Crispy cereal biscuit and making technology thereof

A technology for crispy biscuits and miscellaneous grains, which is applied in the field of miscellaneous grains crispy biscuits and the production process thereof, can solve the problems of rough taste, complicated production process, dull color and the like, and achieves the effects of bright color, simple production process, and crisp and delicious taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

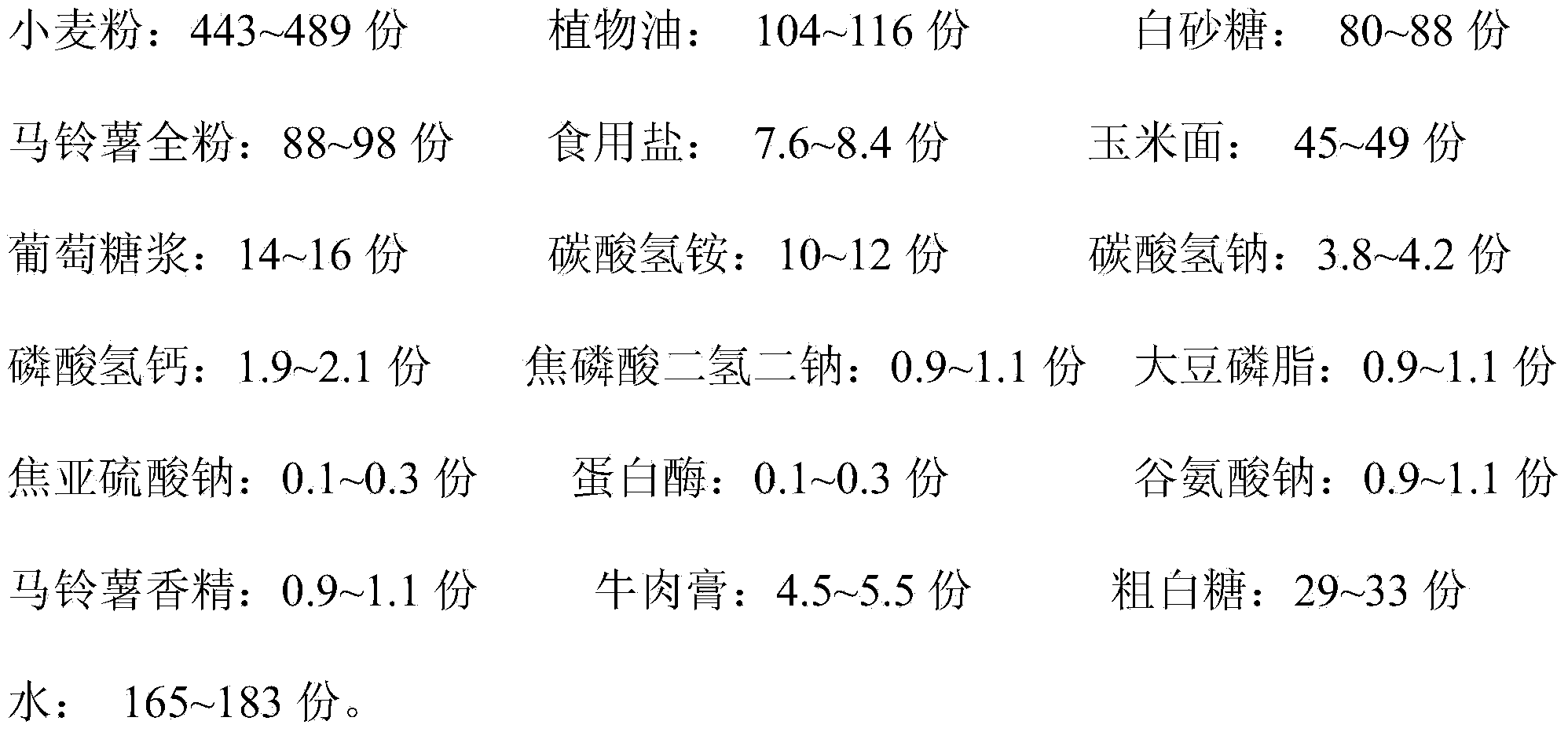

[0017] A kind of multigrain crisp biscuit in the present embodiment, it is made of the raw material of following weight portion:

[0018]

[0019] The manufacturing process of the above-mentioned multigrain crisp biscuits is made by the following steps:

