Safe and energy-saving high-purity sulfuric acid production device and operation method

A sulfuric acid production, energy-saving technology, applied in sulfur trioxide/sulfuric acid, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of unstable production, indeterminate boiling, and large entrainment of mist, etc. Achieve the effect of small volume and heat dissipation area, stable boiling process and small entrainment of mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

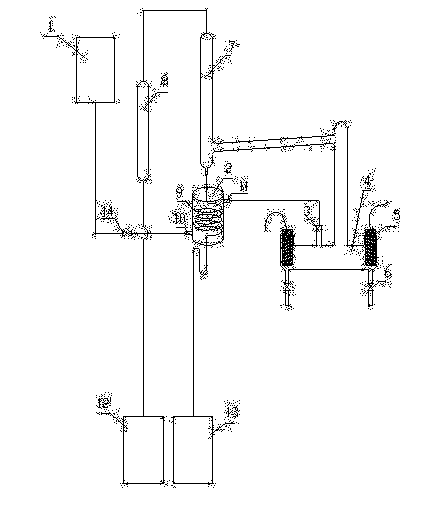

[0018] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

[0019] The principle of the present invention is: sulfuric acid is added to the heating kettle, the sulfuric acid itself acts as a conductor, and current is directly passed into the sulfuric acid. When the current passes through the sulfuric acid, the electrical energy is converted into heat energy, thereby generating heat in the sulfuric acid, causing the temperature of the sulfuric acid to rise , To achieve boiling and vaporization, without heating the wall, heat is generated inside the sulfuric acid, which is a real internal heating method. A detailed description is given below:

[0020] As shown in the drawings, the high-purity sulfuric acid production device of the present invention includes a high-level tank 1, a heat exchanger 2, a heating kettle 4, a rectification column 7, a condenser 8, a serpentine condenser 9, a low-boiling substance storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com