Ultralow-emission power generation system using low-calorific-value fuel for combustion

A power generation system, low calorific value technology, applied in the direction of burning fuel in molten state, combustion method, combustion type, etc., can solve the problems of difficult dust emission, low combustion efficiency, low boiler efficiency, etc., to avoid low-temperature corrosion and dust accumulation, Optimize the working environment and improve the effect of dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

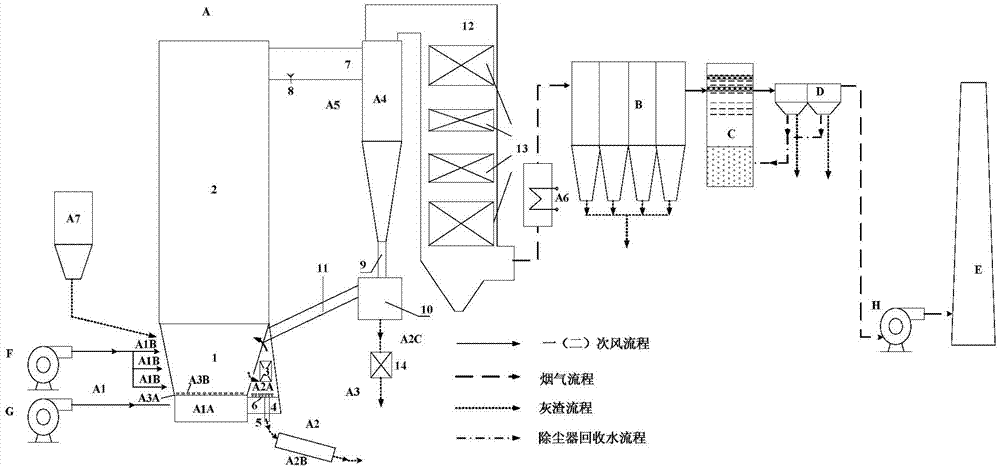

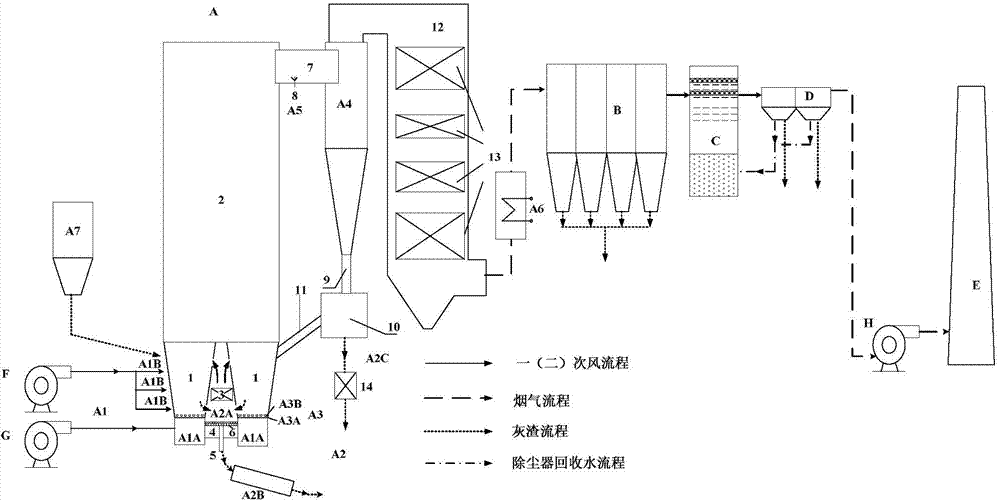

[0058] The attached picture shows a 300MW high-efficiency ultra-low-emission power generation system using low-calorific-value fuels. The boiler is a single-chamber structure, and there is only one set of low-resistance air distribution device A3. The boiler fuel is gangue with low calorific value of 8360kJ / kg (2000kCal / kg) as received. The gangue is sent to the high-temperature circulating fluidized bed boiler A for combustion. The combustion temperature is 1000°C. The air required for combustion is supplied by the controllable multi-stage air supply system A1. The ratio of primary air: secondary air is 4:6.

[0059] In this application example, the high-temperature flue gas generated by the high-temperature circulating fluidized bed boiler A is lowered to 90°C through the powerful flue gas cooler A6, and then enters the low-temperature dust collector B to remove most of the fly ash in the flue gas and send it to the wet process Flue gas desulfurization system C, the flue gas...

Embodiment 2

[0065] The attached picture shows a 330MW high-efficiency ultra-low emission power generation system using low calorific value fuel. The boiler has a double air distribution plate structure and is equipped with 2 sets of low resistance air distribution devices A3. The boiler fuel is gangue with low calorific value of 10450kJ / kg (2500kCal / kg) as received. The gangue is sent to the high-temperature circulating fluidized bed boiler A for combustion, the combustion temperature is 980°C, and the air required for combustion is supplied by the controllable multi-stage air supply system A1.

[0066] In this application example, the high-temperature flue gas generated by the high-temperature circulating fluidized bed boiler A is lowered to 80°C through the powerful flue gas cooler A6, and then enters the low-temperature dust collector B to remove most of the fly ash in the flue gas and send it to the wet process Flue gas desulfurization system C, deeply desulfurized SO 2 The concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com