Cyanuric chloride-based quaternary ammonium salt compound and preparation method thereof

A technology of quaternary ammonium salt compound and cyanuric chloride, which is applied in the field of quaternary ammonium salt compound and its preparation, can solve the problem of not being able to graft onto the surface of materials, and achieve high charge density, cheap and easy-to-obtain raw materials, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

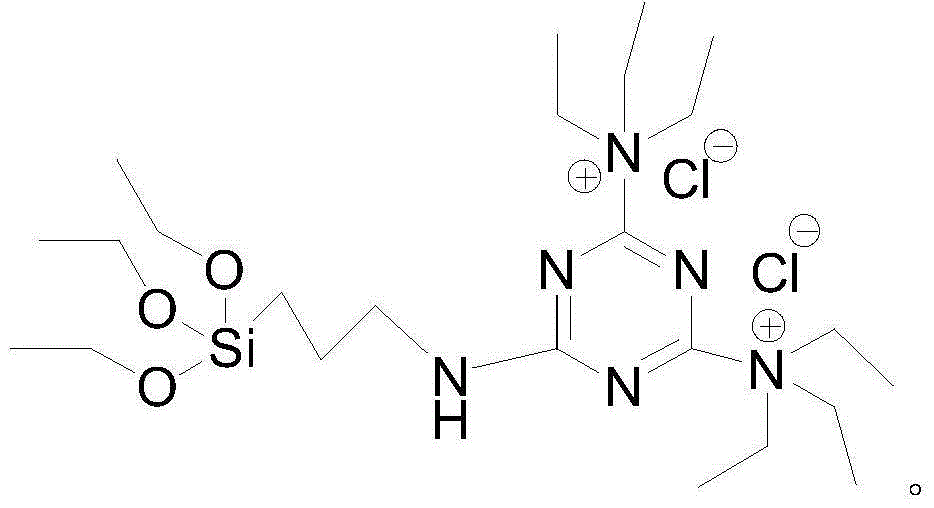

[0020] Accurately weigh 5.536g of cyanuric chloride and dissolve it in tetrahydrofuran with a volume of 100ml at a temperature of 0°C, and add 7ml of 3-aminopropyltriethoxysilane with a concentration of 98%, and stir for 3 hours. The chemical reaction formula as follows:

[0021]

[0022] Then the system was heated up to 30° C., stirred for 10 minutes, and then 10 ml of triethylamine with a concentration of 99% was added to react for 12 hours to obtain a light yellow suspension. The chemical reaction formula is as follows:

[0023]

[0024] The above light yellow suspension was centrifuged to obtain a light yellow solid, washed three times with tetrahydrofuran, and finally dried in vacuum at 80°C to obtain a quaternary ammonium compound based on cyanuric chloride,

[0025]

[0026] The product identification results are as follows:

[0027] to CDCl 3 The chemical shift (δ / ppm) of the hydrogen in the target product structure is as follows, 4.1~4.2 (1H, 6, singlet), ...

Embodiment 2

[0030] A kind of preparation method based on the quaternary ammonium salt compound of cyanuric chloride, replaces a chlorine on the cyanuric chloride with 3-aminopropyltriethoxysilane, reduces the activity of cyanuric chloride, and then with triethyl Amine reaction sloughs other two chlorines on cyanuric chloride and forms quaternary ammonium compound; Preparation method comprises the following steps:

[0031] (1) At 0°C, stir and react cyanuric chloride and 3-aminopropyltriethoxysilane in tetrahydrofuran for 5 hours, wherein, 3-aminopropyltriethoxysilane and cyanuric chloride The molar ratio is 0.8:1;

[0032] (2) Warm up the system obtained in step (1) to 25°C, stir for 15 minutes, then add triethylamine, the molar ratio of triethylamine to cyanuric chloride is 2:1, continue stirring for 8 hours to obtain light yellow suspension;

[0033] (3) Centrifuge the suspension obtained in step (2) to obtain a light yellow solid, wash it 3 times with tetrahydrofuran, and finally dry...

Embodiment 3

[0036] A kind of preparation method based on the quaternary ammonium salt compound of cyanuric chloride, replaces a chlorine on the cyanuric chloride with 3-aminopropyltriethoxysilane, reduces the activity of cyanuric chloride, and then with triethyl Amine reaction sloughs other two chlorines on cyanuric chloride and forms quaternary ammonium compound; Preparation method comprises the following steps:

[0037] (1) At 2°C, stir and react cyanuric chloride and 3-aminopropyltriethoxysilane in tetrahydrofuran for 4 hours, wherein the cyanuric chloride and cyanuric chloride The molar ratio is 1:1;

[0038] (2) Warm up the system obtained in step (1) to 35°C, stir for 12 minutes, then add triethylamine, the molar ratio of triethylamine to cyanuric chloride is 2.5:1, continue stirring for 10 hours to obtain light yellow suspension;

[0039] (3) Centrifuge the suspension obtained in step (2) to obtain a light yellow solid, wash it 4 times with tetrahydrofuran, and finally dry it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com