Catalyst carrier, preparation method thereof and heavy oil hydrogenation catalyst prepared therefrom

A catalyst carrier, non-oxidizing gas technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low catalytic activity, small specific surface area and pore capacity, etc., to achieve high reaction activity, The effect of high pore capacity and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

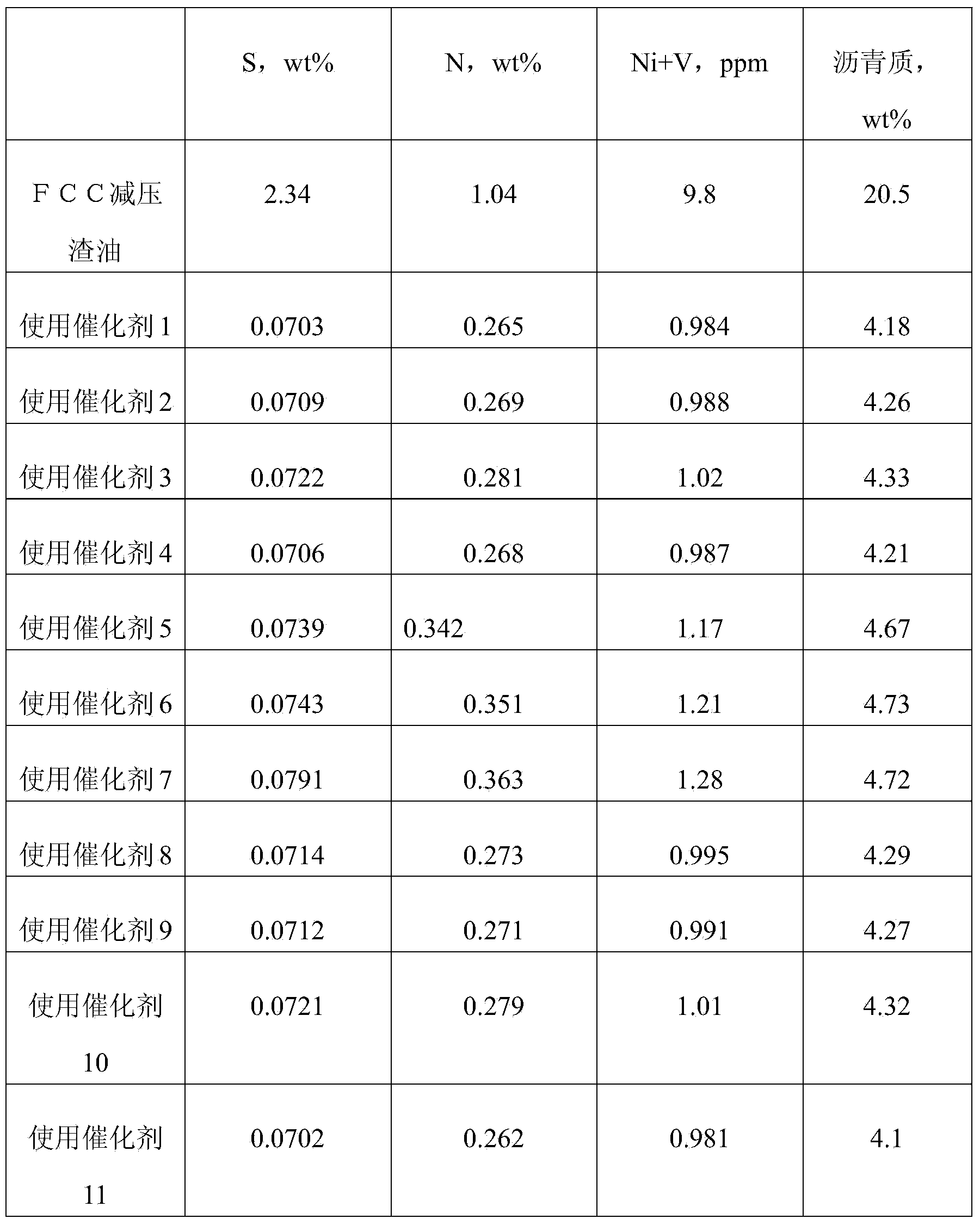

Embodiment 1

[0024] (1) Heat the coal tar pitch to 400°C for 12 hours in a pure nitrogen atmosphere at normal pressure to obtain mesophase pellets;

[0025] (2) Heating mesophase pellets to 900°C for 6 hours in a pure nitrogen atmosphere at normal pressure to obtain carrier 1;

[0026] (3) After immersing 100 g of carrier 1 in 1 L, 20 g / L ammonium molybdate solution for 4 hours, sintering at 450° C. for 8 hours to obtain catalyst 1 .

Embodiment 2

[0028] (1) Heat the coal tar pitch to 520°C for 1 hour in a pure nitrogen atmosphere at normal pressure to obtain mesophase pellets;

[0029] (2) The mesophase pellets were heated to 1300° C. for 0.5 h in a pure nitrogen atmosphere at normal pressure to obtain carrier 2;

[0030] (3) After immersing 100 g of carrier 2 in 1 L, 20 g / L ammonium molybdate solution for 4 hours, sintering at 450° C. for 8 hours to obtain catalyst 2 .

Embodiment 3

[0032] (1) Heat the coal tar pitch to 430°C for 9 hours in a pure nitrogen atmosphere at normal pressure to obtain mesophase pellets;

[0033] (2) Heating the mesophase pellets to 900°C for 5 hours in a pure nitrogen atmosphere at normal pressure to obtain the carrier 3;

[0034] (3) After impregnating 100 g of carrier 3 in 1 L, 20 g / L ammonium molybdate solution for 4 hours, sintering at 450° C. for 8 hours to obtain catalyst 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com