Adsorption and sound absorption structure of activated carbon board-wood composite overlaid with natural wood finish for indoor air quality, and preparation method thereof

A technology of wood materials and activated carbon plates, applied in gas treatment, building materials, separation methods, etc., can solve problems such as weak strength, and achieve the effects of convenient construction, excellent usability, and excellent handling operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

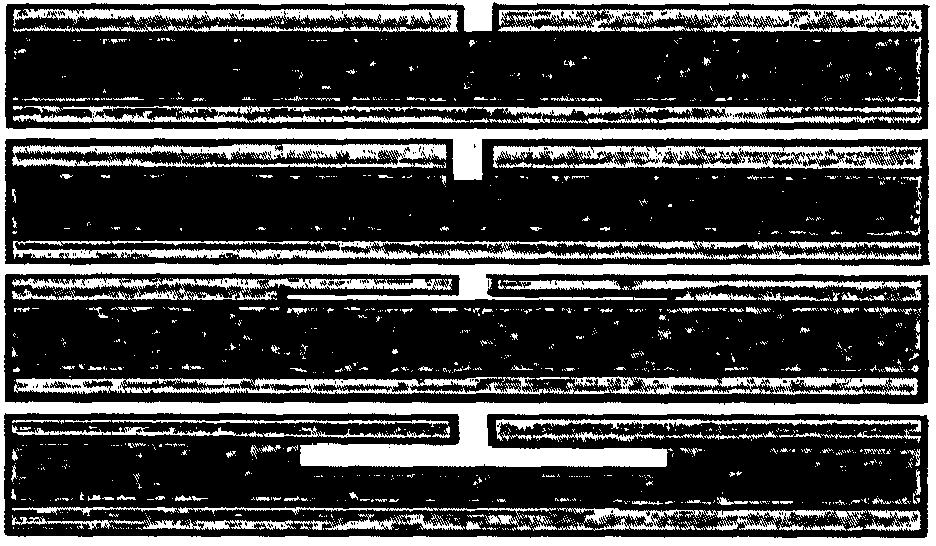

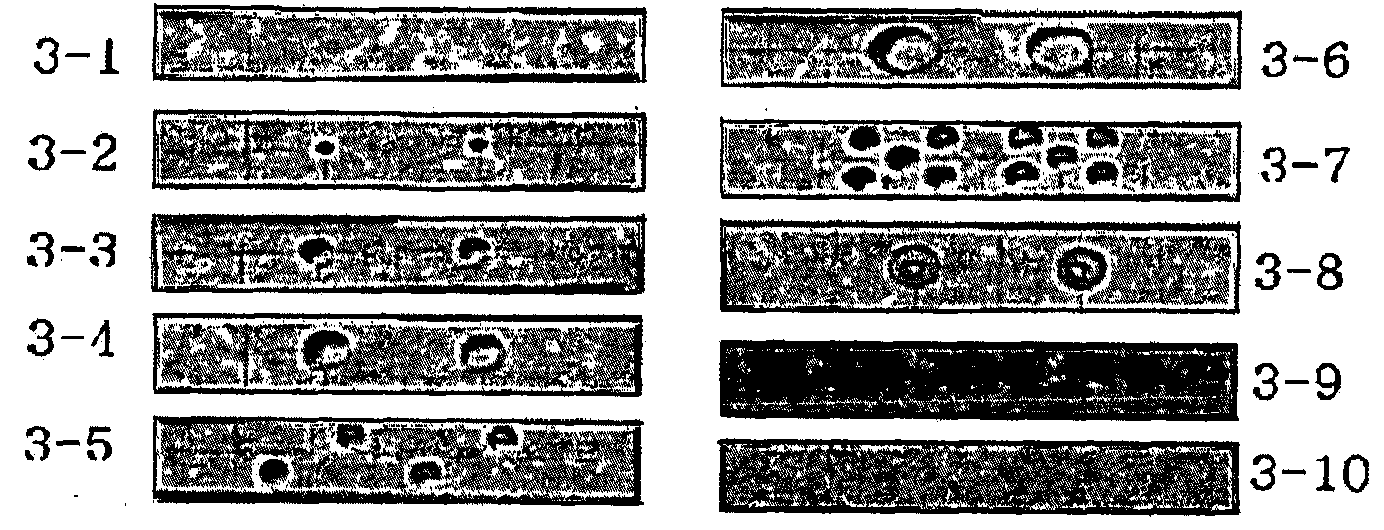

[0041] 1. Preferred embodiment of groove processing of decorative natural wood activated carbon plate wood material composite

[0042] like figure 1 As shown, in the activated carbon board wood material composite (manufacturing method example - the technique in the lower section of Table 1), the plywood covered with the decorative natural wood veneer as the surface board was grooved at regular intervals. For example, on the surface layer, a groove of 3mm width is processed every 19.7cm width, and its length is the same, thus, every 20cm width of the surface layer is implemented with a groove of 3mm. Therefore, the charcoal board wood material composite 1.5% of the total surface area corresponds to the groove area of linear grooving.

[0043] As shown in Table 1, the injection concentration of ethylene gas varies slightly at each injection, but when it reaches 20-26ppm, if 100% of the surface of the activated carbon plate directly leaks out of the air, 91% of the total gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com