A liquid air refrigeration power generation device for a data center and its working method

A technology for liquid air and power generation devices, applied in gas turbine devices, refrigerators, refrigeration and liquefaction, etc., can solve the problems of low power generation efficiency, no use value, unavailability of hot water, etc., and achieves reduced operating costs and strong power generation availability. , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

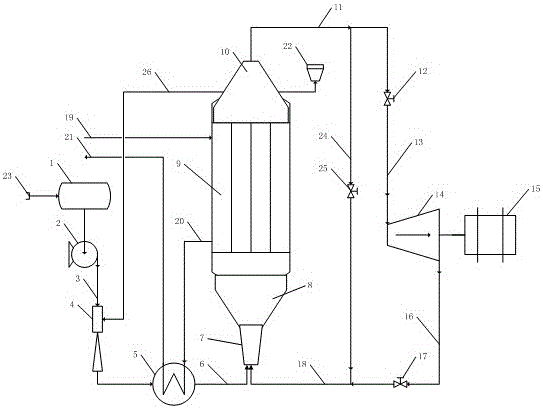

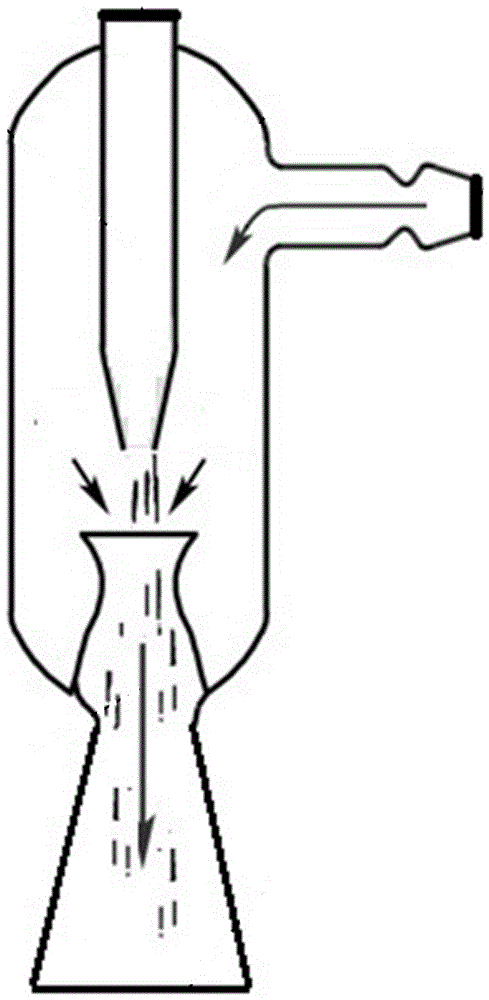

[0038] refer to figure 1 ,like figure 1A data center liquid air cooling power generation device shown in the figure includes: ultra-low temperature liquid storage tank 1, high-pressure ultra-low temperature liquid pump 2, high-pressure ultra-low temperature pipeline 3, jet diverter 4, low-temperature heat exchanger 5, low-temperature and high-pressure gas pipeline 6. Gas mixing diverter 7, temperature-increasing pressurized entropy supplementary heat exchanger composed of gas expansion section 8, medium temperature heat exchanger 9, and gas contraction section 10, normal temperature working gas pipeline 11, gas turbine input valve 12, working gas Road 13, gas turbine 14, generator 15, exhaust gas path 16, gas turbine output valve 17, return air line 18, cooling return water input line 19, medium and low temperature heat exchanger connection line 20, cooling return water output Pipeline 21, residual gas discharge port 22, liquid air filling port 23, maintenance short-circuit p...

Embodiment 2

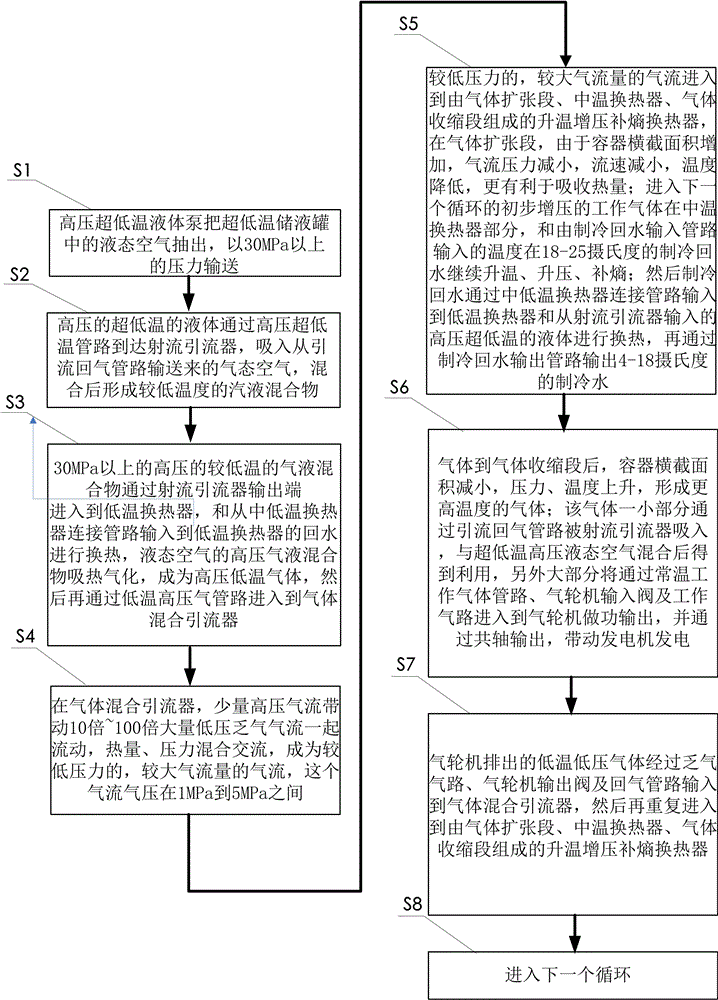

[0042] refer to figure 2 ,like figure 2 A working method of a liquid air working medium refrigeration power generation device in a data center includes the following steps:

[0043] S1, the high-pressure ultra-low temperature liquid pump 2 pumps out the liquid air in the ultra-low temperature liquid storage tank 1, and delivers it at a pressure above 30 MPa;

[0044] S2, the high-pressure ultra-low temperature liquid reaches the jet diverter 4 through the high-pressure ultra-low temperature pipeline 3, sucks the gaseous air transported from the drainage return pipeline 26, and forms a lower temperature vapor-liquid mixture after mixing;

[0045] S3, the high-pressure, relatively low-temperature gas-liquid mixture above 30 MPa enters the low-temperature heat exchanger 5 through the output end of the jet diverter 4, and exchanges with the return water input from the medium-low temperature heat exchanger connecting pipeline 20 to the low-temperature heat exchanger 5 Heat, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com