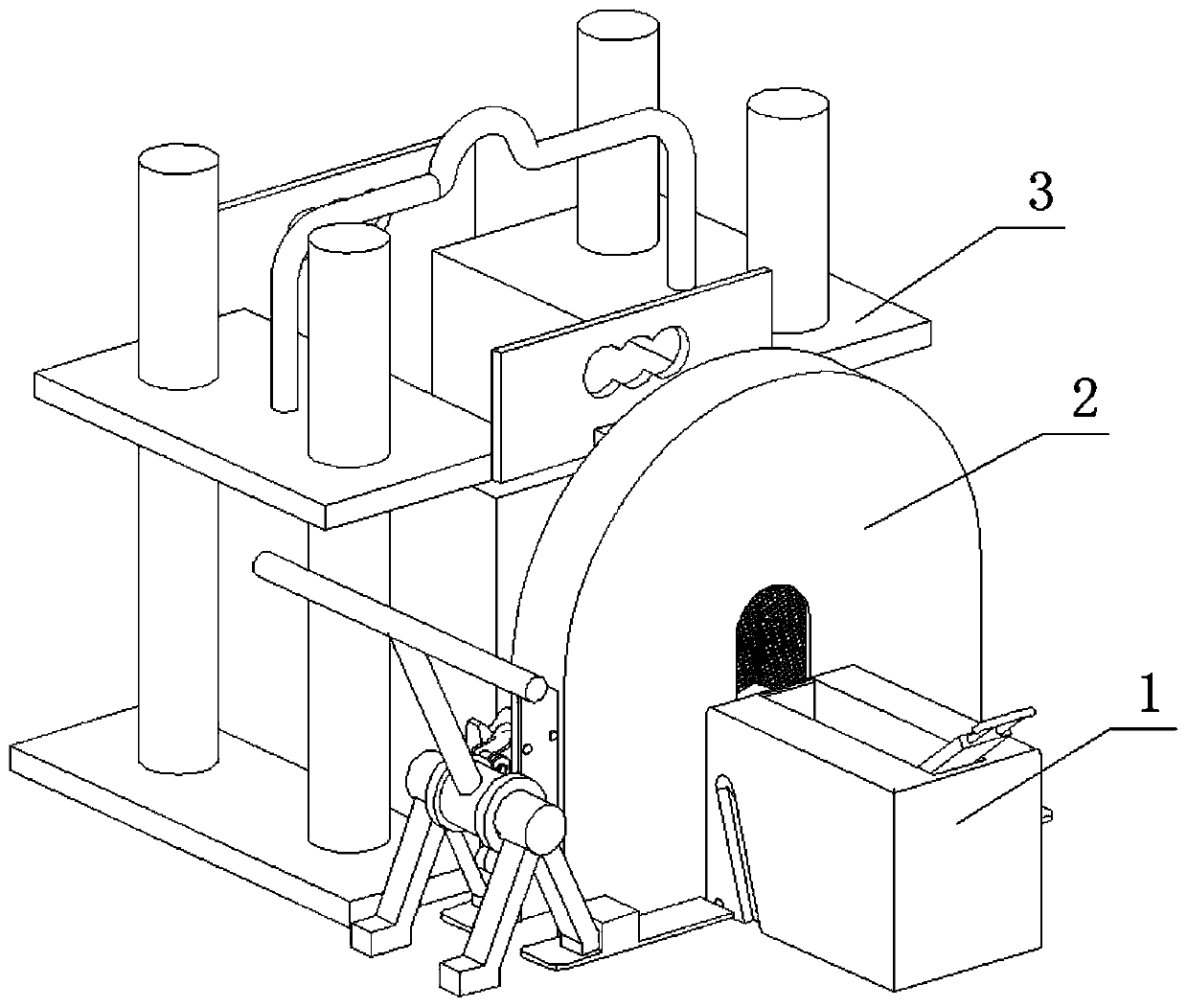

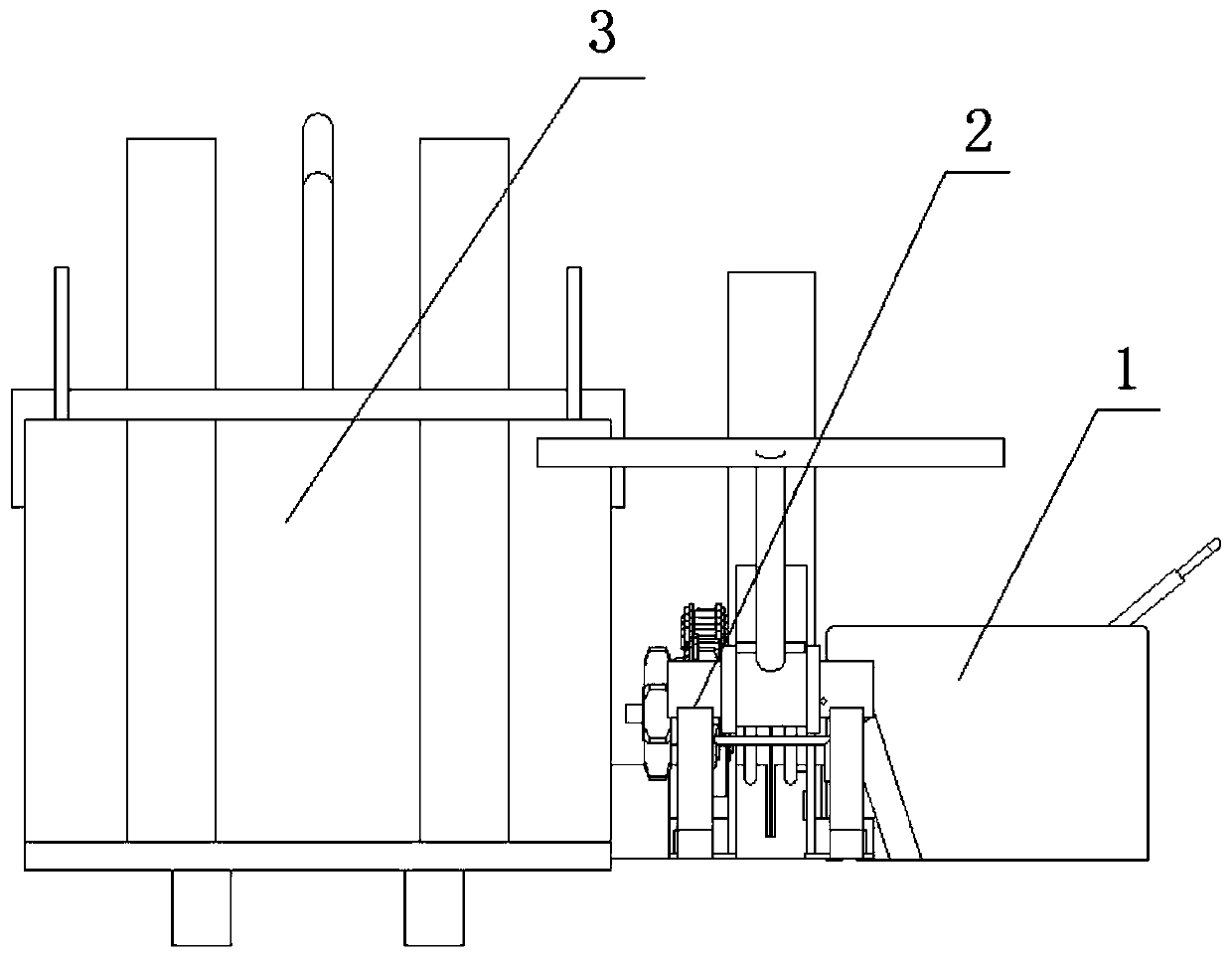

Metal rheological purification pressure forming equipment

A forming equipment, metal rheological technology, applied in the direction of magnetic separation, chemical instruments and methods, solid separation, etc., can solve problems such as rheological deformation involving defects, intergranular segregation, etc., to achieve simple operation, short process flow, The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

