Method for Detecting Bridge Defects at the Bottom of Polysilicon Using Small Window Pattern Test Structure

A technology for testing structures and small windows, which is applied in semiconductor/solid-state device testing/measurement, measurement devices, material analysis using wave/particle radiation, etc. It can solve the problem that polysilicon gate etching residual defects are not easy to be detected, etc. , to achieve the effects of shortening the R&D cycle, guaranteeing product yield, and shortening the impact interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

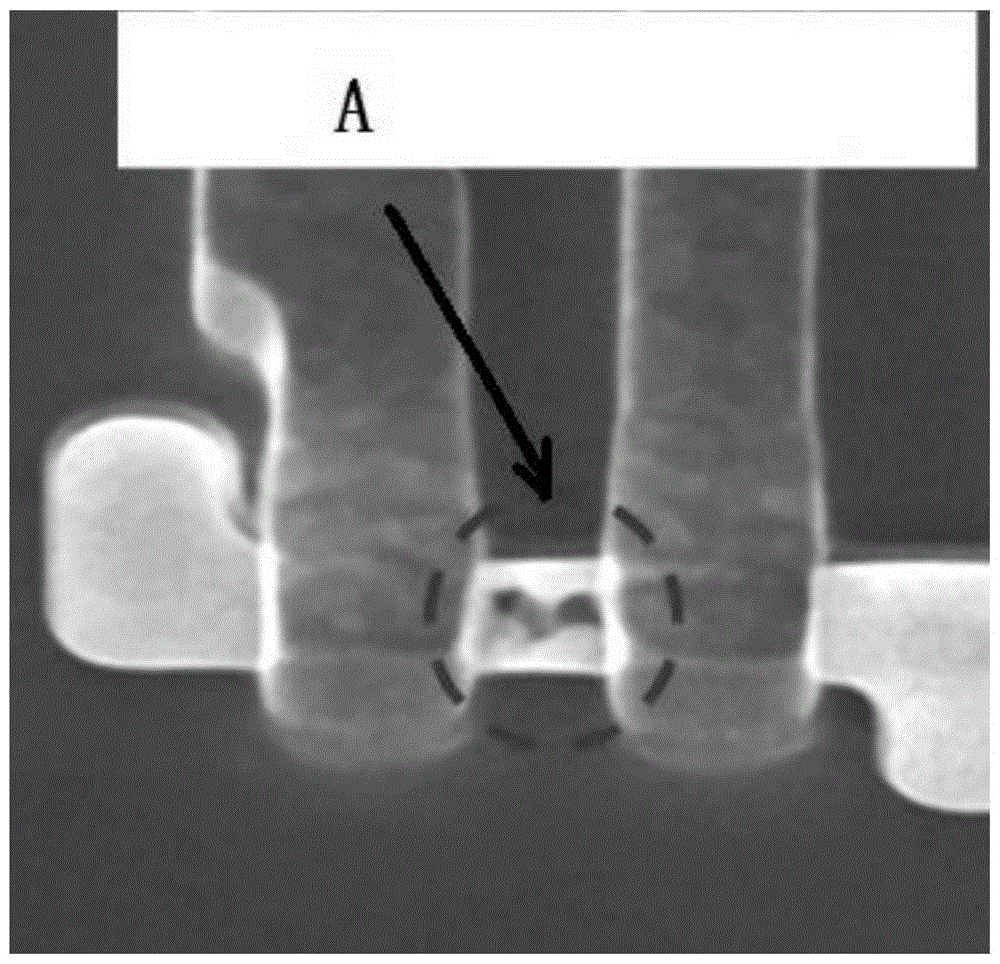

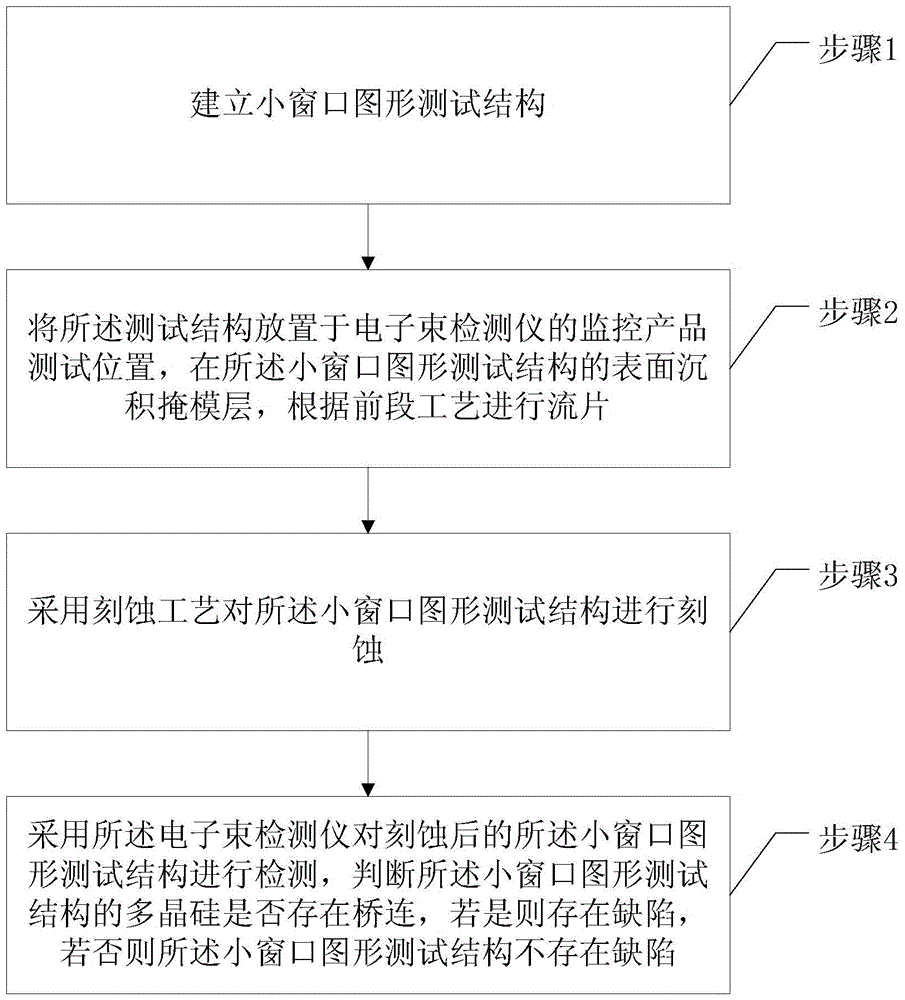

[0028] like figure 2 As shown, the present invention provides a method for detecting polysilicon bottom bridging 6 defects using a small window pattern test structure, comprising the following steps:

