Resin composition for base material of solar backboard

A technology of resin composition and solar back sheet, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of poor electrical insulation, easy embrittlement, poor shrinkage rate of modified polypropylene compositions, etc., and achieves a simple preparation method. The effect of easy operation, low water vapor transmission rate, excellent electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

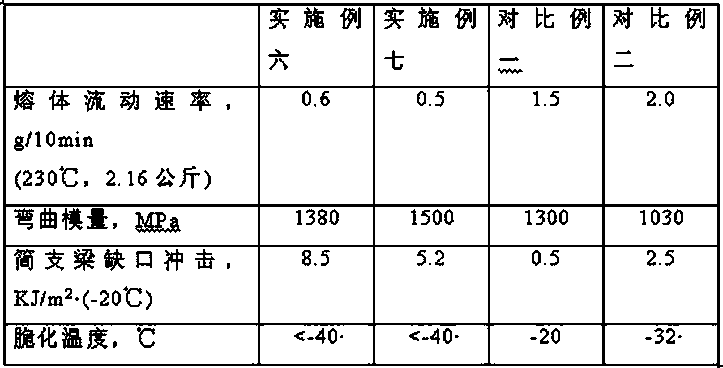

[0026] 75 parts (parts by weight) of block copolymer polypropylene K8303 (Beijing Yanshan Petrochemical Company, whose melt flow rate is 2.0 g / 10min at 230 °C / 2.16 kg) and 25 parts of high-density polyethylene 5000S (Beijing Yanshan Petrochemical Company, Its 190°C / 2.16kg melt flow rate is 0.8g / 10min) are measured separately and uniformly mixed, put into a twin-screw extruder for melt extrusion granulation;

[0027] The twin-screw adopts exhaust screw, the screw diameter is 75mm, the aspect ratio is 33, the screw temperature is controlled at 160~220°C, the screw speed is controlled at 100 rpm, and the residence time of the material in the screw is 2~4 minutes. After the material is cooled, granulated and dried, it becomes the finished resin composition S1. Its melt flow rate at 230°C / 2.16kg is 1.0g / 10min. The material performance test is shown in Table 1.

[0028] The block copolymer polypropylene K8303 is a block copolymer polypropylene produced by Beijing Yanshan Petrochemic...

Embodiment 2

[0031] 67 parts of block copolymerized polypropylene K8303 and 33 parts of high-pressure polyethylene 5000S were measured and uniformly mixed, and put into a twin-screw extruder for melt extrusion granulation. The twin-screw adopts exhaust screw, the screw diameter is 75mm, the aspect ratio is 33, the screw temperature is controlled at 160~220°C, the screw speed is controlled at 100 rpm, and the residence time of the material in the screw is 2~4 minutes. After the material is cooled, granulated and dried, it becomes the finished product S2. Its melt flow rate at 230°C / 2.16kg is 0.8g / 10min. The material performance test is shown in Table 1.

Embodiment 3

[0033] 50 parts of block copolymerized polypropylene K8303 and 50 parts of high-pressure polyethylene 5000S were measured and mixed uniformly, and put into a twin-screw extruder for melt extrusion granulation. The twin-screw adopts exhaust screw, the screw diameter is 75mm, the aspect ratio is 33, the screw temperature is controlled at 160~220°C, the screw speed is controlled at 100 rpm, and the residence time of the material in the screw is 2~4 minutes. After the material is cooled, granulated and dried, it becomes the finished product S3. Its melt flow rate at 230°C / 2.16kg is 0.9g / 10min. The material performance test is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com