A Modular Parallel Sorting System

A sorting system and modular technology, applied in the field of mechanical systems, can solve the problems of difficult site placement, merging and shunting multiple sub-lines, unreasonable utilization, etc., and achieve the effect of large storage capacity of cigarettes and less mutual influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following implementations are used to illustrate the present invention, but not to limit the scope of the present invention.

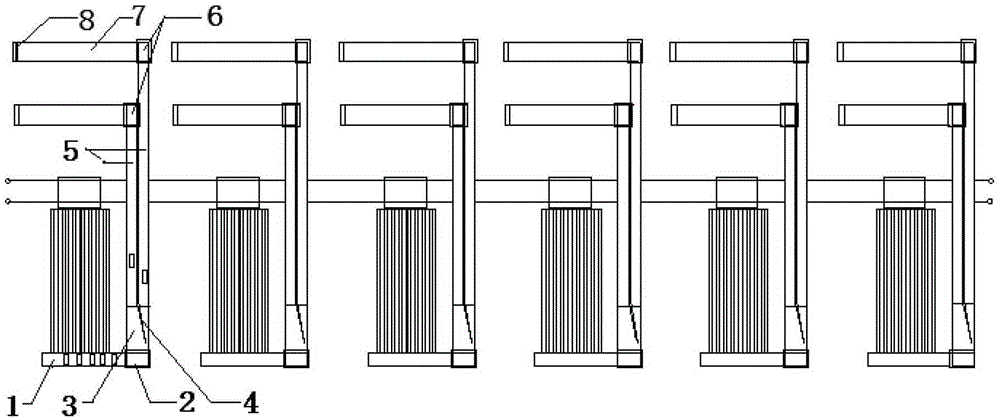

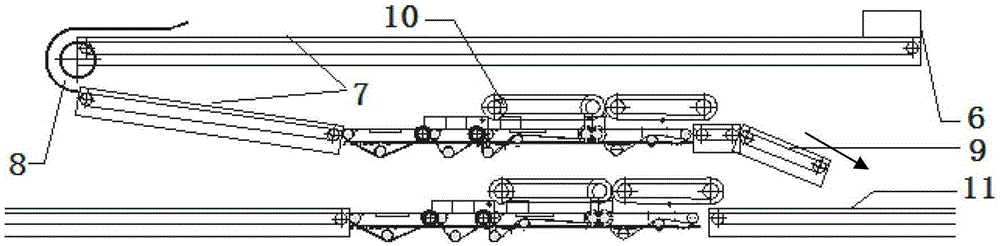

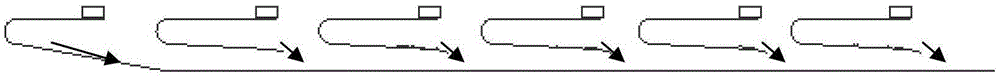

[0029] see Figure 1-5 , the present invention is a modularized parallel sorting system, which is composed of several parallel sorting line units, each sorting line unit includes: box smoke transport, box smoke unpacking, replenishment trolley, sorting unit, Cigarette conveying equipment (including vertical strike mechanism and vertical diversion mechanism), cigarette storage equipment (including horizontal strike mechanism, loopback mechanism, main buffer line belt, core number separation mechanism, and single-handling mechanism without swing arm). The specific sorting process is as follows:

[0030] 1. Box smoke conveying: through the roller line, the box smoke is transported to the corresponding sub-line according to the system requirements;

[0031] 2. Unpacking the box of cigarettes: responsible for opening the box of cigarettes and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com