Anti-radiation finishing processing method for fabric

A processing method and anti-radiation technology, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, fiber processing, etc., can solve the problems of metal fiber processing and use limitations, inapplicability, etc., and achieve good washing resistance , excellent cushioning, and excellent radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 1

[0045] Embodiment one, 1# fabric

[0046] 1. Preparation of materials

[0047] (1) Fabric: 26s TK / 1 jersey

[0048] (2) Nano-magnetic metal absorber: self-made nano-magnetic metal particles 1#

[0049] The preparation method of nano magnetic metal particles 1#: add 2g FeCl to 500mL 2 and 5gFeCl 3 , after fully dissolved, add NaOH solution dropwise at a constant speed under the action of a stirring bar, and when the pH value rises to 6-7, Fe will be generated 3 o 4 , filter the resulting precipitate, dry it, and finally make it into nanoparticles with an ultrasonic pulverizer.

[0050] (3) Polymer adhesive: Polyurethane adhesive LF-85 (Shanghai Lifeng Chemical Technology Co., Ltd.).

[0051] 2. Anti-radiation finishing process

[0052] The anti-radiation finishing process adopts the padding and baking process, and the fabric is dried and baked after padding the finishing solution, so that the nano-magnetic metal is attached to the fabric.

[0053] (1) Composition of wor...

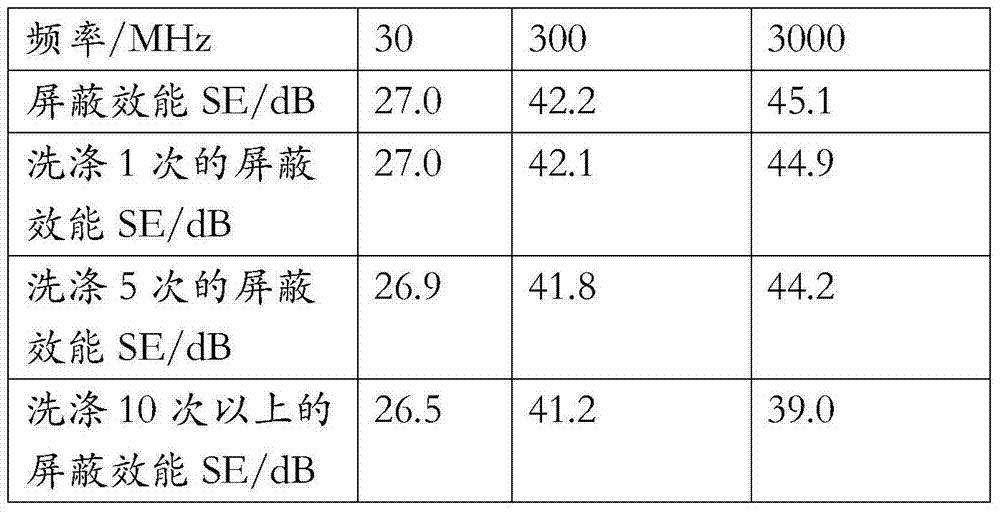

Embodiment 2 2

[0064] Embodiment two, 2# fabric:

[0065] 1. Preparation of materials

[0066] (1) Fabric: T / C50 / 50 polyester cotton jersey

[0067] (2) Nano-magnetic metal absorber: self-made nano-magnetic metal particles 1#

[0068] (3) Polymer adhesive: Polyurethane low-temperature adhesive (Shanghai Textile Research Institute)

[0069] 2. Anti-radiation finishing process

[0070] The anti-radiation finishing process adopts the padding and baking process, and the fabric is dried and baked after padding the finishing solution, so that the nano-magnetic metal is attached to the fabric.

