Potash feldspar utilization method

A technology for potassium feldspar and phosphate rock is applied in the field of utilization of ore resources, and can solve the problems of low potassium oxide content, difficult processing and utilization, and not being well developed and utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

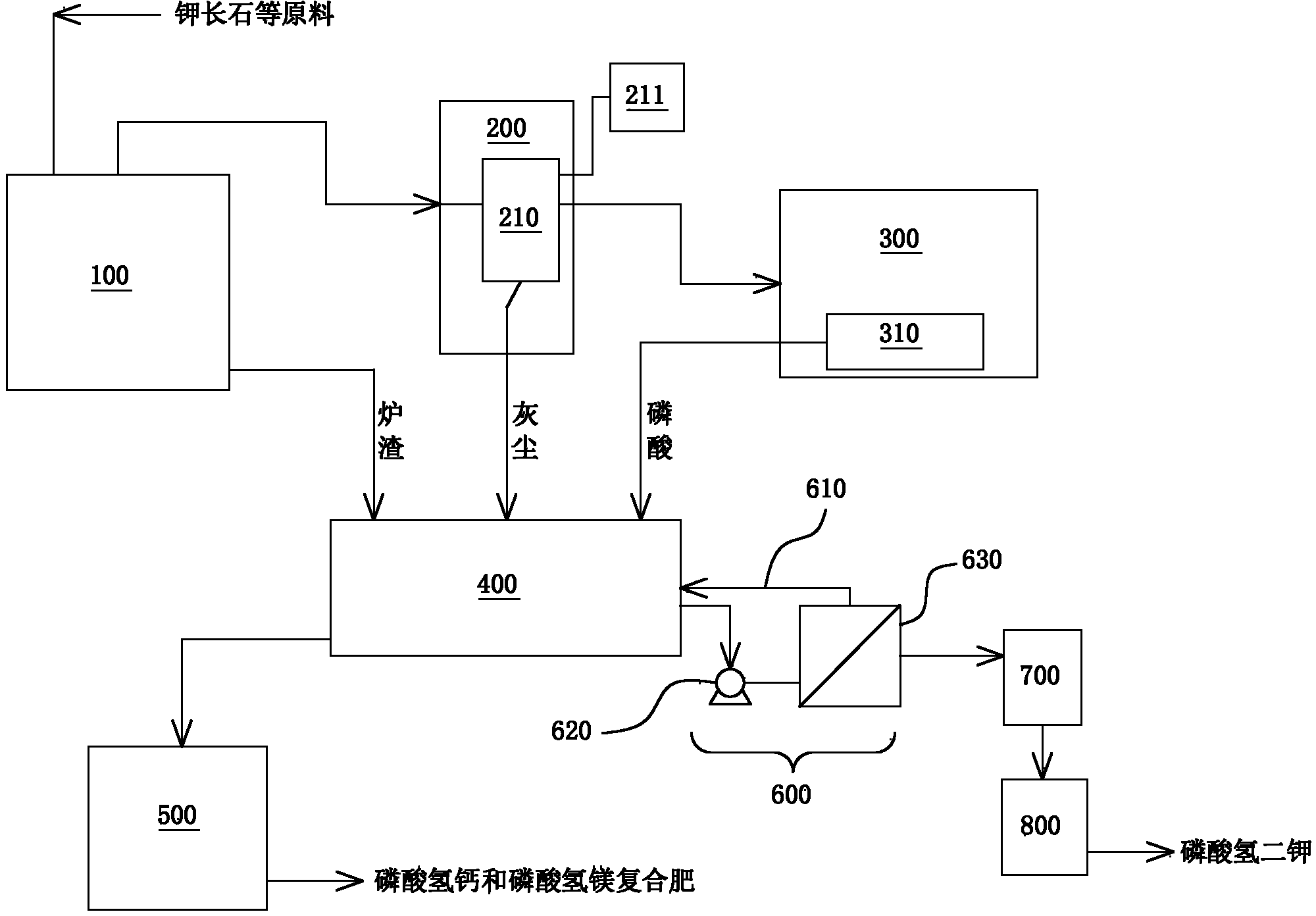

Image

Examples

Embodiment 1

[0011] Crushing potassium feldspar, phosphate rock, limestone, dolomite and coke, sieving particle size 3-35mm, according to potassium feldspar 18.3% (weight), phosphate rock 24.2% (weight), limestone 16.7% (weight), dolomite 16.6% (weight) of stone and 24.2% (weight) of coke are put into the electric furnace for reaction, and the weight percentage of phosphorus in phosphate rock is P 2 o 5 Calculated as about 20%, the weight percentage of potassium in potassium feldspar is expressed in K 2 O is calculated as about 15%, the electric furnace gas is controlled at 220-250°C for dust collection, the separated yellow phosphorus gas is used to produce phosphoric acid, and then the slag produced by the electric furnace 100, recovered potassium carbonate and produced phosphoric acid are stirred and mixed Reaction, the pH value of the liquid phase at the end of the reaction is controlled at 8.5-9, the temperature is controlled at 120-124 ° C, the liquid phase after the reaction is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com