[0020] ① Weigh 443 parts of wheat flour, 104 parts of vegetable oil, 80 parts of white sugar, 88 parts of whole potato flour, 7.6 parts of edible salt, 45 parts of cornmeal, 14 parts of glucose syrup, 10 parts of ammonium bicarbonate, 3.8 parts of sodium bicarbonate, hydrogen phosphate 1.9 parts of calcium, 0.9 parts of disodium dihydrogen pyrophosphate, 0.9 parts of soybean lecithin, 0.1 part of sodium metabisulfite, 0.1 part of protease, 0.9 parts of sodium glutamate, 0.9 parts of potato essence, 4.5 parts of beef extract, 29 parts of raw white sugar and water 165 copies;

[0021] ② Add 0.9 parts of soybean lecithin to 53 parts of vegetable oil and heat to melt for later use;

[0022] ③ Dissolve 0.1 part of sodium meta...

Embodiment 2

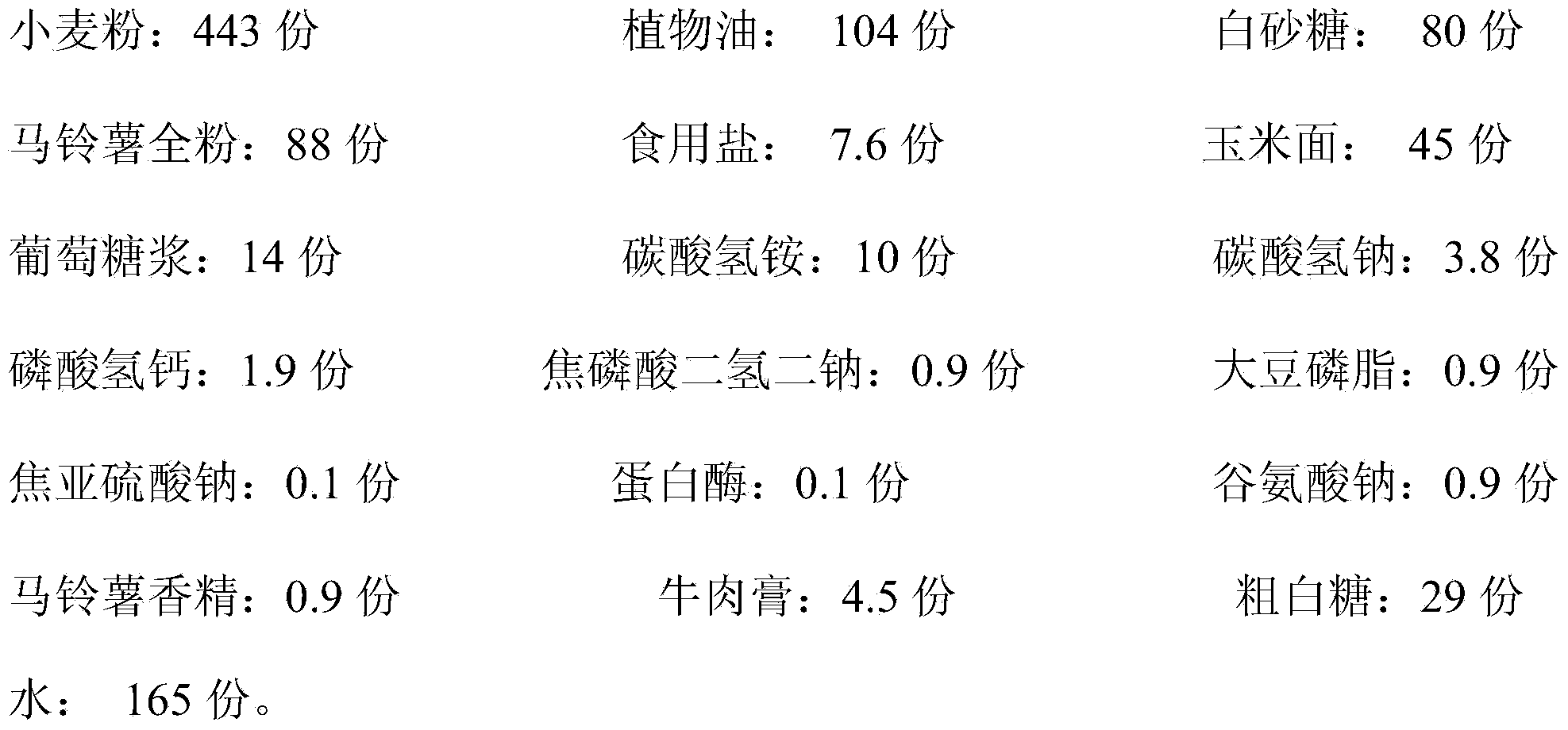

[0029] A kind of multigrain crisp biscuit in the present embodiment, it is made of the raw material of following weight portion:

