Three-layer medical infusion bag and manufacturing method thereof

An infusion bag and outer bag technology, which is applied in the field of medical infusion containers, can solve problems such as pollution, low safety, and high price, and achieve the effect of overcoming structural defects, high complexity requirements, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

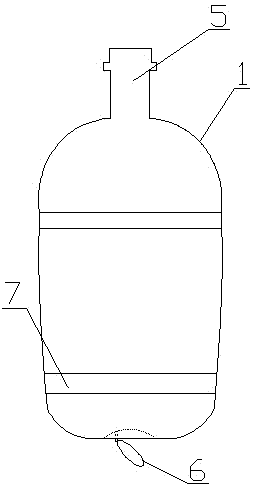

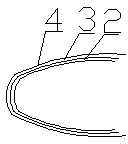

[0030] like figure 1 , 2As shown, the present embodiment provides a three-layer medical infusion bag, mainly an infusion bag body 1, the infusion bag body 1 is a flat shape, and the infusion bag body 1 is a three-layer structure, including an inner bag layer 2, a middle bag layer 3 and The outer bag layer 4; the inner bag layer 2 is a polyethylene material that is in contact with the liquid medicine, the middle bag layer 3 is a polypropylene and styrene-ethylene / butylene-styrene block copolymer material, and the outer bag layer 4 is that the layer in contact with the outside world is made of polypropylene, carboxylated styrene-ethylene / butylene-styrene block copolymer and anionic polymerized nylon nanocomposite blended layer materials; there is a bag opening in the middle of the top of the infusion bag body 1 5. There is a hanging hook 6 in the outer middle of the bottom of the infusion bag body 1 ; an elastic locking belt 7 is arranged on the outer peripheral surface of the ...

Embodiment 2

[0032] like figure 1 , 2 As shown, the present embodiment provides a three-layer medical infusion bag, mainly an infusion bag body 1, the infusion bag body 1 is a flat shape, and the infusion bag body 1 is a three-layer structure, including an inner bag layer 2, a middle bag layer 3 and The outer bag layer 4; the inner bag layer 2 is a polyethylene material that is in contact with the liquid medicine, the middle bag layer 3 is a polypropylene and styrene-ethylene / butylene-styrene block copolymer material, and the outer bag layer 4 is that the layer in contact with the outside world is made of polypropylene, carboxylated styrene-ethylene / butylene-styrene block copolymer and anionic polymerized nylon nanocomposite blended layer materials; there is a bag opening in the middle of the top of the infusion bag body 1 5. There is a hanging hook 6 in the outer middle of the bottom of the infusion bag body 1 ; an elastic locking belt 7 is arranged on the outer peripheral surface of the...

Embodiment 3

[0034] like figure 1 , 2 As shown, the present embodiment provides a three-layer medical infusion bag, mainly an infusion bag body 1, the infusion bag body 1 is a flat shape, and the infusion bag body 1 is a three-layer structure, including an inner bag layer 2, a middle bag layer 3 and The outer bag layer 4; the inner bag layer 2 is a polyethylene material that is in contact with the liquid medicine, the middle bag layer 3 is a polypropylene and styrene-ethylene / butylene-styrene block copolymer material, and the outer bag layer 4 is that the layer in contact with the outside world is made of polypropylene, carboxylated styrene-ethylene / butylene-styrene block copolymer and anionic polymerized nylon nanocomposite blended layer materials; there is a bag opening in the middle of the top of the infusion bag body 1 5. There is a hanging hook 6 in the outer middle of the bottom of the infusion bag body 1 ; an elastic locking belt 7 is arranged on the outer peripheral surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com