Matt black plasticized ink

A kind of ink, environmental protection technology, applied in the field of printing ink, can solve the problem of ink use restriction, etc., achieve the effect of reducing surface tension, reducing dispersion time, and good film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

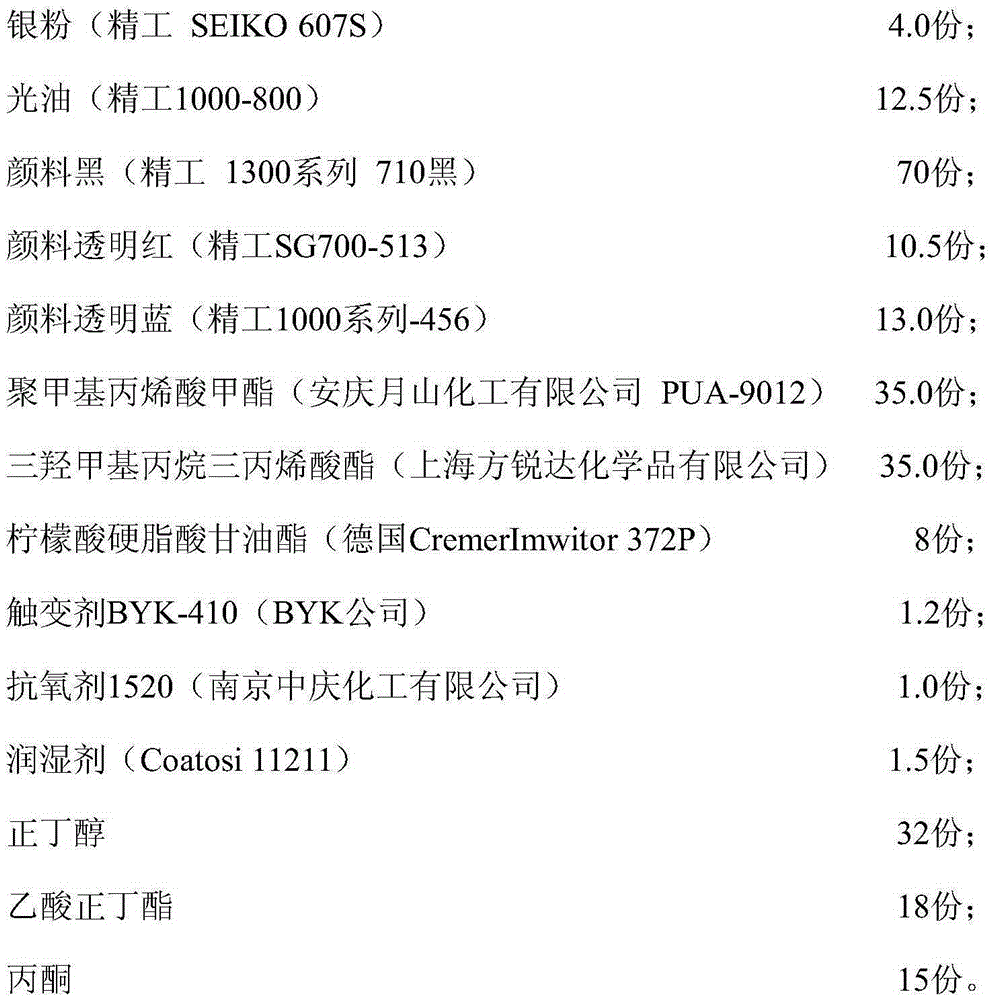

[0026] The matte black environmentally friendly plasticizing ink described in this embodiment contains the following components by weight:

[0027]

[0028] The preparation method of the matt black environmentally friendly plasticizing ink in this embodiment includes the following steps:

[0029] (1) Mix 4.0 parts by weight of silver powder and 12.5 parts by weight of Seiko 1000-800 varnish uniformly to obtain a conditioning material;

[0030] (2) 35.0 parts by weight of trimethylolpropane triacrylate and 30 parts by weight of mixed solvent are thoroughly mixed and dissolved in a stirring manner to obtain a dispersion solution;

[0031] (3) 70 parts by weight of pigment black, 10.5 parts of pigment transparent red, 13.0 parts by weight of pigment transparent blue and the dispersion solution prepared in step (2) are thoroughly mixed and wetted by stirring to obtain the first mixture liquid;

[0032] (4) 35.0 parts by weight of polymethyl methacrylate and 35 parts by weight of mixed solv...

