Crystalline silicon solar cell matrix back electrode

A technology of solar cells and back electrodes, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of lower unit consumption and lower unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

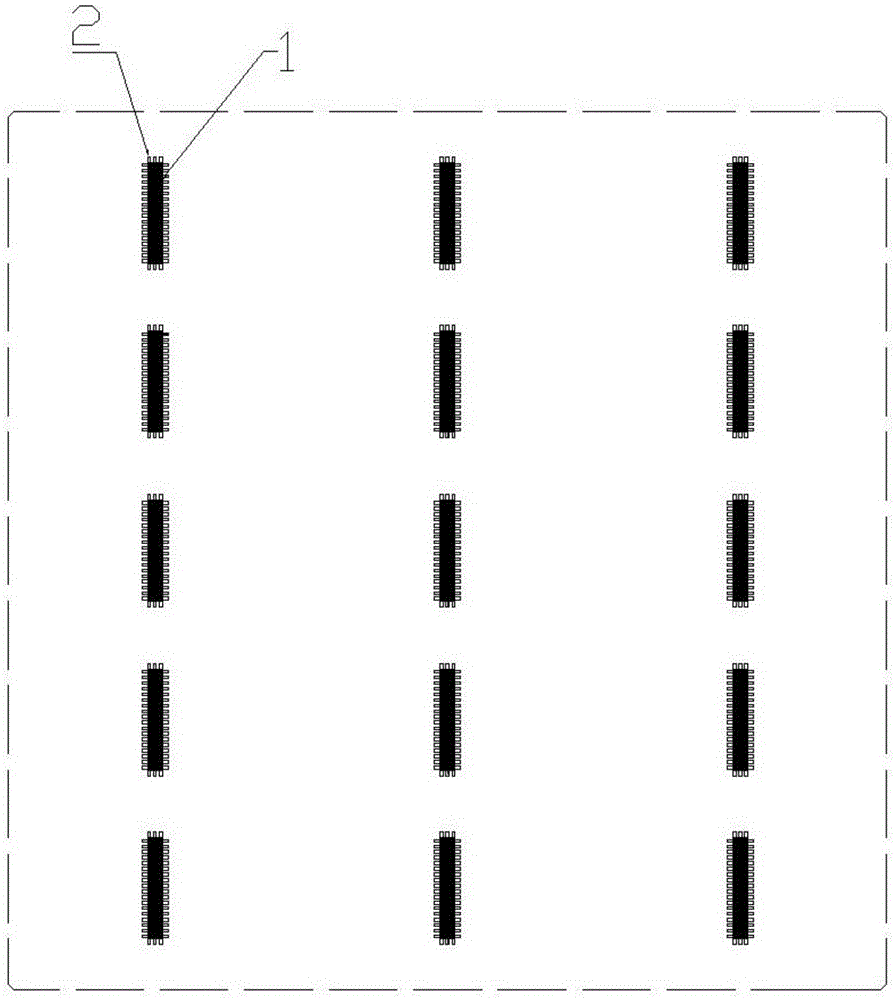

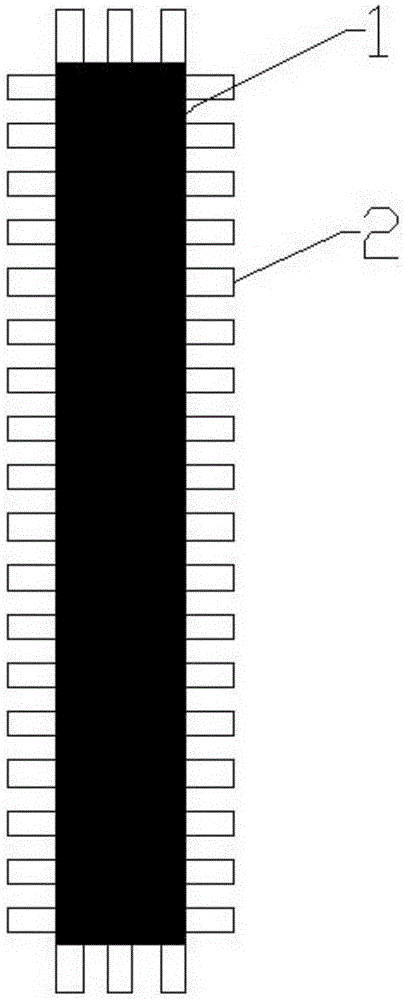

[0018] Embodiment: A matrix-type back electrode of a crystalline silicon solar cell, the crystalline silicon solar cell is a polycrystalline 156 solar cell, the back electrode 1 has fifteen segments, and the fifteen segment back electrodes are arranged in a matrix of five rows and three columns One row of back electrodes is located in the middle of the back of the cell, and the other two rows of back electrodes are each 52 mm away from the middle row of back electrodes (referring to the distance between the center lines of each row of back electrodes). A plurality of frame lines 2 are connected to the edges of the segment back electrodes, and the frame lines are evenly distributed around the back electrode at intervals, and the edges of the back electrodes and the frame lines are in contact with the back electric field.

[0019] The back electrodes in each segment are rectangular vertical strips with a length of 18 mm and a width of 2.3 mm, and the distance between the back ele...

experiment example

[0022] Experimental example: matrix back electrode of the present invention

[0023] Put the screen plate into the printing machine, install the scraper, ink return knife, and add slurry, adjust the printing parameters to ensure that the printed back electrode pattern is good, measure the wet weight, and the results are as follows:

[0024] sampling

1

2

3

4

5

average

wet weight (g)

0.033

0.035

0.037

0.036

0.034

0.035

[0025] The situation of measuring its electrical performance parameters under the conditions of AM1.5, light intensity 1000W, and 25°C is:

[0026] Voc (open circuit voltage)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com