[0030]

[0031]

[0032] The above-mentioned multigrain crisp biscuit manufacturing process is made by the following steps:

[0033] ① Weigh 489 parts of wheat flour, 116 parts of vegetable oil, 88 parts of white sugar, 98 parts of whole potato flour, 8.4 parts of edible salt, 49 parts of cornmeal, 16 parts of glucose syrup, 12 parts of ammonium bicarbonate, 4.2 parts of sodium bicarbonate, hydrogen phosphate 2.1 parts of calcium, 1.1 parts of disodium dihydrogen pyrophosphate, 1.1 parts of soybean lecithin, 0.3 parts of sodium pyrosulfite, 0.3 parts of protease, 1.1 parts of sodium glutamate, 1.1 parts of potato essence, 5.5 parts of beef extract, 33 parts of raw sugar and water 183 copies;

[0034] ② Add 1.1 parts of soybean lecithin to 59 parts of vegetable oil and heat to melt for later use;

[0035] ③Dissolve 0.3 part of sodium metabis...

Embodiment 3

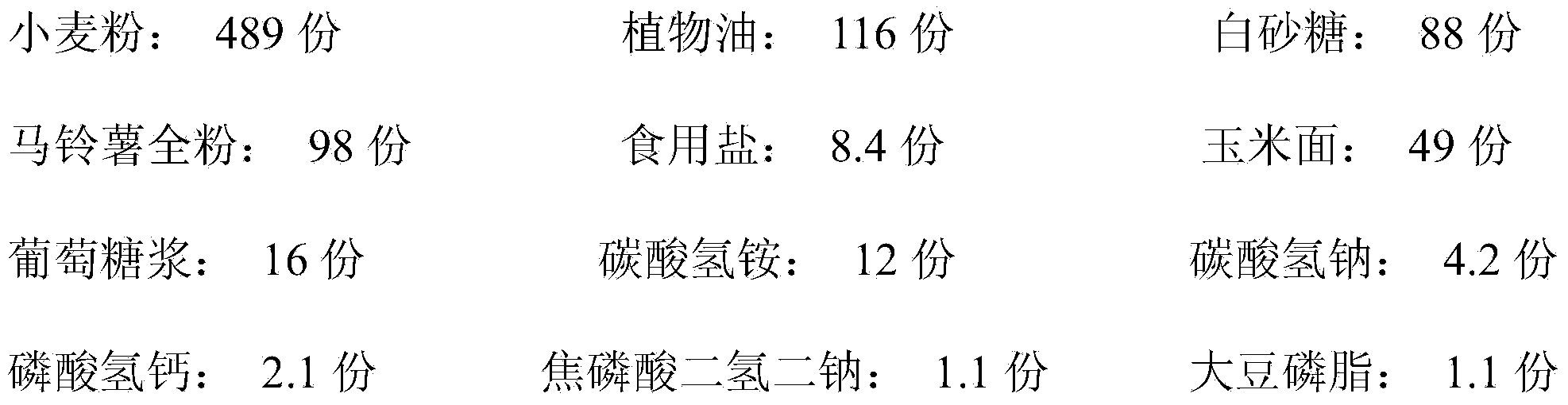

[0042] A kind of multigrain crisp biscuit in the present embodiment, it is made of the raw material of following weight portion:

[0043]

[0044] The manufacturing process of the above-mentioned multigrain crisp biscuits is made by the following steps:

[0045] ① Weigh 456 parts of wheat flour, 110 parts of vegetable oil, 85 parts of white sugar, 90 parts of whole potato flour, 8.1 parts of edible salt, 46 parts of cornmeal, 15 parts of glucose syrup, 11 parts of ammonium bicarbonate, 4 parts of sodium bicarbonate, hydrogen phosphate 2 parts of calcium, 1 part of disodium dihydrogen pyrophosphate, 1 part of soybean lecithin, 0.2 part of sodium pyrosulfite, 0.2 part of protease, 1 part of sodium glutamate, 1 part of potato essence, 5 parts of beef extract, 30 parts of raw white sugar and water 170 copies;

[0046] ② Add 1 part of soybean lecithin to 55 parts of vegetable oil and heat to melt for later use;

[0047] ③ Dissolve 0.2 part of sodium metabisulfite and 0.2 part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com