfonate: 6ppm

[0047] The copper electroplating solution configured according to the above components is repeatedly filtered and then stirred by air, and the circulation of the copper electroplating solution is continuously maintained during the electroplating process.

[0048] Of course, the copper electroplating solution provided by the present invention can add other auxiliary additives on the basis of the formula, only to re-optimize the content of the present invention, and it is also within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com