Polysiloxane microsphere with core-shell structure and preparation method thereof

A technology of polysiloxane and core-shell structure, which is applied in the field of polysiloxane microspheres with core-shell structure and its preparation, and can solve the problems of poor diffusion effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

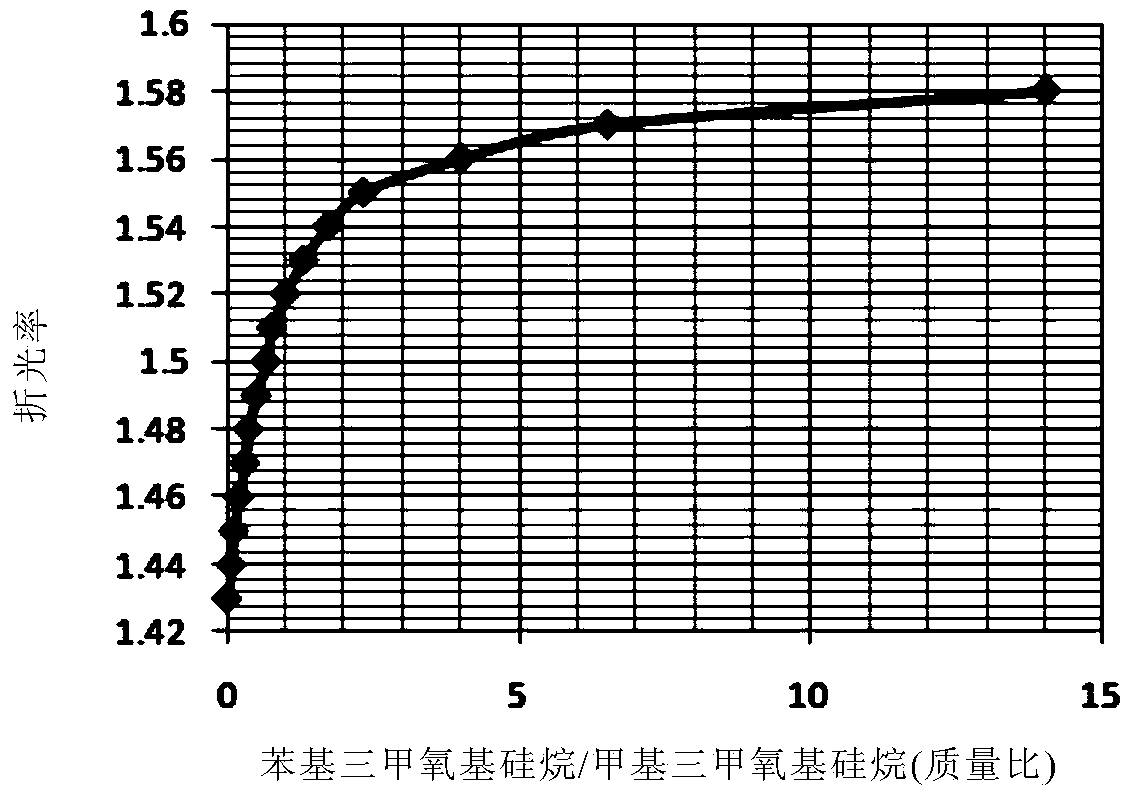

[0055] Preparation method of polysiloxane microspheres with core-shell structure

[0056] The polysiloxane microspheres with a core-shell structure of the present invention can be prepared according to conventional methods in the art, and can also be prepared according to the following method, the method comprising steps:

[0057] i) Firstly, the first-stage polymerization reaction is carried out to form the core of polysiloxane microspheres. At a certain temperature (such as 40-80°C or 50-70°C), in 100 parts by weight of alkaline aqueous solution, let 0.1-15 parts by weight (such as 0.1-10 parts by weight) of siloxane monomer (such as a silicon Oxane monomer or a mixture of multiple siloxane monomers) undergoes a polymerization reaction for a period of time (such as 0.5-5 hours or 0.5-2 hours) to obtain a core containing the polysiloxane microspheres. Therefore, the core of polysiloxane microspheres is obtained by polymerizing siloxane monomers in step (i).

[0058] ii) Nex...

Embodiment 1

[0098] Example 1 Preparation of polysiloxane microspheres with a core-shell structure with a core refractive index of 1.43 and a shell refractive index of 1.55

[0099] Take 300g of water, heat it to 65°C, add 14g of methyltrimethoxysilane, add 0.5mol / L NaOH solution under stirring, adjust the pH value to 9.6, and react for 1h to obtain a reaction mixture containing 1.4μm microspheres.

[0100] Under stirring, slowly add a mixed solution of 18.9g of phenyltrimethoxysilane and 8.1g of methyltrimethoxysilane dropwise to the above reaction mixture, react for 2h, filter under reduced pressure, wash with deionized water, and store at 300°C Dry in an oven for 2 hours to obtain polysiloxane microspheres with an average particle size of 2 μm and a core-shell structure. The particle size distribution is shown in figure 2 shown.

[0101] According to the identification of the refractive index, the core refractive index of the polysiloxane microsphere with the core-shell structure is ...

Embodiment 2

[0102] Example 2 Preparation of Polysiloxane Microspheres with Core-Shell Structure with Core Refractive Index of 1.49 and Shell Refractive Index of 1.52

[0103] Take 300g of water, heat it to 80°C, add a mixed solution of 2.7g of phenyltrimethoxysilane and 5.3g of methyltrimethoxysilane, add 0.5mol / L NaOH solution under stirring, adjust the pH value to 10.9, and react 0.5 h, A reaction mixture containing 0.25 μm microspheres was obtained.

[0104] Under stirring, slowly add a mixed solution of 28.5g of phenyltrimethoxysilane and 28.5g of methyltrimethoxysilane to the above reaction mixture dropwise, react for 2h, filter under reduced pressure, wash with deionized water, and directly in 300 °C in an oven for 2 hours to obtain polysiloxane microspheres with a core-shell structure and an average particle size of 0.5 μm.

[0105] It has been identified that the polysiloxane microspheres having a core-shell structure have a core refractive index of 1.49 and a shell refractive in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com