Embodiment 2

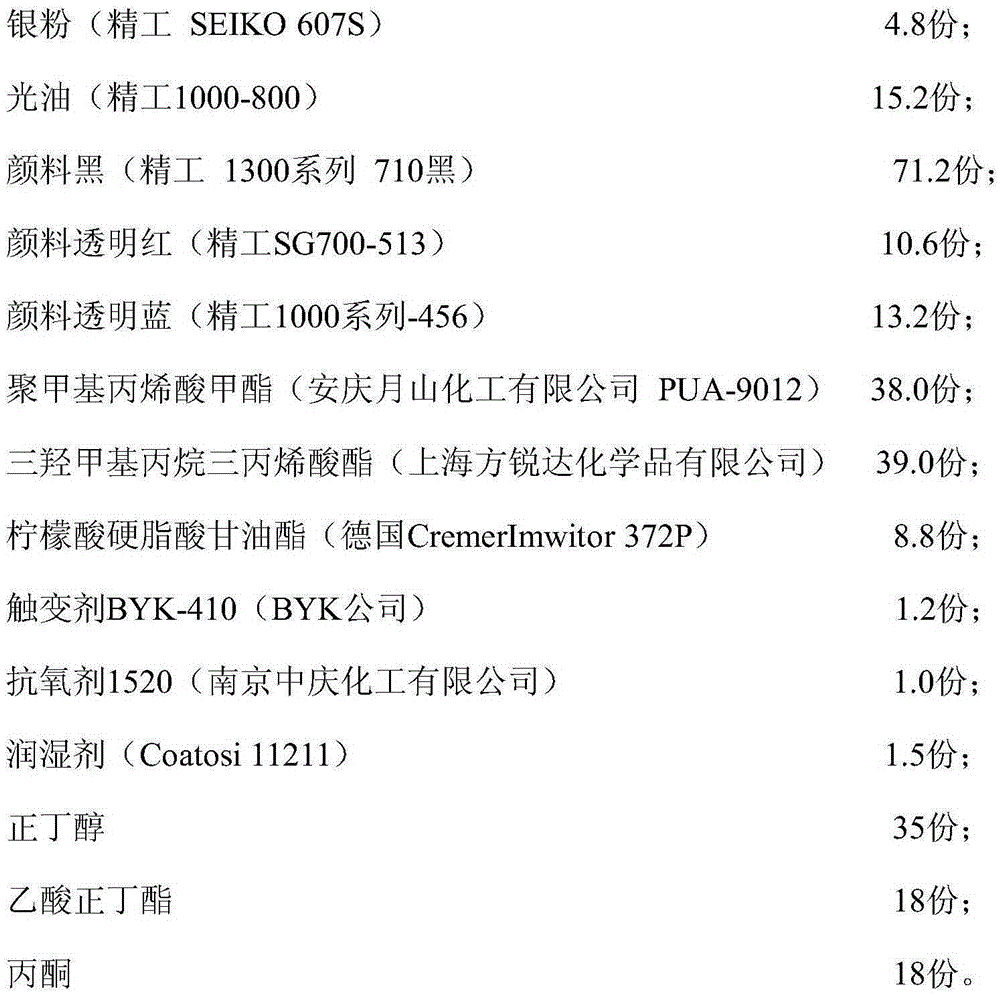

[0036] The matt black environmentally friendly plasticizing ink described in this embodiment contains the following components in parts by weight:

[0037]

[0038] The preparation method of the matt black environmentally friendly plasticizing ink described in this embodiment includes the following steps:

[0039] (1) 4.8 parts by weight of silver powder and 15.2 parts by weight of Seiko 1000-800 varnish are mixed uniformly to obtain a conditioning material;

[0040] (2) 39.0 parts by weight of trimethylolpropane triacrylate and 32 parts by weight of mixed solvent are thoroughly mixed and dissolved in a stirring manner to obtain a dispersion solution;

[0041] (3) 71.2 parts by weight of pigment black, 10.6 parts of pigment transparent red, 13.2 parts by weight of pigment transparent blue and the dispersion solution prepared in step (2) are thoroughly mixed and moistened by stirring to obtain the first mixture liquid;

[0042] (4) 38.0 parts by weight of polymethyl methacrylate and 39 ...

