A gas shower head for a plasma reactor

A technology of plasma reactor and gas shower head is applied in the field of plasma treatment, which can solve the problems of uneven temperature distribution, uneven plasma treatment effect, deformation of temperature distribution devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

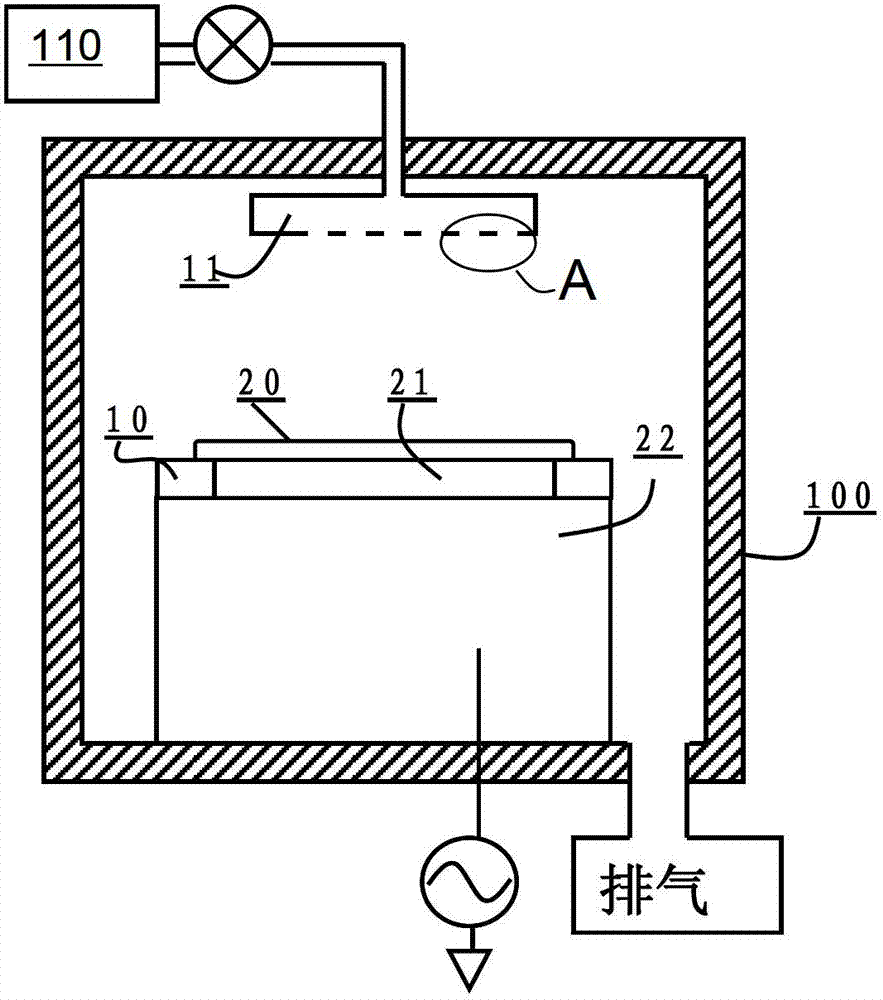

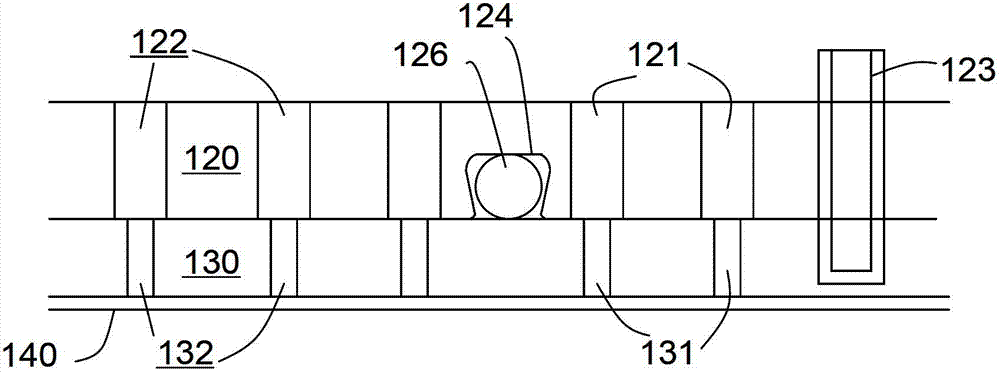

[0009] The following combination figure 1 with 2 , to describe the first embodiment of the present invention in detail.

[0010] Such as figure 1 As shown, the plasma reactor 100 of the present invention includes a base 22 on which the substrate 20 to be processed is fixed, and the gas shower head 11 is also used as an upper electrode opposite to the base 22 and fixed on the top of the reactor. The gas shower head 11 is connected to a gas source 110 through a gas pipeline. The base 22 includes a substrate holding device such as an electrostatic chuck 21 . An edge ring 10 surrounds the substrate 20 and the substrate holder 21 . At least one radio frequency power supply provides a radio frequency electric field to the lower electrode within the susceptor. The upper part of the gas shower head includes a gas distribution device, which divides the gas from the gas source into the first reaction gas and the second reaction gas, which are output to the rear end of the gas showe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com