Glass-reinforced-plastic counterweight protective guard for elevator and production process thereof

A production process, fiberglass technology, applied in the direction of layered products, synthetic resin layered products, lamination, etc., can solve the problems of poor working environment for workers, poor quality of hand lay-up molding, and short service life, and achieve the overall effect. Change, increase the service life, high overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

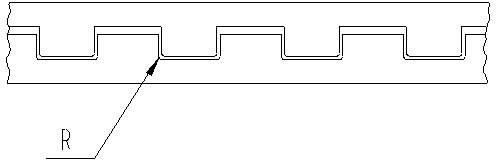

[0024] The invention provides a kind of FRP elevator counterweight guardrail, raw material comprises unsaturated resin 52%, glass fiber 38%, curing agent 4.7%, polyester film 0.3%, accelerator 2.5% and pigment 2.5% by weight percentage, wherein The middle layer is made of 52% unsaturated resin, 4.7% curing agent, 2.5% accelerator and 2.5% pigment mixed with 38% chopped glass fiber and heated and cured, and in the middle layer The two sides are respectively covered with polyester film, and the glass fiber reinforced plastic is provided with concave and convex longitudinal grooves alternately.

Embodiment 2

[0026] The invention provides a kind of FRP elevator counterweight guardrail, the raw material comprises 55% of unsaturated resin, 35% of glass fiber, 4.8% of curing agent, 0.2% of polyester film, 3% of accelerator and 2% of pigment by weight percentage, wherein The middle layer is made of 55% unsaturated resin, 4.8% curing agent, 3% accelerator and 2% pigment, adding 35% chopped glass fiber to the resin glue and heating and curing, and in the middle layer The two sides are respectively covered with polyester film, and the glass fiber reinforced plastic is provided with concave and convex longitudinal grooves alternately.

Embodiment 3

[0028] The invention provides a kind of FRP elevator counterweight guardrail. The raw materials include 58% unsaturated resin, 32% glass fiber, 4.9% curing agent, 0.1% polyester film, 3.5% accelerator and 1.5% pigment by weight percentage, wherein The middle layer is made of 58% unsaturated resin, 4.9% curing agent, 3.5% accelerator and 1.5% pigment mixed with 32% chopped glass fiber and heated and cured. The two sides are respectively covered with polyester film, and the glass fiber reinforced plastic is provided with concave and convex longitudinal grooves alternately.

[0029] A glass fiber reinforced plastic elevator counterweight guardrail of the present invention is mainly made of glass fiber, the resin and glass fiber are evenly distributed, resists cracking, and has a good sense of compactness for load-bearing parts. Eye-catching, high integrity, the surface is covered with a layer of anti-aging PET polyester film, which improves the service life, will not cause scratc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com