Embodiment 3

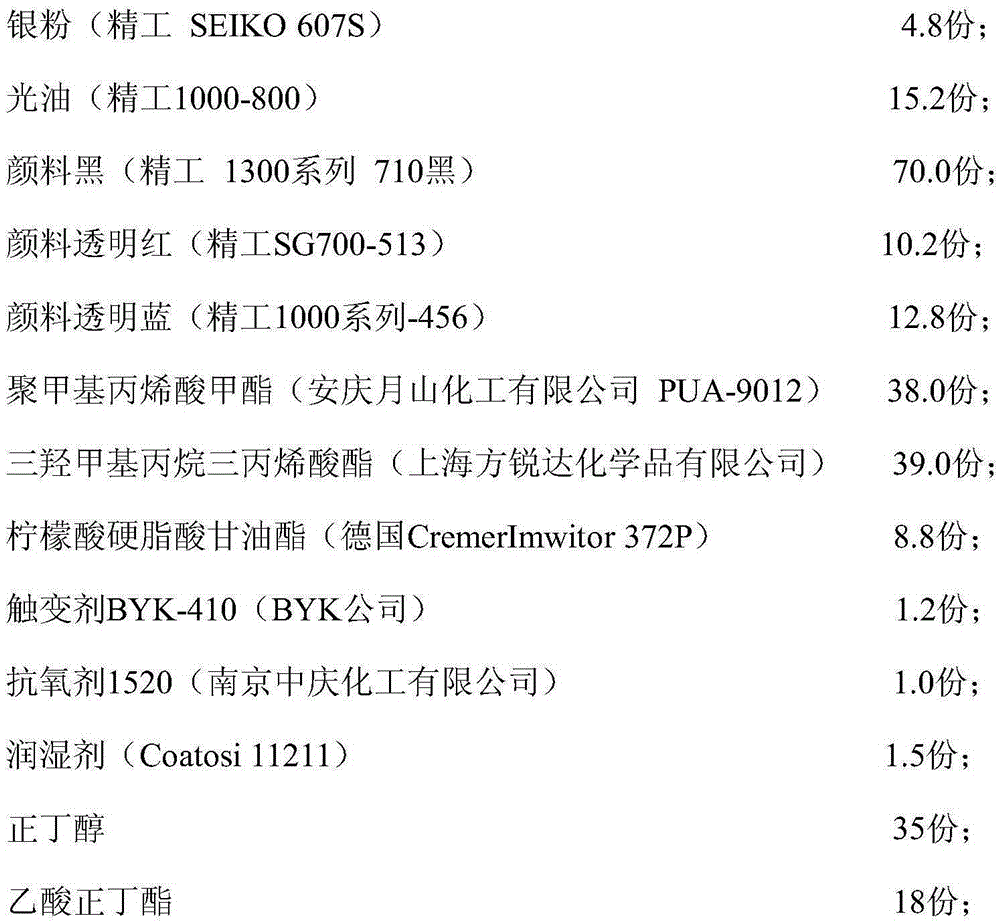

[0046] The matte black environmentally friendly plasticizing ink described in this embodiment contains the following components by weight:

[0047]

[0048]

[0049] The preparation method of the matt black environmentally friendly plasticizing ink in this embodiment includes the following steps:

[0050] (1) 4.8 parts by weight of silver powder and 15.2 parts by weight of Seiko 1000-800 varnish are mixed uniformly to obtain a conditioning material;

[0051] (2) 39.0 parts by weight of trimethylolpropane triacrylate and 32 parts by weight of mixed solvent are thoroughly mixed and dissolved in a stirring manner to obtain a dispersion solution;

[0052] (3) 70.0 parts by weight of pigment black, 10.2 parts of pigment transparent red, 12.8 parts by weight of pigment transparent blue and the dispersion solution prepared in step (2) are thoroughly mixed and moistened by stirring to obtain the first mixture liquid;

[0053] (4) 38.0 parts by weight of polymethyl methacrylate and 39 parts by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com