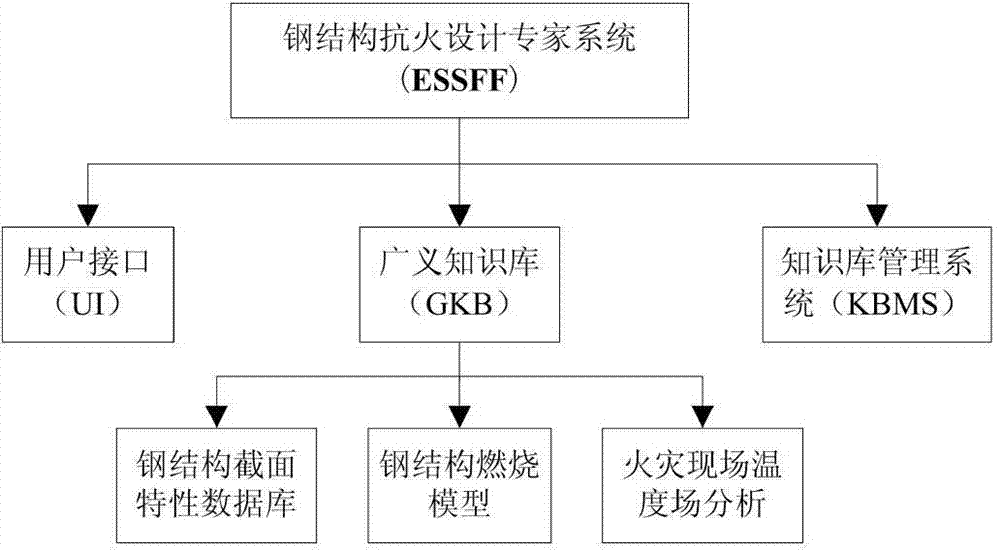

Steel structure fire resistance design method based on ESSFF

A technology of expert system and design method, applied in computing, special data processing applications, instruments, etc., can solve problems such as the lack of fire resistance design software, meet the requirements of fire resistance performance, strengthen and repair fire resistance performance, improve fire resistance The effect of fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

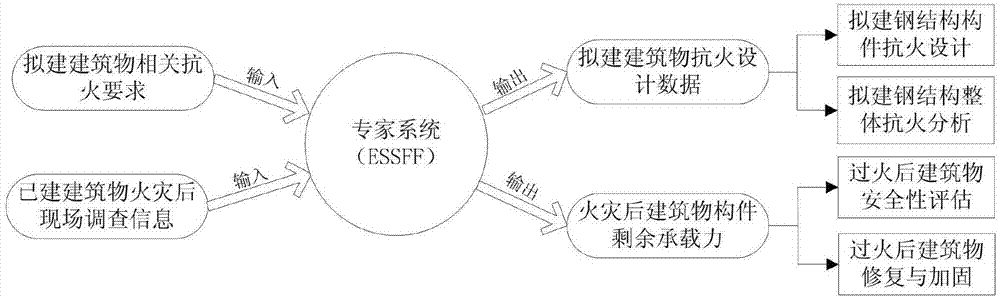

[0056] This embodiment introduces in detail the fire resistance design of the steel structure before the fire.

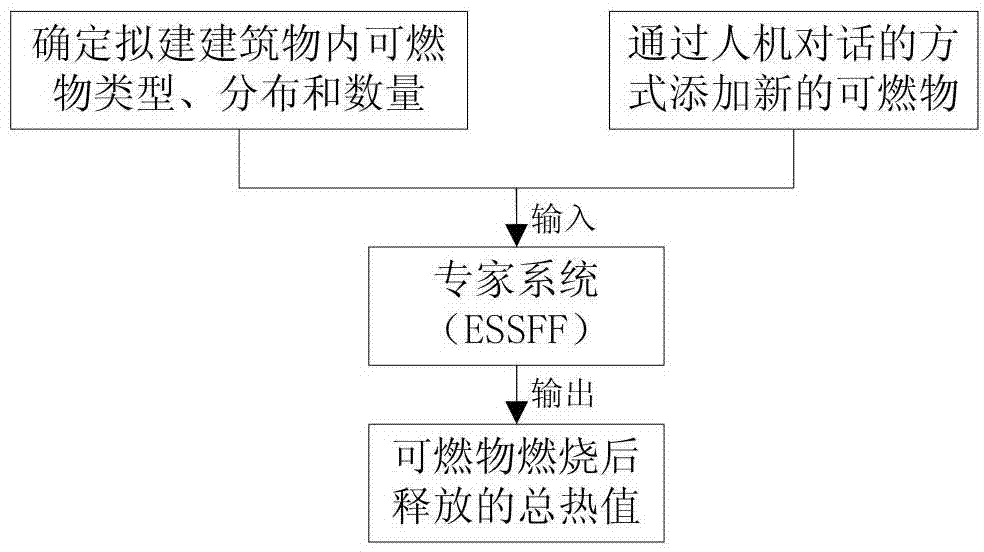

[0057] designer according to image 3 To operate, input the type, distribution, and quantity of combustibles in the proposed building into the expert system. If there is no such combustible information in the expert system information database, it can be added to the expert system through human-computer interaction, so that the proposed building can be calculated. The total calorific value released by the combustion of combustibles in buildings; according to Figure 4 Carry out the operation, input the information such as the total calorific value released by the combustibles of the proposed building, the area of the fire room, and the thermal inertia of the fire room into the expert system, and the fire load density in the proposed building can be calculated; according to Figure 5 To operate, input the fire load density in the proposed building and the opening ...

Embodiment 2

[0061] This embodiment introduces in detail the fire-resistant design of the steel structure after fire.

[0062] Figure 9 It is a flow chart of building structure treatment after fire; Figure 10 It is a flow chart of damage assessment of steel structure buildings after fire; Figure 11 The content of damage assessment of steel structure buildings after fire includes three parts: component identification, subunit identification and identification unit identification, and each part also needs to evaluate safety, usability and reliability; Figure 12 For the content and process of fire scene survey, according to Figure 12 Operation, you can understand the situation of the fire scene; according to Figure 13 After the fire site investigation is input into the expert system, the maximum temperature of the structure after the fire and the temperature field distribution of the structure after the fire can be obtained, and then the local damage and overall damage of the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com