[0071] (1) Composition of working fluid:

[0072] Nano magnetic metal wave absorber 60g / L

[0073] Polymer binder 60g / L

[0074] (2) Radiation protection finishing process curve

[0075] The fabric is dipped and rolled twice in the working solution → drying (90°C, 3min) → baking (140°C, 2min) → cooling

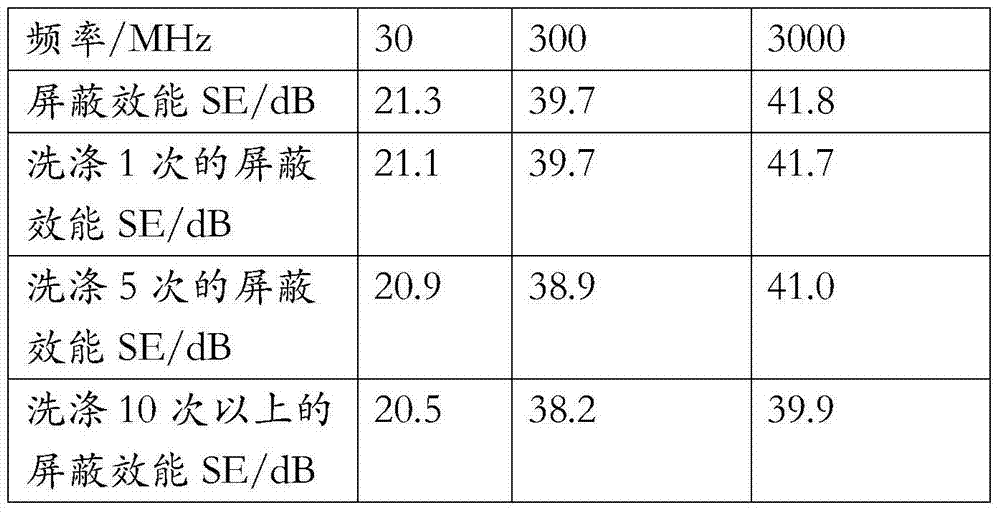

[0076] 3. Radiation protection performance test

[0077] According to GB / T23463-2009 "Protectiv...

Embodiment 3

[0082] Embodiment three, 3# fabric

[0083] 1. Preparation of materials

[0084] (1) Fabric: 150D pure polyester double-sided cloth

[0085] (2) Nano-magnetic metal absorber: self-made nano-magnetic metal particles 1#

[0086] (3) Polymer adhesive: Polyurethane adhesive Bilibai PU NEW (BASF).

[0087] 2. Anti-radiation finishing process

[0088] The anti-radiation finishing process adopts the padding and baking process, and the fabric is dried and baked after padding the finishing solution, so that the nano-magnetic metal is attached to the fabric.

[0089] (1) Composition of working fluid:

[0090] Nano magnetic metal absorber 30g / L

[0091] Polymer binder 40g / L

[0092] (2) Radiation protection finishing process curve

[0093] The fabric is dipped and rolled twice in the working solution → drying (90°C, 3min) → baking (145°C, 2min) → cooling

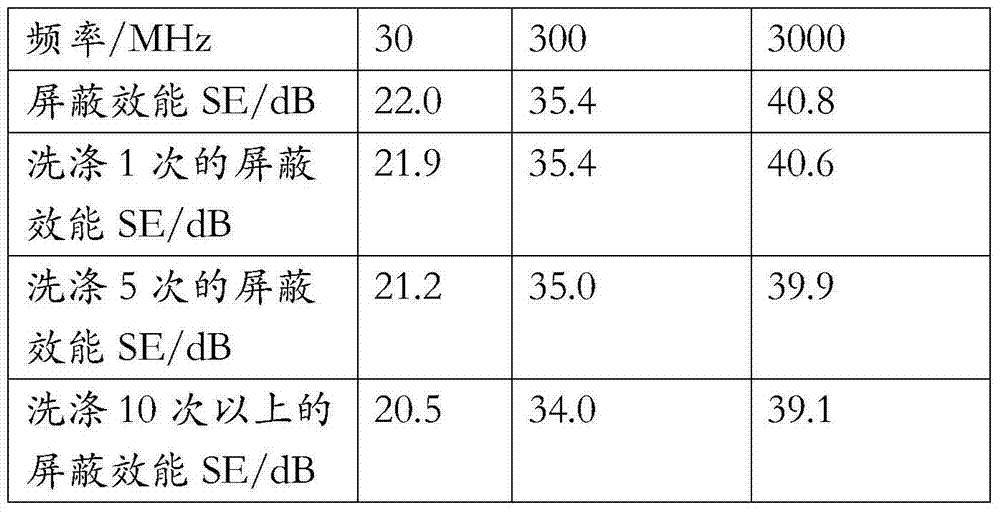

[0094] 3. Radiation protection performance test

[0095] According to GB / T23463-2009 "Protective Clothing Microwave Radiatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com