Method for comprehensive recovery of tantalum and niobium from red mud

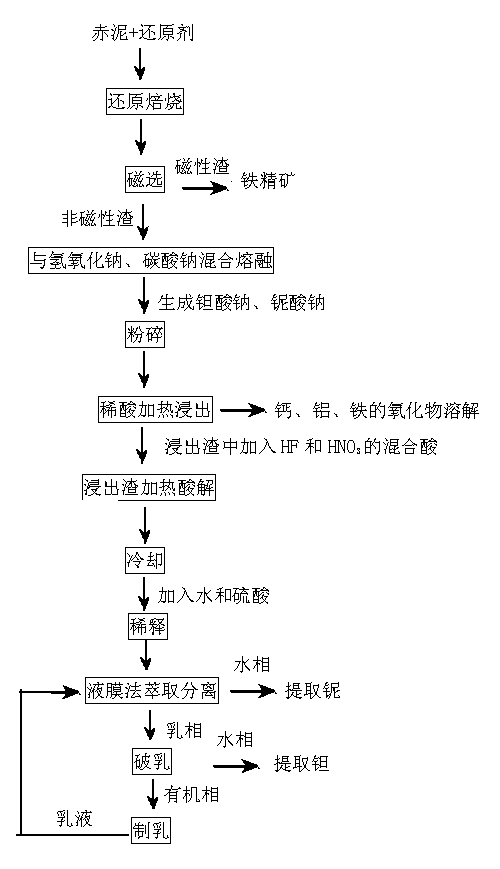

A technology for red mud, tantalum and niobium, which is applied in the field of extracting valuable metals, can solve the problems of recovering precious metals such as tantalum and niobium, which have not been reported, and achieve the effect of separation and extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Mix 60kg of red mud and 30kg of coal ash for reduction roasting to make Fe 2 o 3 converted to Fe 3 o 4 ; (2) Magnetic iron concentrate and non-magnetic slag are obtained by magnetic separation; (3) The mixture of non-magnetic slag, sodium hydroxide and sodium carbonate is melted at 500-800°C, and the mixing example of sodium hydroxide and sodium carbonate 9:1; (4) Crushing the molten massive melt, heating and stirring in 10% dilute hydrochloric acid for acidolysis leaching; (5) acid leaching residue in 21mol / L high concentration HF and HNO 3 Heating and dissolving in the mixed acid, after cooling, add water and H 2 SO 4 Dilute to get 6 mol / L H 2 SO 4 and 0.5 mol / L HF-containing niobium-tantalum feed solution; (6) liquid film method is used to separate and extract niobium-tantalum from the diluted solution, wherein the diluted solution is the feed liquid phase, and 2-octanol is the organic phase, 0.5mol / L NaOH is the internal liquid phase, the ratio of water t...

Embodiment 2

[0027] 1) Combine 50kg red mud with 10m 3 Coal gas is mixed for reduction roasting, so that Fe 2 o 3 converted to Fe 3 o 4 ; (2) Magnetic iron concentrate and non-magnetic slag are obtained by magnetic separation; (3) The mixture of non-magnetic slag, sodium hydroxide and sodium carbonate is melted at 500-800°C, and the mixing example of sodium hydroxide and sodium carbonate 8.5:1.5; (4) crush the melted massive melt, heat and stir in 20% dilute sulfuric acid for acidolysis leaching; (5) acid leaching residue in 22.5mol / L high concentration HF and HNO 3 Heating and dissolving in the mixed acid, after cooling, add water and H 2 SO 4 Dilute to get 5mol / L H 2 SO 4 and 0.4mol / L HF-containing niobium-tantalum feed solution; (6) liquid film method is used to separate and extract niobium-tantalum from the diluted solution, wherein the diluted solution is the feed liquid phase, and 2-octanol is the organic phase, 0.5mol / L NaOH internal liquid phase, the ratio of water to milk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com