[0029] Take the 55nm logic product to establish a small window graphic test structure as an example:

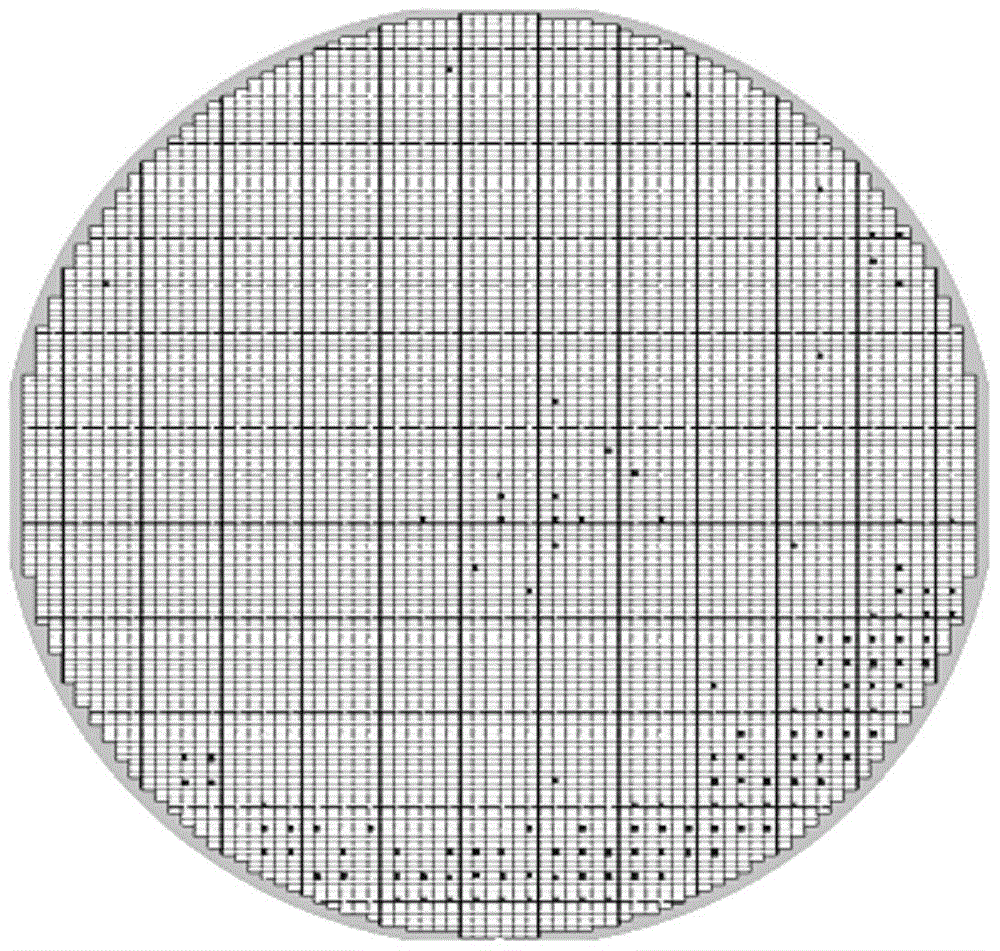

[0030] Step 1. Establish a small window pattern test structure (such as image 3 shown);

[0031] Step 2. Place the small window pattern test structure on the monitoring product test position of the electron beam detector, deposit a mask layer on the surface of the small window pattern test structure, and tape out according to the previous process;

[0032] Step 3. Etching the small window pattern test structure by an etching process;

[0033] Step 4. Adopt electron beam detector to detect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com