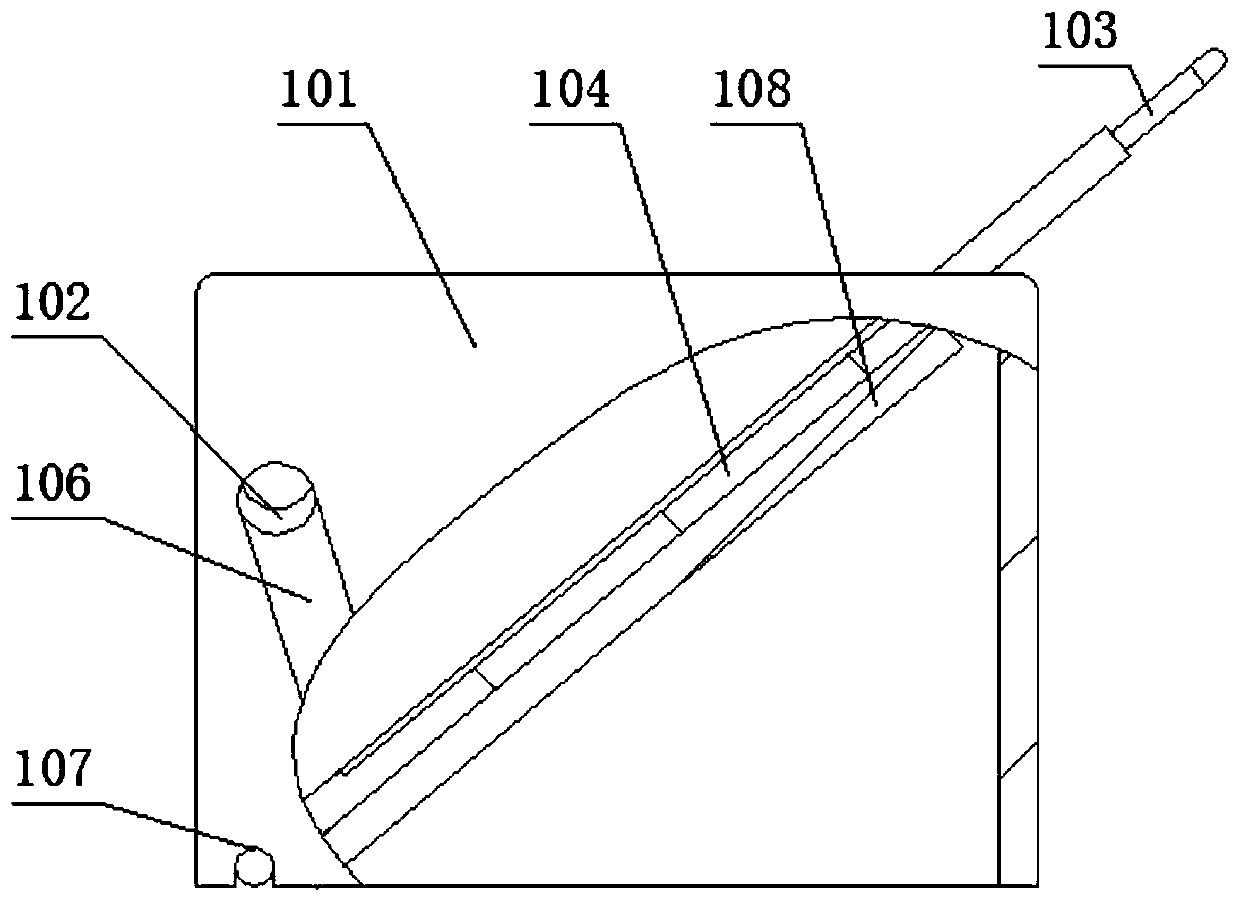

[0037] Taking A356 cast aluminum alloy as an example, the forming process of the metal rheological purification pressure forming equipment of the present invention is as follows: first, operate in the magnetic slag purification device 1, and pour the A356 melt onto the inclined runner 104 of the magnetic slag purification device 1 , the A356 melt flows along the inclined runner 104 to the outlet located at the bottom of the side wall of the box body 101, and under the magnetic force of the NdFeB permanent magnet plate 108, the magnetic slag in the A356 melt will be attracted to the inclined runner In the groove 105 on the surface of 104, the solid-liquid separation of the magnetic slag is completed. When the A356 melt is close to flow, the inclined runner 104 is lifted by the handle 103, and the remaining A356 melt flows to the direction of the discharge port until it is inclined The sprue 104 is close to the side wall where the outlet is located, and the excess A356 melt will ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com